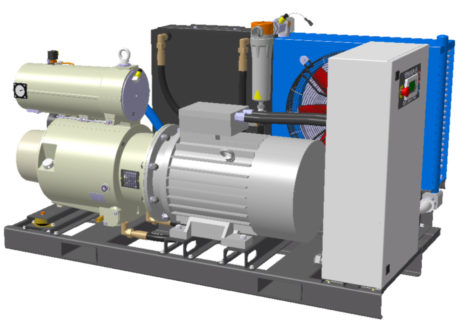

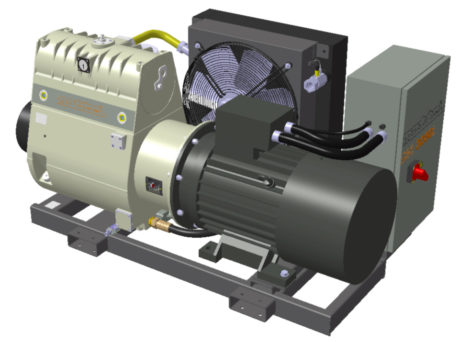

The experience of Mattei R&D division has developed special set-ups for aluminium foundries, based on the rotary vane technology.

Aluminium foundries are certainly among the industrial environments where the use of compressors is most subject to particularly harsh conditions of use. The rotary vane technology of M135 series compressors by Mattei, combined with an intense activity of the R&D division, has created high performing equipments even in these situations.

There are many critical elements which must be faced. Starting with the temperature, of about 30°C higher compared to other manufacturing environments, that reaches 90°C in the ridge of the factory building, i.e. where the compressors are generally positioned, due to the heat produced by the aluminium smelting process. In addition there is the presence, in the environment, of an exceptionally high amount of dust and solid particulates, due to the use of a thick layer of alumina with its thermal insulation function, which covers the smelting tanks like a sand bed.

Further criticalities are determined, on the one hand by the many chemical substances that are released into the environment and that, when bound with the oil or humidity in the air, are particularly corrosive, and on the other, by the presence of an outstandingly high magnetic field which alters the operation of each electronic apparatus.

In this context, where even maintenance becomes problematic, the compressors must be able to ensure continuous operations, without any interruptions.

Mattei M135 series compressors, suitably adapted and sized, have proven their outstanding reliability and durability in recent years, with performance levels that meet all demands.

In particular, over the years, the Mattei R&D division has been able to gain significant experience, which has led to it adopting some special set-ups.

To overcome the temperature problem, for example, both the oil circuit and the cooling system, i.e. the radiator and fan are dimensioned appropriately, where the blades are made of aluminium to be protected from the dust and sand. Even the electrical components – in particular the copper components of the motors and the magnetic sheets – are over-dimensioned in order to withstand the high temperatures.

The motor casings also undergo a special coating process to prevent the formation and the accumulation of condensate and stainless steel and aluminium are used, in place of other alloys which are particularly subject to corrosion.

Finally, particular attention is paid to the filtration of the incoming air, due to the profuse presence of alumina powder in the environment. Mattei uses a two-stage filtration system, the first being the dynamic type – to intercept and exhaust the heaviest and most contaminated part of the air flow, – the second being the physical type, with filters once again over-dimensioned. Finally all the electronic control systems are remoted in an acclimatised area.

Who is Mattei

Ing. Enea Mattei S.p.A. designs, manufactures and sells rotary vane compressors on a worldwide scale. This exclusive and distinctive technology has made it one of the authorities in the market segment of compressed air. Every year, the company manufactures more than 6,500 rotary vane compressors, exporting more than 70 percent of its production.

Mattei is based in Vimodrone, in the province of Milan, and has two plants in Vimodrone and Verdello-Zingonia (Bergamo). It has subsidiaries in France, Germany, Great Britain and the USA; representative offices in Russia and Spain, and numerous commercial partners throughout the rest of the world.

Founded in 1919, Mattei is still a family-owned company today. www.matteigroup.com