With the new SAM Series the range of Linearmech electromechanical servoactuators is now complete. Linearmech is the Servomech brand with a specific focus in automation and mechatronics, also applied as alternative to pneumatics. With respect to the more traditional systems, the Linearmech servoactuators adopt innovative solutions, combining in the best way the requests for higher performance and higher productivity of the production plants with competitive industrial costs. Ideals for applications with highly dynamics conditions, high precision and repeatability and reliability over the time. All the servoactuators are equipped with high precision ball screw linear drive unit made by Servomech. They are characterized by low inertia, absence of play and ensure high positioning control.

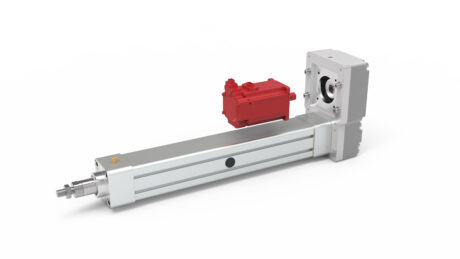

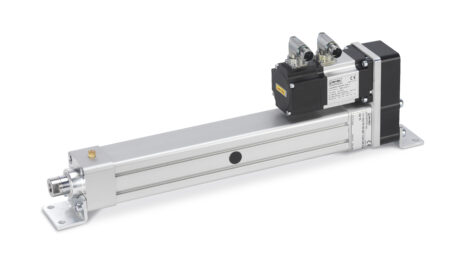

The new SAM series is characterized by Servomech’s high-performance mechanical linear unit already widely tested in the SA IL and SA PD series, electromechanical servo actuators complete with brushless servomotors. All the internal components are designed and built by Servomech to achieve the maximum performance. High linear speed, low inertia, extreme precision and repeatability during positioning control, reliability and durability over the time.

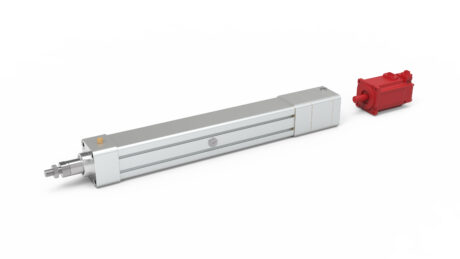

Today the new SAM series expands the possibilities of use, leaving the customer the freedom to choice motor and drive. The mechanical linear unit is designed for mounting commercially available servomotors. Now available with parallel and line design motor configuration.

All servo-actuators are provided with a wide range of fixing elements according to the ISO 15552 standard of pneumatic cylinders, for a total and simple interchangeability with the existing pneumatic units. In addition to the new SAM series, also available complete configurations with servomotor in-line mounted SA IL series or servomotor parallel mounted SA PD series. Seven different sizes available, with linear speed up to 1500 mm/s and peak force up to 46 kN.

The advantages applied to multi-axis systems

In the industrial field, examples of machinery with multiple axes are widespread: among the most common folding machines, labeling machines, packaging machines, industrial printers, textile machines, presses. In such systems, the synchronism of motion is often a necessity. The axes must work under the precise control of speed, but also precise control of position and applied force. Manufacturers invest in the renewal of machinery in the face of market demands based on production speed-up and flexibility. Increasingly higher performance is sought in terms of frequency of operations performed, precision and reliability in the execution of movements. In addition to this, machinery maintenance, energy consumption and time-saving are determining factors in the innovation process.

To best combine all these requests, Servomech summarizes its proposal in the new series of electromechanical cylinders with servomotors. In an industrial context where the customer’s request is often for small and fast productions and reduced changeover times, overcoming the limits of traditional mechanical systems for transmission of motion, such as shafts, complex kinematics, cams and belts to the advantage of an electronic synchronism control has significant implications from a performance and economic point of view.

Servomech electromechanical servo actuators with high precision ball screw can be individually motorized with brushless servomotors, characterized by compact dimension, excellent dynamic characteristics, higher efficiency and high power factor. The synchronism of the axes is guaranteed by a constant control of the encoder feedback mounted on the brushless motor. In the event of slowing down of one of the axes, a simple change in motion for all the others will keep the system synchronized. Thanks to a high precision mechanics construction, it is possible to manage a high position control. The characteristics of mechanical coupling in terms of the synchronism is therefore granted, with a great advantage in terms of improvement of the dynamic performance of the system.

Benefits deriving from the absence of mechanical coupling

There are many advantages deriving from the absence of mechanical coupling: there is no need for a systematic maintenance and other related problems such as a decrease in performance caused by wear of the components and in some cases the increased noise are therefore eliminated. There are also fewer masses involved, which means less vibrations, and the dimensions of the machine can be reduced for the benefit of greater compactness. Eliminating mechanical couplings also reduces the probability of breakage, together with the power dissipated along the chain of the various transmission components.

The absence of the physical motion transmission shaft eliminates two boundary conditions from the design, which now become parameters chosen by the designer: the moment of inertia and viscous friction. They can be varied as desired in order to obtain the desired specifications in terms of dynamics: more or less damped dynamics can be obtained, which in the physical case is not possible. All without dissipated mechanical power, another unattainable goal in case of physical connections.

One more advantage is represented by the reduction of the mechanical power required by the drives, which translates into a lower electrical power required by the network. All this entails a consequent energy saving for all the system, not a negligible aspect at all.

The operational flexibility introduced by these types of control translates into shorter setup times. In fact, for a change in the law of motion, in case for example of a change in the process, it is sufficient to act electronically. With physical connections, the mechanical implementation would have required significantly higher times and costs.