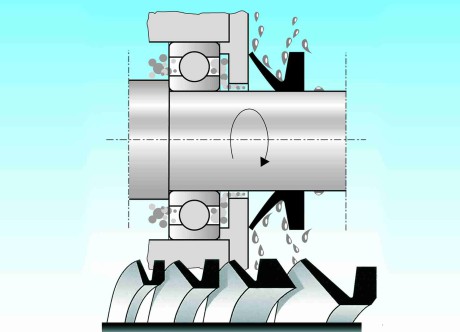

In the sealing on rotary shafts and rotating members, friction plays an important role because, besides wear, it causes heating and power loss. The friction elimination on the shaft is implemented by V-Seal sealing rings, with front instead of radial sliding, proposed by Pantecnica, for peripheral speeds up to 12 m/sec.  The peculiarity of their operation is based on the fact that the sealing lip does not slide on the rotary shaft but on a counter-face positioned orthogonally to the rotation axis. The ring body is stable on the shaft by elastic interference, it rotates with it and keeps the contact sealing lip controlled with the sliding counter-face. The centrifugal force that develops on the rotary sealing lip causes the filth ejection, preventing its entry towards the bearing or other mechanical member; the contact between sealing lip and the counter-face prevents the outflow of the bearing coolant. In some cases, the ring can be applied on the static part and perform the sealing on the rotary counter-face. With this type of assembly, the sealing lip, not being subjected to the centrifugal force, can develop the sealing action with high peripheral speeds, within the admitted limits, even keeping the pressure on the rotary counter-face constant. In the “Antifriction” version, the already modest friction is further reduced by 40%, with consequent reduction of heating and power dissipation. These seals, being exclusively constituted by homogeneous elastomer, without metal inserts, offer all the characteristics of the elastomer used; since they can be freely supplied in the NBR, FPM, EPDM, MVQ or CR elastomers, they are suitable for applications with temperatures included between -60° e +200°C and for the contact with wide ranges of aggressive chemicals; besides, they can also be supplied in compounds compliant with FDA (Food and Drug Administration) regulations. V-Seals are used in applications where it is necessary a protective sealing of rotary mechanical members against filth and dust, together with the coolant reduction in the pre-established seat; typical are the sectors of machine tools, agricultural machinery, for mining, papermaking, wood working and the machining of cylinders of rolling mills and so on, in a dimensional range that includes diameters for shafts from 3 to 2000 mm.

The peculiarity of their operation is based on the fact that the sealing lip does not slide on the rotary shaft but on a counter-face positioned orthogonally to the rotation axis. The ring body is stable on the shaft by elastic interference, it rotates with it and keeps the contact sealing lip controlled with the sliding counter-face. The centrifugal force that develops on the rotary sealing lip causes the filth ejection, preventing its entry towards the bearing or other mechanical member; the contact between sealing lip and the counter-face prevents the outflow of the bearing coolant. In some cases, the ring can be applied on the static part and perform the sealing on the rotary counter-face. With this type of assembly, the sealing lip, not being subjected to the centrifugal force, can develop the sealing action with high peripheral speeds, within the admitted limits, even keeping the pressure on the rotary counter-face constant. In the “Antifriction” version, the already modest friction is further reduced by 40%, with consequent reduction of heating and power dissipation. These seals, being exclusively constituted by homogeneous elastomer, without metal inserts, offer all the characteristics of the elastomer used; since they can be freely supplied in the NBR, FPM, EPDM, MVQ or CR elastomers, they are suitable for applications with temperatures included between -60° e +200°C and for the contact with wide ranges of aggressive chemicals; besides, they can also be supplied in compounds compliant with FDA (Food and Drug Administration) regulations. V-Seals are used in applications where it is necessary a protective sealing of rotary mechanical members against filth and dust, together with the coolant reduction in the pre-established seat; typical are the sectors of machine tools, agricultural machinery, for mining, papermaking, wood working and the machining of cylinders of rolling mills and so on, in a dimensional range that includes diameters for shafts from 3 to 2000 mm.