Servomech innovates current applications with the performance of the new series of ball screw jacks. This evolution meets the new needs of the designers and the applications.

The ability to innovate and be ahead of the times is a constant feature for Servomech, since 1989 the international reference player in the design and manufacturing of linear actuators, acme and ball screw, ball screw jacks, acme screw jacks, bevel gearboxes and ball screws and nuts. Made in Italy, flexibility, customization, design and internal production with systematic controls during the whole production processes, with technical support are just some of the advantages of the company based in Bologna – ITALY that has been able to gain a leading role worldwide with more than thirty years of activity. The use of the Servomech product allows for other important advantages, often requested by the market: for example immediate cost reduction thanks to an efficient optimization of product and performance, lower energy consumption, greater load capacity of the same size, improved rigidity of the structure, reliability and top quality service.

A new concept in lifting systems

Considering an advanced industrial context, where more and more frequently the need for high speeds and continuous operations, as well as load and positioning control, the designers evaluate with great interest solutions with higher performances, easier to control (position, load and speed), and able to guarantee a competitive advantage in terms of quality and quantity of the work performed.

Based on this evolution, Servomech promotes a new concept in lifting systems, with an innovative approach, focused on the application of its high-performance ball screw jacks, with brushless motors and related drives and controls. Customers and designers are free to choose the brand of motors and drives they prefer.

The next generation of lifting systems proposed by Servomech allow you to reach high linear speeds, high dynamic operations with relevant acceleration and deceleration, high positioning accuracy, exact position repeatability and operations with a continuous duty cycle. The synchronism between the various lifting points is carried out in the electrical axis, with the control in position or in both position and torque. The use of ball screw jacks equipped with servomotors, absolute multiturn encoders and drives capable of managing the motion capability of the motors and the control of the required current, allow for reaching high speed, precision and repeatability performance.

The traditional lifting systems are in low linear speed applications, with intermittent operating cycles, preferably with the use of acme screw jacks. Through different configurations depending on the needs and dimensions and through the mechanical connections with connecting shafts, mechanical couplings and motion transmission reducers, the screw jack with motor transmits the movement to the other lifting points through a mechanical synchronism. This solution has some limits, mostly related to linear and rotation speed, inertia masses involved and the lost power in the various transmission components, vibrations, noise and play that can be created between the mechanical connections, and the uncertain accuracy of the positioning of the various lifting points.

The new generation of lifting systems proposed by Servomech therefore broadens the application horizons of lifting systems in general with a modern and advanced approach. Lifting systems can now be used for continuous operations, for process functions, with also heavy load working cycles, with highly dynamic conditions, high speed, high accuracy and control.

The advantages of the new series of ball screw jacks

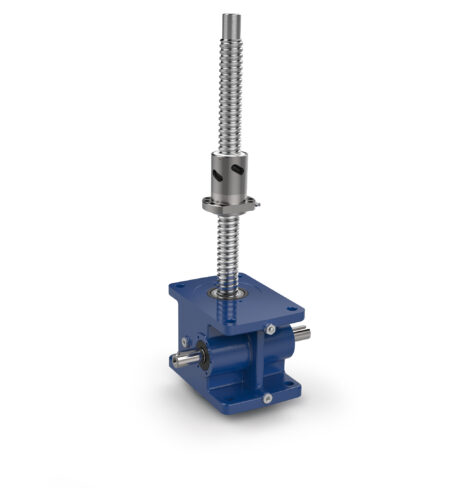

Greater performance in terms of efficiency, load capacity, durability and rigidity. These are the values and the advantages that the Servomech MA BS Model A Series ball screw jacks with travelling screw guarantee to the market, thanks to an innovative patented design that after a decade still proves to be innovative, establishing itself on the market for uniqueness and competitiveness.

The native integration of the gearbox components and the ball screw nut, designed and produced inside the Servomech factory, ensure, together with the advanced design, a significant weight reduction, eliminating superfluous material to the advantage of costs. The result is not only superior performance and greater positioning accuracy, but also greater rigidity with compact dimensions. Thus exceeding in performance the application limits of the more traditional acme screw jacks.

Available in 8 different sizes, load capacity from 5 to 350 kN, ball screw diameter from 16 to 120 mm, input speed up to 3.000 rpm, oil lubricated gearbox, continuous duty cycle. Together with the travelling screw Model A execution, Servomech also provides the travelling nut with rotating screw execution Model B. Three different families of products, each designed and developed with unique characteristics and with a wide range of sizes, equally distributed in order to have an optimal selection from both technical and economical point of view.

SJ BS Series is made for intermittent duty cycle applications (up to 70%). The gearbox monobloc housing is truly robust and compact. The gearbox is long life lubricated with synthetic grease. Input speed up to 1500 rpm, ball screw from Ø 16 mm a Ø 140 mm, load capacity from 5 kN to 800 kN. Available in 11 different standard sizes at catalogue.

To extend the applications opportunities with ball screw jacks, Servomech also provide the HS Series, acronym for High Speed. Transmission with bevel gearbox with Gleason spiral toothing system to allow low noise functioning and high efficiency. Recommended for continuous operation and high linear speeds. Input speed up to 3000 rpm makes them suitable for use with brushless motors. Bevel gearbox lubrication is long life with synthetic oil. Available in 6 different standard sizes in the catalogue, load capacity from 10 kN to 200 kN, ball screw from Ø 25 mm to Ø 80 mm, linear speed up to 2 m/s.