Relying on intellectual property, expertise and in-house production means to approach the market as privileged partner. Servomech Group can boast this opportunity, transferring its added value under the form of higher competitiveness and constant product evolution.

When we mention Industry 4.0 or Smart Factory we immediately think of total automation, interconnection of the factory and of its production processes; we think of the so-called “cyber-physical” control systems, of the Internet of Things (better known as IoT, Internet of Things), cloud computing or, besides, of the data collection and the real time analysis of information in smart manner and with self-teaching functions. Why do we speak, however, of 4th Industrial Revolution? For what reasons are we wondering about these new dynamics? What is the new challenge to be won?

«The challenge – states Valentina Cataldo, marketing manager of Servomech Group– consists in rethinking the production with solutions and machines allowing companies to suit promptly the fluctuating market demand. This strongly increasing the possibility of customizing productions according to purchasers’ demands, of making the production flexible without stocking up while, however, always maintaining competitive prices».

This approach will unavoidably lead to a radical change of the invention, manufacturing, shipping and selling modalities of products.

«In short – adds Valentina Cataldo – providing the market with customized products that grant the same delivery terms and prices of standard products».

Concerning this, Servomech Group, headquartered at Anzola dell’Emilia (BO), operating for over 25 years in the production of linear actuators and mechanical screw jacks, has already undertaken numerous initiatives towards this specific direction.

«We have invested in new, innovative and technological products – adds Valentina Cataldo – precisely in conformity with the perceptions and the needs that the market has indicated to us. The pay-off of our 2015-campaign, “5 good reasons to go electric”, just interprets what the market demands today».

Efficiency, performances and accuracy

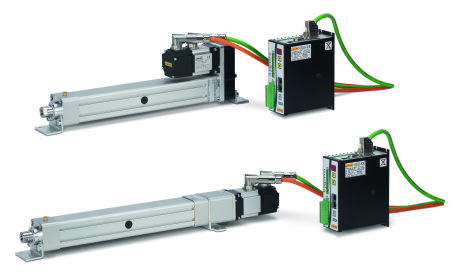

Referring to innovation and product evolution, the Group based in Bologna constantly releases interesting novelties on the market. Among them, also a range of powered electromechanical cylinders and a series of electromechanical servo-actuators, as the real alternative to hydraulic and pneumatic cylinders.

More in detail, the new range of motorized electromechanical cylinders constitutes a convenient technological innovation to solve the problems connected with the use of hydraulic cylinders. Due to their design and manufacturing, the new cylinders provide higher efficiency with lower energy consumptions.

«This is made possible – underlines Valentina Cataldo – by high efficiency, aspect that allows installing lower powers, consuming energy only during the operation. Besides, another distinguishing peculiarity regards the higher position/speed/force control, that is to say possibility of performing high speeds and loads under the precise and accurate position control».

Among the main strong points, it is worth highlighting also the positioning precision in the order of hundredth of millimetre, the very high repeatability, constant in time, in addition to better safety and reliability (no risk due to high pressures and no oil leakage, and possibility of receiving exact documented calculation concerning the component service life). Available in various assembling configurations for a total interchangeability with existing hydraulic cylinders, these new cylinders grant also minor installation and maintenance costs, and can be implemented in special executions designed according to specific requirements.

«Since only power supply and signal transmission cables are necessary – adds Valentina Cataldo – also connections are simpler and, absolutely not negligible aspect, even long periods without operation and maintenance can elapse and they are always ready to use».

High speed solutions with compact dimensions

Another novelty concerns, as already anticipated, electromechanical Linearmech servo-actuators, components that enable the traditional users of pneumatic cylinders to manufacture faster, more compact and more precise machines, reducing energy consumptions and controlling all axes in centralized manner.

«The new range of SA electromechanical servo-actuators – explains Valentina Cataldo – includes 3 different types of construction, that is to say the only linear unit without servomotor, or the complete package provided with servomotor produced by our company, with both in-line and parallel configuration, in the same linear drive unit and with a modular structure. Seven different standard sizes, designed to cover a wide range of performances».

With sturdy and compact structure, these servo-actuators are available with ball screws manufactured by Servomech (different precision classes at disposal depending on the specific applicative needs) and with a wide range of fastening elements according to the standard of ISO 15552 pneumatic cylinders.

Steeply rising “made-in-Italy” innovation

Product innovation, know-how, competences and total control of the entire productive cycle (fully in-house carried out) make Servomech Group a national and international reference partner in the production of linear actuators, acme screw jacks, ball screw jacks, bevel gearboxes, ball screws and nuts. Part of the Group is also Linearmech, division dedicated to automation and mechatronics, in 2010 become real productive reality with the aim of developing a new generation of servo-actuators, brushless servomotors and integrated drive and control systems.

«The Group – specifies and ends Valentina Cataldo – operates through two manufacturing sites, both headquartered at Anzola dell’Emilia (BO), where they employ about 100 workers, for an overall turnover of 13million Euros, whose composition is today destined by 60% beyond the borders: especially in the Countries of the Euro zone like Germany, Austria, Belgium, Holland and Denmark, as well as in Russia, China and Australia».

As confirmation of the importance held by investments and by the farsighted entrepreneurial vision, in the course of 2015 (work end scheduled next November) Servomech has programmed an enlargement plan of the current productive spaces of the two factories (about 9,000 square metres) with a third building taking up 5,400 square metres with exclusively productive destination. In the next five years, this growth will be completed by an integration of skilled personnel, estimated in about 40 new employees.

