Teseo has recently widened its range of aluminium section tubes of the AP series with the new 36 diameter. Another interesting novelty is the “plug & play” flow meter, which allows collecting data to assess the operation and the performances of a plant. The floor to Paolo Nardi.

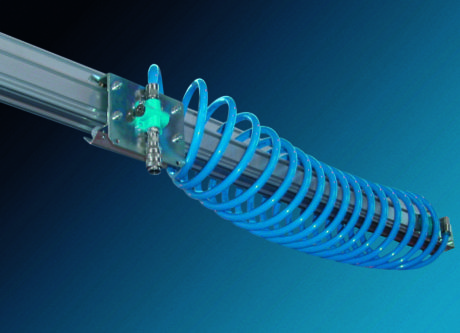

The AP aluminium section tube with 36 diameter is one of the products highlighted by Teseo. «This product – explained Paolo Nardi, sales manager of Teseo – completes the AP (Aluminium Pipework) range developed by the company, a modular system of extruded aluminium section tubes with innovative characteristics and high performances».

The new AP section is 30% lighter than the corresponding model of the HBS range, with equal flow rate and pressure drop performances.

Thanks to the innovative design and the broad range of accessories, the tubes of the AP series are devised to speed up the assembling and the plant modifications even when the work is accomplished. They can be installed easily and safely on equipment of common use, without threading, welding or painting anything. All the four faces of the section tube are usable to apply output plates or for eventual hanging points. State-of-the-art joints take benefit from a drastic reduction of fastening screws. Several parts are interchangeable to facilitate the modifications and the evolution of the modular system.

Inside the AP range, it is worth pointing out also the 68 diameter, available also in 45° and 90° curved version, or with special angles and shapes on demand. A new series of mounting brackets grants a fast assembly. The DT drilling accessory allows creating new use points by drilling the pressurized line easily and safely.

With equal nominal diameter, the AP system aims at granting bigger flowrate and a lower pressure drop, characteristic that results in high performances without energy wastes. Teseo extruded pipes are made of natural aluminium, without painting or surface electrochemical treatments. In this way, the product is easily recyclable. The patented clamping system allows the dismounting and the easy use of all parts.

The aluminium used for Teseo section tubes is subjected neither to corrosion nor to oxidation, granting the quality of the circulating air and consequently the healthiness of the plant and of the instruments connected with it. The maintenance is scarcely invasive, both in terms of time and of cost.

The upgraded range AP by Teseo has been studied to reduce costs under several respects. The sealing system with double O-ring eliminates air leaks, thus granting energy savings. Machine downtime and labour costs decrease to the few necessary minutes for the addition of an output plate for a new machinery or a use point. More than any other black or galvanized iron tube, the smooth surface of extruded aluminium tubes reduces friction. The air flows inside, minimizing the pressure drop and granting higher flowrate with the same electricity consumption. Moreover, the AP section tube is 70% lighter than its corresponding iron version.

Teseo supplies also the Cent80 pipe bender, tool that can satisfy quickly and cheaply the bending requirements of the various plant types. This tool allows performing manually all bends up to 180°, in yard or in other contexts.

A new flow meter

«Another interesting novelty is the “plug & play” flow meter, based on state-of-the-art VP technology, integrated with Teseo pipework» specified Nardi. «This integration allows creating smart systems, i.e. compressed air distribution systems able to provide information in real time about their operation». The probe, installed on Teseo system, can detect the flowrate, the temperature and the pressure inside tubes. The collected data will allow evaluating the operation and the performances of the plant.

«At any time, the system can inform the factory technicians and maintenance supervisors about the behaviour of the system itself, the consumptions during the day or in a well-defined lapse of time» specified Nardi. «Integrating these types of devices into strategic points of the plants allows evaluating costs, monitoring eventual failures or malfunctions and assessing how much the compressed air can affect certain operations, the painting or the assembly department».

With this and other products and services, Teseo supports the companies committed to the challenge of the energy consumption reduction and of the adoption of eco-sustainable behaviours. Improving the process efficiency, decreasing CO2 emissions are more and more important issues worth considering and the compressed air is a significant item among energy costs for companies, often not adequately considered, or even wasted or lost in the form of grid losses. For this reason, a new standard has been recently introduced for compressed air audits (ISO 11011) that compels technicians to consider the entire system (generation, distribution and use) to estimate its efficiency and operation.

Teseo, to support companies in these ambits, besides tubes and joints with double O-ring and instruments for the measurement and monitoring of consumptions, provides also an in-house design service able to conceive “energy saving” plants. The net of branches, distributors and technical partners can assist customers with competence.

Products for all requirements of the pneumatic sector

Among Teseo products, also the accessories for compressor chambers and the plants of the HBS range are worth reminding. Thanks to the new aluminium fittings, it is possible to create more compact bypasses, both for new installations and the upgrading of old plants. The new modular manifolds for compressed air, coolants and emulsions deriving from the special AP54 section complete a broad range for available diameters, accessories and solutions. To facilitate the design, Teseo provides designers of plants, engineering studios and machine manufacturers with a complete CAD library from which it is possible to enter information about section tubes, fittings and accessories of the AP and HBS lines, to create quickly the modular manifold or the special desired shunt.

«We are also launching our ergonomic line, products to fit out workstations» explained Nardi. «They are trolleys and rotary arms that allow feeding and supporting pneumatic tools». Target of these products is improving productivity, while increasing safety and reducing the operator’s labour, to create more favourable work conditions.

In the opinion of Nardi, the highlights that characterize Teseo and are particularly appreciated by customers include the product quality, aspect that results in high performances. A second aspect is represented by the service quality and by prompt delivery terms for medium-large plants, too.

A company in constant evolution

With headquarters at Desenzano del Garda (Brescia, Italy), Teseo, established in 1988, stood out, among the first in the world, in the development of a modular aluminium system for the distribution of compressed air and other technical gases. Today, after almost thirty years of activity, the company employs around sixty workers, 35 of them in Desenzano and the others in foreign branches.

Today the company is present with its subsidiaries in Germany, Great Britain, Spain, Holland and Canada. «Where we are not present with a branch, we avail ourselves of a net of independent distributors» said Nardi. «The European coverage is very good, in each Country operates at least one authorized distributor. Teseo sales organization is in expansion in Central and North America, in Middle East and in other Asian areas».

Teseo relies on an in-house technical division and on a test lab for tests and prototyping. The products and the quality system are certified and controlled by international bodies, like Kiwa and SGS. «We are committed to the research and development ambit as well» underlined Nardi. «We are working at the development of a wind compressor, a machine that produces compressed air powered by the wind, a wind turbine. The idea of producing energy as close as possible to the power supply point inspired this kind of project.

We must try to convert energy with the least possible number of steps, therefore in this case a turbine driven by the wind directly operates the shaft of a compressor. Thanks to this project, we have gained knowledge concerning wing contours and the condensate management under particular use conditions of the compressed air. This specific project brings experience that we can use in other ambits and allows widening our technological expertise in the compressed air distribution».

In the opinion of Nardi, the compressed air issue will remain a topical theme in the future, too. «Someone would like to give it up but I believe that compressed air will be still important also in the future» ended the sales manager of Teseo. «The compressed air still provides several advantages because it is easily accumulated in a reservoir, simplifies the process automation thanks to the pneumatic automation that still grants wide application spaces».

Today Teseo systems are installed in small, medium and big companies worldwide, especially in textile, electronic, mechanic and automotive industries. Twinings and Brembo are among the companies that have chosen Teseo.

We are looking for Genuine supplier for your products in INDIA

we will be highly obliged if you can inform us contact number of your dealer/ agent / representative in Indie