Getting the suitable equipment for knowing what actually happens inside a hydraulic circuit.

The troubles that may occur during the setup of a new hydraulic circuit on a machine can be manifold, sometimes owing to unexpected transient phenomena that cannot be detected by the manometer. Likewise, during an after sale service intervention the work to be carried out to discover the causes of the failure might be notably inferior if we knew precisely the real functioning parameters inside the circuit. The availability of sensors and instruments to detect the essential magnitudes of a circuit is therefore essential to survey operation criticalities and to highlight anomalies otherwise not detectable (fig.1). It is then an intervention that certainly dramatically reduces the costs, often neglected, of the testing and of the after-sale service.

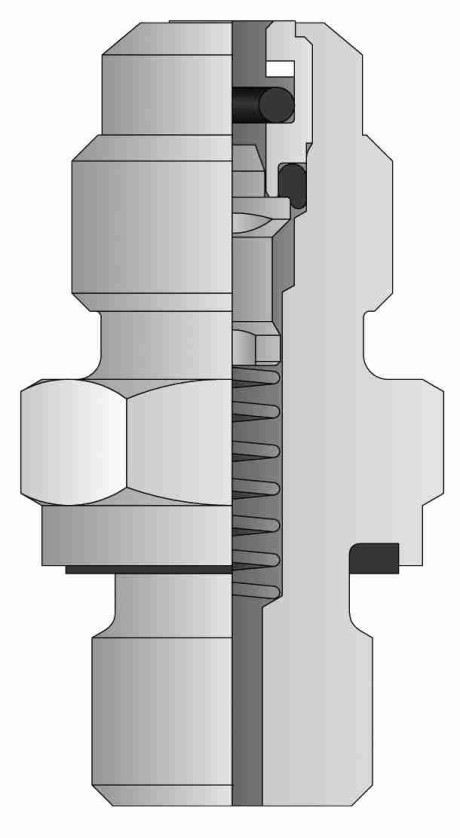

This sector is the focus of Hydrotechnik in Limburg (Germany), founded in 1964 and since then renowned as producer of Minimess © test point (fig.2).

Since that time the company has continuously designed and manufactured sensors and measuring instruments to detect the essential magnitudes that concern the operation of a hydraulic circuit. After Minimess ® – test point free from leakages for millions of cycles – in 1973 they devised the first of a long range of electronic measuring instruments. In 2005 the Italian branch was established in Saronno (Varese, Italy). Last year, Hydrotechnik sold more than 4 million units of Minimess ®, over twenty thousand sensors and about 1300 measuring instruments. The 2012 turnover reached 22 million Euros, mainly obtained in Germany (55%) and Europe (36%).

At customers’ service

Hydrotechnik Italia constantly operates to facilitate the adoption of these instruments in working ambits, paying constant attention to the training of users’ personnel, also with stages and training courses accomplished at customers’ headquarters. The collaboration is strict and aimed at identifying the problems and at finding the right solution, in order to obtain the best results. Utmost care is paid to the after sale service, with constant support to guide customers to the best use of the equipment bought, up to the remote diagnostics enabled by various measuring instruments. As additional service, Hydrotechnik offers also the service of calibration of customers’ sensors, even if manufactured by other producers, problem often neglected by lots of companies. Broad is the range of available sensors for the detection of real pressures, among which it is worth pointing out the PR400 sensor with 10 kHz frequency, able to detect pressure peaks lasting even only 0.1 ms. Besides, they are available detectors of flow rate, temperature and revolution numbers, as well as detectors of particles for the control of the fluid contamination and sensors of current and voltage on the electrical circuit. Vast availability of measuring instruments, too, designed by Hydrotechnik, for all requirements. All measuring instruments can house also sensors supplied by other producers.

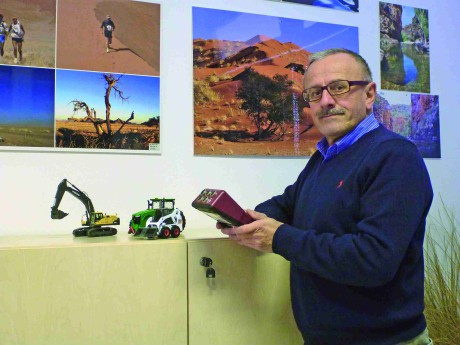

Face to face with Renzo Moltrasio

At the end of our visit, we asked some questions to Renzo Moltrasio, managing director of Hydrotechnik Italia.

How can we define your intervention sectors?

The company is present in all the sectors involving the use of hydraulic circuits: industry, motion, agricultural, aerospace, shipbuilding and military. Thanks to its complete production programme, Hydrotechnik succeeds in giving balanced answers to all the problems of detection, processing and filing of the physical magnitudes that concern a hydraulic circuit.

How is the market where you operate composed?

Our instruments are used in all sectors, starting from R & D departments up to the testing and the after sale service. The Italian market is becoming increasingly aware of these problems, in all sectors.

How are you dealing with a market, like the Italian one, suffering from the long-lasting crisis?

We have chosen a very clear way: absolute willingness to satisfy customers with concrete analyses and solutions for the specific problem and assiduous and constant after sale service.

How has customers’ approach to this kind of equipment changed?

There is always an initial detachment in the use of electronics. We have learnt to guide customers to the use of these instruments, to the choice of the most suitable components and to the processing of the collected data. Once the system has been tested, customers realize that they finally know perfectly how their machine operates and then they intervene with precision and promptness.

Which is the extent of your collaboration with your customer companies?

It is a world that is constantly growing, also thanks to our willingness of supporting customers in their entire course, up to our examination of the collected data or to the shared visit to their customers. We are already equipped also to receive data remotely from instruments installed by customers on their own machines and then to collaborate for the diagnosis.

What developments do you expect about the use of your instruments?

On a world scale we have already signed global agreements with big companies that are both manufacturers of hydraulic components and of machines. Due to these contracts, we have prearranged customized kits of sensors and instruments that are already produced with the colours and the codes of our customer and are arranged according to their requirements. This approach facilitates the whole after sale service chain that can rapidly compare the collected data with the standards provided for by the corporate design.

Besides, we are working to develop our own data transmission system permitting the remote data survey on a machine and the remote diagnostics processing.

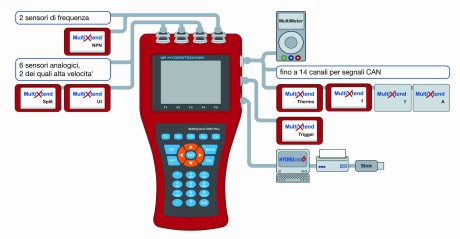

MultySystem 5060 Plus

It is the leader instrument in the Hydrotechnik production, with great use potentialities (fig.4).

It is provided with six analogue channels (two of which at high speed: 10,000 values per second) and two digital ones, fourteen CAN signals, USB port, programmability of calculation formulas.

The instrument is based on easy sequential programming, it groups the values of all sensors (including the particle counter) and it provides a table of the collected data or a graph with the value trend, on the display or through USB directly on the monitor of the computer.

The data can be saved (it has a SD card with a memory of 2 GB) or transferred on an external USB key or on PC.