Serve the market with customized products, at price and delivery conditions as standard ones

In the context of a slightly recovering market, what is the trend and the health state of the field where Servomech Group operates?

«We notice a growth of interest, by both the home and the international market,– underlines Valentina Cataldo – in cutting-edge technological solutions that lead to increase the plant productivity and to reduce production costs. Our product novelties, introduced in the last 5 years, arouse markets’ satisfactory interest. We survey in particular that today markets strongly ask also for another component, in addition to innovative and technological products: technical and applicative assistance in the product choice and selection phase. This form of pre-sale customer service becomes more and more determinant for the diffusion and the success in markets».

Today markets pursue and demand for reliability in sale relationships, technical collaboration in product design and selection phase, besides, finally, the right price and fast delivery terms.

«From our point of view, the new challenge – confirms Valentina Cataldo – will consist in providing the market with customized products with the same delivery terms and prices as standard volume-manufacturing products».

For this reason, the current year is still in the name of investments and innovations.

«Innovation – adds Valentina Cataldo – that results in the introduction of new high-tech solutions, as well as in the widening of the range of existing products. An example? Inside the company, we rely on the technology and the know-how for the design and the production of ball screws and nuts, a core component for our production».

The introduction of this new productive technology and the possibility of implementing customized screws and nuts according to specific requirements has enabled the development of two innovations: the new range of Servomech ball jacks implemented with patented solution and the new generation of Linearmech electro-mechanical servo-actuators.

Native integration and patented technological evolution

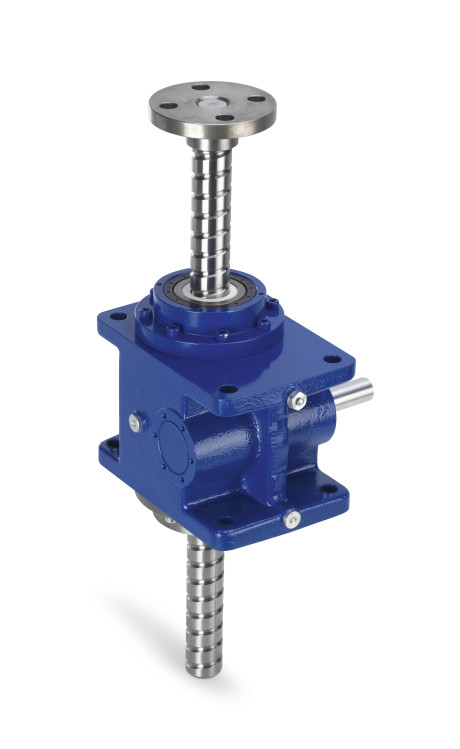

The novelties recently released on the market by Servomech Group encompass also ball screw jacks, solutions that overcome the applicative limits of acme screw jacks: high linear speeds, also continuous operation cycle, absence of nut wear and of the axial clearance, documented service life calculation, halved energy consumptions and installed powers. In particular, the solution with translating ball screw Series MA BS Mod. A is manufactured with an innovative patented design.

Thanks to the in-house Servomech design and production of all components (ball screws and nuts included) it was possible to design the native integration precisely of these two elements inside the screw jack body. The outcome gives birth to higher performances and better positioning precision as well as to more stiffness with compact overall dimensions.

The advantages that the market can draw from this solution are the following: immediate cost reduction thanks to an efficient optimization of products and performances, lower energy consumptions, higher load capacity with the same sizes, better structure rigidity thanks to the native component integration. These screw jacks are available in 8 sizes, with loading capacity from 5 to 350 kN, ball screw diameter from 16 to 120 mm, input speed up to 3,000 rpm, maximum linear speed of 2 m/s, with continuous use factor. The possibility of integrating mechanical Servomech screw jacks with the new series of Brushless Servomotors with IEC interface produced by Linearmech surprisingly widens the applicative scenarios of this product.

Linearmech drives are implemented by an Italian company and are perfectly integrated with Servomech brushless servomotors. Thanks to the specific mechatronic functions to manage even complex load and speed profile, the positioning control, the torque control and the speed control are very easy and simple to achieve.

Dear Sir,

Need catalog for Powered Electromechanical Cylinder with motor.

Thanks & Regards

R.Siva

9551425227

Dear Mr. Siva,

to receive the catalogue by SERVOMECH, you ca directly contact Mrs. Valentina Cataldo to the following address:

valentina.cataldo@servomech.it

Tel. +39.051.6501711

Best regards

Anna Bonanomi

Need your product data or catalog

Hi Albertus,

we are glad you appreciated the content of our digital magazine Power Transmission World.

We are not dealer of SERVOMECH components. For any request about Servomech products, you can directly contact the company to the following address:

Valentina Cataldo: marketing@servomech.com

Kind regards

Anna Bonanomi

editor

Hi Albertus,

we are glad you appreciated the content of our digital magazine Power Transmission World.

We are not dealer of SERVOMECH components. For any request about Servomech products, you can directly contact the company to the following address:

Valentina Cataldo: marketing@servomech.com

Kind regards

Anna Bonanomi

editor

Hi Albertus,

For any request about Servomech products, you can directly contact the company to the following address:

Valentina Cataldo: marketing@servomech.com

Kind regards

Anna Bonanomi

editor