Cmatic is an Italian company headquartered at Giussano (Monza Brianza), for over forty years it has been active in the design and manufacturing of pneumatic fittings. Research and innovation have always represented its distinguishing character, since the foundation, at the behest of Orazio Confalonieri and today, thanks to an excellent specialization level, it ranks in the forefront on a world scale with its automated high-quality fittings, at the service of manufacturing enterprises of industrial machines in the most various sectors.

The reference list of Cmatic customers includes, in fact, companies specialized in Food & Beverage, due to NSF169-certified fittings in compliance with European and MOCA standards for the materials in contact with food, as well as the producers of lines dedicated to the transport sector with TÜV certification and for pneumatics (guaranteed as free from silicon oils and Reach- and RoHS-compliant), but also those enterprises demanding ranges purposely studied for the requirements of automated distribution, of lubrication, of hydraulics, of nebulization and of Chemical & Pharma, such as the brand-new line of Clamp XT connectors, fully made of stainless steel, NSF/ANSI 169 certified and sized according to ASME BPE standards.

Made in Italy

The corporate production includes standard automatic fittings, compression fittings, push-on and function fittings; in addition to clampings, safety clampings, multiple connectors and clamp-type connectors.

A broad range that makes up a product catalogue including over 40 families of fittings, in 5000 variants that differentiate one another by sizes, measures and application ambits. In the field of fittings, Cmatic is one of the few companies on the market that can grant the tailor-made product manufacturing and therefore, besides having the possibility of choosing among standard ranges, customers can also demand for the modification of materials, sizes and threads, which the enterprise can grant as it can rely on the direct management of each phase of the manufacturing chain, which is fully accomplished in Giussano factory, hosted in an area taking up 8500 sq.m., where every year over 20 million parts are produced and inside which more than 100 employees daily work.

R&D as strong point

Moreover, corporate headquarters house the Cm-Lab, modern laboratory of Research & Development where, besides carrying out the tests of its products, even under extreme conditions, innovative solutions are constantly analysed and designed for each application ambit, by means of forefront equipment allowing the compliance with the highest standards.

Therefore, starting from Brianza, Cmatic fittings reach Italy and foreign markets, due to a policy of strong internationalization undertaken along the years by the company, which operates worldwide, also through two logistic business centres located in Ohio and in Shanghai. Starting from headquarters, in time the company has paid utmost attention not only to the quality of the product and relative processes but also to the protection of workers’ health and environmental sustainability. Concerning this, the last example is the ISO45001 certification, highest international standard about health and safety, achieved in 2021 to join ISO9001 certifications for the quality management system, existing since 1994, and ISO14001:2015 about the environmental management.

The new EV10

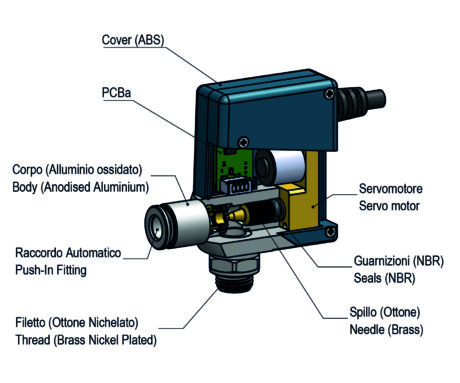

Among the novelties launched by Cmatic in recent months, an important role is played by the field of function fittings, due to a broad range of devices to grant the control of the airflow and of its direction, or of solutions able to partialize the flow rate. The new electronic proportional flow control, with double analogue and digital interface, belongs to this EV10 family. A particularly suitable product in processes that need great precision and reliability in set-points, whose operation principle is based on the discretization of the needle valve stroke in a precise positioning number managed by a stepper motor.

EV10 consists of a PCBa that, reading the electric input signal, reprocesses it, sending a control signal to a servo actuator. Therefore, the latter can move the needle valve positioned inside an orifice to make a linear flow rate change proportional with the electric input signal. The control modality of the electronic board is established by PLC and two different interface typologies. The first, analogue, works through an input signal included between 0 and 10 Vdc. The second, digital, uses a two-wire connection via RS485, through a communication protocol in conformity with Modbus standard. EV10 electronic proportional flow control is proposed with automatic fitting in 6 mm, 8 mm and 10 mm diameters, which can be adapted to G1/8”, G1/4”, G3/8” and G1/2” threads, with as many ranges of maximum flow rate (420 Nl/min, 700 Nl/min, 1150 Nl/min). Three are the configurations provided, respectively with bidirectional operation and regulation, unidirectional operation, input regulation and unidirectional operation, output regulation. With IP40 protection degree and equipped with EC marking, this product finds application with variable operation temperature conditions (from 0°C to +50°C), and it is compliant with “RoHs” directive and European “REACH” Regulation, too. The main technical specifications are completed by linearity (max ± 1% f.s.), positioning repeatability (± 0.5% f.s.), hysteresis (max 1% f.s.), and sensibility (0.25% f.s.).

EV10 consists of a PCBa that, reading the electric input signal, reprocesses it, sending a control signal to a servo actuator. Therefore, the latter can move the needle valve positioned inside an orifice to make a linear flow rate change proportional with the electric input signal. The control modality of the electronic board is established by PLC and two different interface typologies. The first, analogue, works through an input signal included between 0 and 10 Vdc. The second, digital, uses a two-wire connection via RS485, through a communication protocol in conformity with Modbus standard. EV10 electronic proportional flow control is proposed with automatic fitting in 6 mm, 8 mm and 10 mm diameters, which can be adapted to G1/8”, G1/4”, G3/8” and G1/2” threads, with as many ranges of maximum flow rate (420 Nl/min, 700 Nl/min, 1150 Nl/min). Three are the configurations provided, respectively with bidirectional operation and regulation, unidirectional operation, input regulation and unidirectional operation, output regulation. With IP40 protection degree and equipped with EC marking, this product finds application with variable operation temperature conditions (from 0°C to +50°C), and it is compliant with “RoHs” directive and European “REACH” Regulation, too. The main technical specifications are completed by linearity (max ± 1% f.s.), positioning repeatability (± 0.5% f.s.), hysteresis (max 1% f.s.), and sensibility (0.25% f.s.).