The Italian company Interfluid presents a broad range of novelties for hydraulics, for both cutting-edge products and services. We talked about that with Roberto Sala, Company’s Founder, and Giampaolo Sala, Managing Director.

From small distributor of pneumatics products to international reality operating in 3 industrial sectors: hydraulics, pneumatics and high pressure. We interviewed Roberto Sala, founder of Interfluid, and Giampaolo Sala, Managing Director, on the occasion of the visit of Michael-Otto Eckerle, owner of Eckerle, one of the most important brands represented by the company. «We are distributors of renowned brands, such as Atos and Veljan, and we have our own line of piston pumps, Hydraut», explains Roberto Sala, «but for the sector of internal gear pumps we have relied for a long time on the consolidated relationship with Eckerle that has allowed us to start establishing a network of new relationships and to supply customers with a product hardly available on the market, completing it with a quality service». Among the outstanding recent novelties by Interfluid, in fact, there is the implementation of a test bench that allows granting tests, testing and safety certifications. «We think this service can offer a very important added value to our customers. Moreover, we rely on an internal assembly system, connected with a product configurator, which allows us to grant very fast deliveries in all Europe. Each product is always accompanied by the results of the tests we execute in our headquarters». Moreover, in virtue of a very recent agreement, Interfluid has become distributor of Kawasaki, initially focusing its efforts on the K3VL pump and on the Eco Servo system.

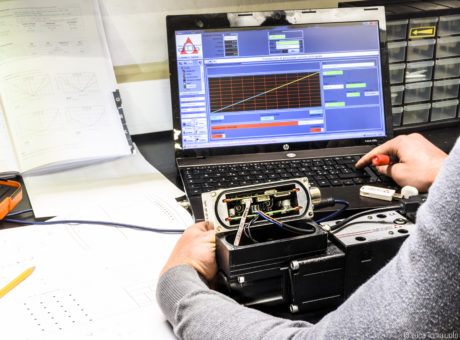

The guarantee of an in-house test bench

Interfluid intends to represent not only a distributor but also a reliable partner to which turning during the entire life cycle of the product. «Our new test bench allows us to test both fixed and variable displacement pumps in open circuit, as well as on/off proportional valves and other products, through the secondary dedicated circuit», explains Marco Sozzi, head of Interfluid hydraulics division.

Engineered by Interfluid technicians, the test bench has been studied to satisfy the requirements of production and quality guarantee of the products assembled internally, as well as to assure a professional cutting-edge after sales and customer care service. The bench performs the test of fixed and variable displacement single-stage pumps (double and triple simultaneously). «The idea of an internal test bench sprang from the more and more frequent demands for pump handling and today it allows us to propose the company as system integrator under all respects».

The main circuit allows verifying the nominal flow rate of pumps, by means of a flow meter, and controlling the circuit pressure through a proportional control valve. Piloted by a control panel equipped with touchscreen, the test bench allows visualizing in real time the data of flow rate, pressure, oil temperature, power current and torque absorbed by the electric motor, revolution number. An auxiliary group, equipped with autonomous motor pump, is instead dedicated to the test of valves, solenoid valves and proportional valves. The dedicated data acquisition software can detect all useful information for the processing of detailed graphs that describe the test carried out.

First Atos Service Center in Italy

Still with the aim of providing an all-round service to its customers, Interfluid has recently become, unique in Italy, Atos Service Centre: it can supply a technical support on proportional valves, both analogue and digital, before and after sale. Interfluid engineers know in detail Atos components and the operation of hydraulic systems. The Gallarate company supports users with a fast high-level service, minimizing machine downtimes. Interfluid expert technicians can overhaul, inspect, repair and test all the components of Atos product range.

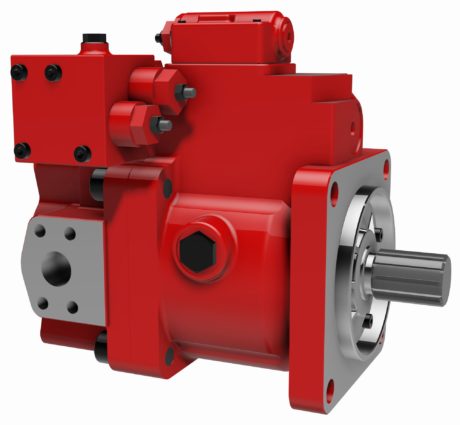

Hydraut piston pumps: service at the core

Interfluid is also distributor of Hydraut-branded piston pumps, a valid alternative to the more blazoned brands, dedicated to the manufacturers of hydraulics power units, machine producers and to maintenance centres. In the broadness of Hydraut product range, Interfluid stakes in particular on two lines: the piston pumps of the series HSP, from 18 cc to 140 cc, interchangeable with all Rexroth variants and those of the PQ series, smaller, from 10 to 70 cc. «For Interfluid, service is the core of any corporate procedure but in the case of Hydraut products it is particularly relevant because it constitutes the main advantage of these pumps. Our technicians support customers along the whole process: in the pre-sale phase, they analyse customers’ requirements, they proceed to the sizing, the comparison with competitors’ codes and the test on the test bench until the prompt delivery to the customer», explains Giampaolo Sala. Assembled and tested in Gallarate premises, Hydraut pumps are guaranteed for 18 months and they constitute a flexible solution due to the handling possibility offered by the internal test bench, an excellent compromise between quality and price, with an always-available consulting service. «Our broad network of component suppliers, reliable and verified in time, will soon have a further competitive edge. Next months, our product configurator will be in fact available online and will allow executing feasibility analyses in real time, notably improving the service supplied to final customers».

