After years of in-depth studies and accurate experimentations, they presented a performing and innovative valve to the market, suitable for bottling very heterogeneous products: still, gaseous and sparkling in ideal way, with total control on the entire process.

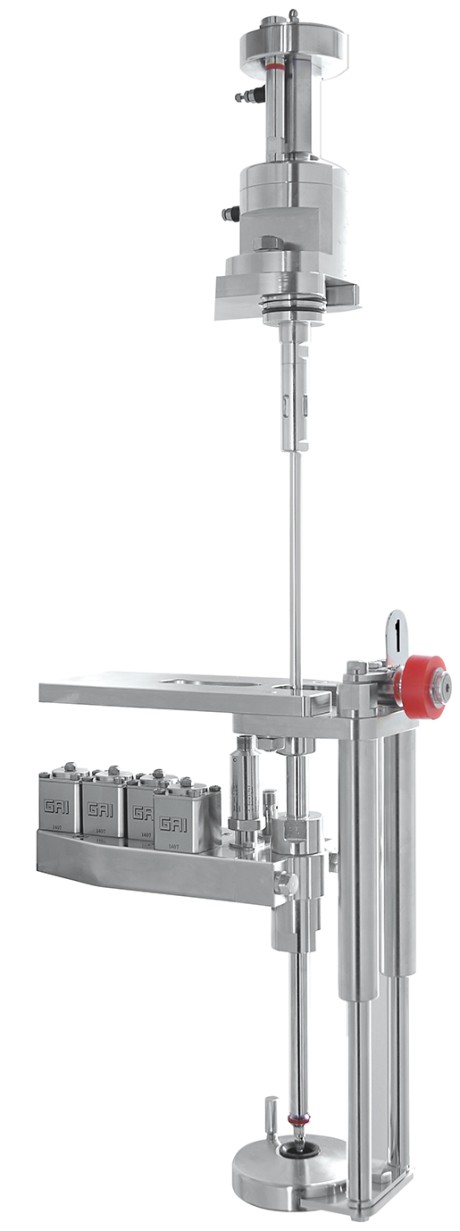

Detailed view of Gai 5032 RE HP monoblock.

For almost seventy years now, the Italian company Gai has been designing and manufacturing machines for high-quality alimentary products and it is one of the few in the world able to develop both filling and packaging solutions, carrying out all the functions included in the bottling process. With over 80% of the lines destined abroad, the company performs its activities in the manufacturing unit at Ceresole d’Alba (CN), in a factory taking up 40,000 covered square metres, designed and organized for the complete cycle, from design to the receipt of raw materials, from production to assembly and up to the departure of machines, tested and ready for the commissioning. A context in which research & development and experimentation result in solutions able to satisfy the most different market requirements. Part of this strong bent for innovation is also a new patented electro-pneumatic valve, which allows choosing the ideal bottling conditions according to the type of selected product, without any manual intervention of the operator.

Process quality, without compromise

«It is a patented system – specifies Davide Demarchi, production manager of Gai Spa – ideal for filling both still wines and sparkling liquids, without any compromise in working phase, whose development took two years of intense research and experimentation».

The valve allows working with a pressure from a minimum of 0 to a maximum of 8 bars, for filling levels that can range from 25 to 100 mm and setting all parameters on the control panel. The auto-levelling device permits precision with 0.5 mm tolerance. Precision, the latter, assured by the closing of the filling and return gas tube, when the required filling height is nearly reached.

Due to its devising, design and implementation, the valve allows shifting from one product type to the other in the simplest and quickest way. The bottling will turn out ideal, minimizing the oxidation degree and attaining the highest guarantee of sterile bottling.

«A special dummy bottle – adds Demarchi – it too protected by a specific patent, assures effective sanitization and sterilization flows with a fully automatic process».

The electro-pneumatically actuated valves, coupled with the presence of dummy bottles with discharge circuit, allow creating well-defined and then fully effective sterilizing cycles. The process improves the sterilization quality, besides ensuring it is securely carried out on any circuit on the filler. We can easily guess that machines are linked to an automatic CIP system and the sterilizing cycle is carried out in unmanned modality, thus improving the plant production timing.

«Notable advantages– adds Demarchi – are detectable in degassing, too, where the gas return is regulated to prevent the product pollution and to reduce oxidation drastically».

Highest operational flexibility

The fillers equipped with this innovative and patented valve are therefore highly flexible for the typology of heterogeneous products for which they can be intended: High Pressure electro-pneumatic fillers (max. working pressure 8 bars); Low pressure electro-pneumatic fillers (max. working pressure 1 bar); Bier electro-pneumatic fillers, specific for beer. In short, 3 versions of electro-pneumatic valve. In particular, the one called 42000 E LP (with light pressure), compared to the 42000 E HP version, misses the degassing circuit, proving to be highly suitable for still or slightly sparkling products (max 1 g CO2/litre). Advantages of this valve, in comparison with standard gravity or light vacuum (or isobaric) valves, is the flexible operation, since all working parameters (vacuum in bottle, working pressure and filling level) are set on the control panel and can be modified without any manual intervention of the operator; this, as already said, granting the slightest oxidation degree and the highest warrantee of sterile bottling.

«It would not have been possible – states and ends Demarchi – to obtain the same performances, the high flexibility and quality of the requested product with valves already available on the market. Operational peculiarities, the latter, that now allow us to release a version to conquer market segments with not so high production demands but, instead, with a researched and prestigious quality of involved products».

Made-in-Italy excellence for three generations

When, astride the fifties, the founder Giacomo Gai and his wife Elsa manufactured their first bottling machines, the word “wine” had not the values it expresses today. The course of the Italian oenological excellence started at that time. Gai explored and travelled it together with his customers, often anticipating solutions. Already in 1979, he invented the monoblock: the idea of joining all bottling functions in a single machine has become the standard for the entire sector. Over the years, the range has extended from still wines to sparkling ones, from beer to wines in PET and others, performing all process phases “from the liquid to the finished bottle”. A productivity grown from 3,000 bottes/hour to virtually unlimited quantities; numbers attainable with modular machines, to be combined through flexible and customized projects, also for very big productions, based on absolute quality. Quality today managed and controlled also by the third generation, nowadays operating by full title in business management roles: Giacomo, son of Battista and Adriana, in the accounting management, and Guglielmo and Giovanni, sons of Carlo and Renata, entrusted with the industrial and sale management.