Vibrations, collisions and noises contribute to the bad operation and to the premature deterioration of machines and of structures, as well as to the pollution of the environment. Also human health is negatively influenced by such phenomena, with consequences that are more and more becoming the focus of managers responsible for safety.

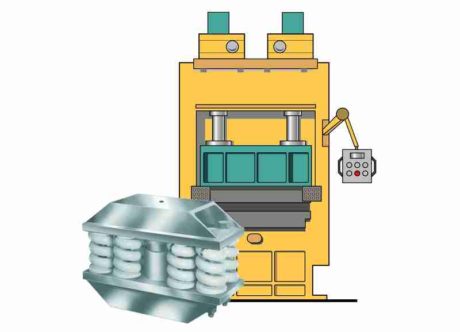

The Italian company Pantecnica, traditionally working at problems connected with mechanical vibrations, offers a range of anti-vibrating solutions that includes steel spring systems arranged in various typologies. The ASONATOR/IFB typology, produced in 32 sizes, satisfies needs of single load included between 5,800 and 41,000 kg.

The structure of these systems is constituted by multiple steel springs with high transverse rigidity, interposed between two shaped plates and undergoing painting in light gray colour (RAL-7035) for a durable resistance to corrosion. The springs are treated with shot-peening and lacquering to obtain the utmost warranty against the surface micro-cracking. Each system is provided with four bolts that compact the whole and act as preload tie rods; as a matter of fact, excluding different requests, these systems are supplied preloaded at a height slightly inferior to that corresponding to the minimum load suggested in the technical card.

To facilitate the installation, the supply preload is fixed by the producer at the height demanded by the customer and related to the expected operational load. After the installation, loosening the preload, the reaction of the springs creates the structure of the mass above. Under load, thanks to the elastic deflection of steel springs, you achieve low natural frequencies, ranging from 2.8 to 4.1 Hz (170÷245 cycles/min); this implies that, with appropriate ratio between natural and excitation frequency, you can obtain excellent vibration isolation degrees, up to 87%.

With the Asonator-IFB version, without viscous dampers, you only obtain the vibration isolation; to attain also the damping of the energy of mechanical vibrations as well as of shocks determined by operations or by resonance effects, the producer proposes the Asonator IFB/D, in which steel springs are aggregated to one or more viscous dampers. With this solution, together with high isolation degrees of mechanical vibrations, you attain also the damping of the same and of vertical shocks. In the generality of applications, it is worth highlighting the need of dissipating also the structural frequencies that can be transmitted through solids, by means of springs and preload tie rods; this need can be solved by applying between Asonator and the supporting surface (floor) a plate made of dissipative and bituminous material, with adequate resistance to load and acting also as contrast seizing element to possible transverse thrusts. These systems in the IFB and IFB/D versions, having the same height in all dimensions, feature total interchangeability.

They prove to be ideal for the isolation of machines and systems of notable heaviness and active in producing vertically striking forces, and generally operating for the sheet metal machining: eccentric and non eccentric presses, drawing presses, shearing machines, benders, flatteners, hammers, inertial masses and so on.

In some situations, by applying Asonator IFB or IFB/D you can achieve important savings: for instance, by avoiding the installation of expensive “inertial masses” as beds.

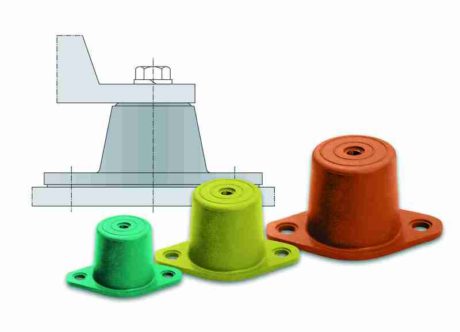

Vibration isolators

These anti-vibrating elements are proposed by Pantecnica Spa that suggests their use for the suspension of medium-large fans, blowers, machines and systems for the air conditioning, compressors, pumps etc. They are elements produced in compliance with the corporate quality management system according to EN ISO 9001 and the environment protection in conformity with the EN ISO 14001 regulation.

Their suitability for isolation, which is not limited to the above mentioned applications, is particularly referred to vibrations acting vertically.

The isolator body is made of homogeneous elastomer and has tubular truncated-cone shape; as such, it performs suitable gives for high isolation degrees of “active” and “passive” vibrations in a wide range of frequencies, also structural, as well as a good damping degree of the energy of vibrations themselves and of possible shocks. Generally speaking, an isolator constituted by elastomer with 55°Sh A hardness undergoing vertical static loads ranging from 50 to 100 daN, is affected by elastic deflections included between 4 and8 mmand consequently, it realizes own frequencies included between 7.8 and 5.6 Hz.

Metals, being completely coated by the elastomer, are protected against the environmental corrosion.

These isolators are produced in three different sizes, each of them with the elastomer in three different hardness typologies (40-55 and 70° ShA); they are easily identifiable according to the colour: green, red and beige, respectively. The producer puts at disposal a technical manual referred to its full range of rubber and rubber/metal vibration isolators and offers total collaboration in the choice of the most suitable and effective solution.