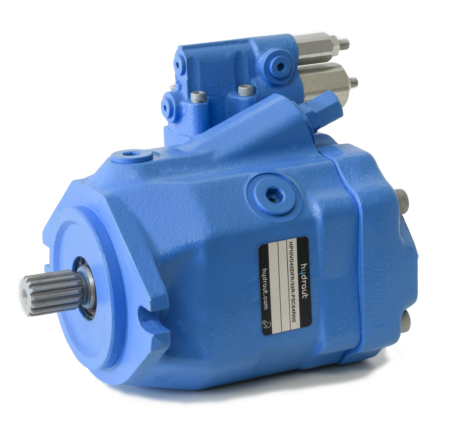

Eckerle internal gear pumps: low noise, small spaces and highest efficiency

The service quality is the thread also of the collaboration relationship between Interfluid and Eckerle, established for the distribution of internal gear pumps on the Italian market. Today more than ever delivery terms are fundamental and being able to deliver in short terms has been a noteworthy competitive edge. «Today the market is faster and faster, for this reason the experience of Eckerle in the sector was the key for us to enter a market segment that previously belonged to a single manufacturer», explains Giampaolo Sala. The history of Eckerle starts in fact in 1935 when Otto Eckerle, father of the current owner, established the first factory in Malsch, in the Black Forest. «The destruction of the factories occurred during the Second World War – tells us Michael-Otto Eckerle – was a heavy blow to the company that however succeeded in recovering thanks to a series of innovative patents». Due to the constant technological research, in the Sixties they developed the first internal gear pump of the series IPH, which was patented in 1968 and became renowned on a world scale. «These years of growth were followed by a period of uncertainty, caused by the choice of selling the company’s hydraulics division that led, in time, to an unavoidable loss of the basic principles of Eckerle’s history. For this reason, my father decided to undertake the risky enterprise of buying back the company and of starting a renovation course that lasts still today».

Nowadays Eckerle counts more than 200 patents where quality is the steady point. The German company’s internal gear pumps are in fact characterized by high efficiency, low noise and wide speed range. They are pumps used to operate at constant pressure up to 350 bars (depending on the size) and are used in various industrial sectors: machines for plastic materials, die casting machines, machine tools, presses and so on, or in vehicle that operate in a closed space, like electric forklifts. The high efficiency values connected with the compensation system, both radial and axial, allow reaching high efficiencies and a significant reduction of flow rate and pressure pulses. The internal gear pump is very versatile and also able to operate with very dense fluids.

The excellent distribution of loads and the particular bushing bearings allow operating at high pressures in constant operation and confer long service life to the pump. Compared to the vane pump, the internal gear pump is characterized by the almost constant flow rate despite the pressure variation (also at low revolution number), which instead does not happen for the vane pump. Moreover, in this application, unlike the vane pump, it is often used in the single-stage version, with much higher performances and efficiencies and lower noise. The particular mechanical structure of the pump gears grants a pulse-free flow rate, low noise and working pressures up to 350 bars. The compact design of Eckerle internal gear pumps allows the installation in narrow spaces.

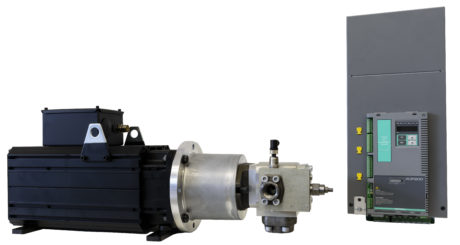

PIISMA: the hydraulic servo-pump for energy saving

Piisma variable-speed drive system, designed by Interfluid, provides the plant where it is installed with a series of significant operational benefits. The device consists of a variable-speed servomotor controlled by inverter, coupled with an internal gear pump with constant flow rate, whose power can be adapted to the requisites demanded by the machine cycle, to eliminate almost totally the energy losses with idle machine. In practice, when the machine is not executing any motion, the pump motor stops, too, with a notable impact on energy saving and efficiency.

Through the internal drive software it is possible to manage automatically a closed-loop control of flow rate and pressure with extreme precision. Piisma allows obtaining an energy saving up to 80%, regulating the revolution number and the pressure depending on the machine cycle and the real operation requirement, simplifying the plant. The main advantages include also the elimination of all proportional valves, the reduction of the tank volume up to 80% and noise to even 20 dB during the machine cycle and by 100% during the cycle pause. Moreover, the system allows a longer duration of the pump, maximum repeatability of flow rate/pressure parameters, higher system efficiency, minor heating of the oil and of the surrounding environment, reduction of overall dimensions by over 60%, reduction of the overall weight of the pump motor group. The device can be installed on small and big size injection presses for plastic and rubber, both with circuit equipped with conventional pump and with circuit with hydraulics accumulators. The numerous installations already accomplished demonstrate the several advantages achievable in terms of high energy and process efficiency. The system is also ideal for hydraulic presses and die casting machines.

interfluid