Since 1976 Pneumax Spa has been one of the primary manufacturers of components and systems for the compressed air automation. A status gained on the field thanks to the internationalization course undertaken and to the solid leadership represented by the Italian market. Now Pneumax plays three aces, by presenting three new product to complete its portfolio.

Headquartered at Lurano (Bergamo, Italy), Pneumax Spa presents numerous state-of-the-art products for the automation of machines and systems in pneumatics. Among them, it is worth highlighting by presenting three new three implementations that integrate a sound and proven catalogue.

The new proportional regulator with connector M12 was implemented by Pneumax in three sizes with 7, 1,100 and 4,000 NI/min flow rates.

Airplus size 4

The new series for the air treatment Airplus represents the evolution of the by now well-tested series 1700. According to Pneumax targets, it is devised and developed according to flexibility and easy and fast installation criteria, paying particular attention to the performance improvement and to the introduction of state-of-art technical solutions. Cups, made of transparent polycarbonate (PC), are equipped with anti-collision protection as standard, assembled to the body with a fast bayonet-type coupling system and equipped with safety button. The filter, available with three filtering stages (5 µm, 20 µm and 50 µm) is provided with a condensate draining tap, prearranged for the manual or semi-automatic operation. The automatic draining is available upon demand. The regulator makes use of a low-hysteresis rolling membrane, the system is balanced and can be equipped with integrated manometer. Four regulation stages are available from 0 up to 12 bars and the regulation knob can be locked in position by pressure. The oil quantity regulation occurs by acting on the adjustment needle positioned on the small transparent polycarbonate dome where the coolant flow is easily visible and controllable. The oil suction pipe is equipped with sintered filter as standard to avoid that possible impurities contained in the oil are introduced into the downstream circuit. The progressive starter allows the gradual pressurization of the plant thus avoiding pressure peaks sometimes damaging for downstream devices. The filling time of the downstream circuit is adjustable by means of integrated flow rate regulator and the full flow rate operation is attained at the achievement of about 50% of the input pressure. The pressure switch intake, which can be calibrated from 2 to 10 bars, and the air intake finally complete the available elements.

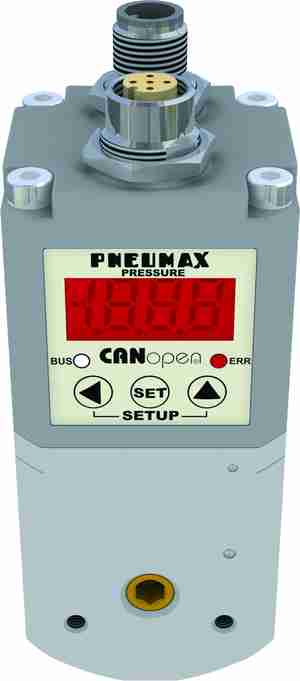

New series of proportional pressure regulators

An electronic-control proportional regulator, able to vary the pressure value in time, implemented by Pneumax in three sizes with 7, 1,100 and 4,000 NI/min flow rates. This, instead, the solution to satisfy the need of current industrial applications that ask pneumatic cylinders to intervene on parameters that must be dynamically modified during the machine operation. A step forward compared to standard solutions, which exploit the pneumatic logics coupled with valves fed at different pressures, often involving excessive overall dimensions. The application fields of proportional regulators are all those where it is necessary to check dynamically the force of an actuator or the pressure variation, like, for instance, closing systems or packaging machines.

Regulator filter with digital pressure switch

The regulator filter with digital pressure switch is equipped with membrane pressure regulator filter with relieving function, low-hysteresis rolling membrane. It features a balanced system and double filtering action: by air centrifugation and by filtering element. The filtering element made of HDPE (high density polyethylene) is available with 3 filtering stages (5 µm, 20 µm and 50 µm), it can be replaced and regenerated by washing. The polycarbonate (PC) transparent cup with anti-collision protection as standard. The cup assembly is performed with bayonet-type fast coupling and safety pushbutton.

The semiautomatic condensate draining is mounted as standard or it can be automatic upon demand. Four pressure regulation stages are available, up to 12 bars. Finally, the knob locking by means of pressure is possible when the desired value of P2 (regulated pressure) is achieved. It is equipped with ring for panel mounting, with digital pressure switch as standard.

Our force? Investing in people

Interview with the Sales Manager Italy and Mediterranean area Andrea Carluccio.

Mr Carluccio, what are the peculiar characteristics of Pneumax?

Over the years, the company has developed an organizational model based on the enhancement and empowerment of people, in full respect of their rights and dignity. According to this vision, the company has recently adopted the Ethical Code as guideline and reference model for the daily activity of all managers and collaborators. Those principles are mirrored in the everyday work of owners, single line operators and management, aimed at the development of the company’s products, then of the made in Italy, through a new way of conceiving the enterprise and its role in the local and global scenario.

How can you summarize your mission?

In few words, to bring out the made in Italy worldwide. Pneumax tries to do that daily, meeting the world market requirements with thee concrete approaches: high performances of the implemented products and technical-applicative flexibility; customized pre- and after sale service; internationalization and brand presence all over the world. This one, defined P2B that is to say “Pneumax to business”, is for us a model that should represent the only solution to make the Italy System recover from the serious crisis affecting it from the distant, but still very topical, 2009.

How can you define P2B?

The idea of the P2B consists in defining modalities, processes and competences to transmit the same business image to the market worldwide, acting on people’s behaviour and method and on the organization capability of facing the competitive context where it operates daily. The P2B model is composed by some initiatives, all of them aimed at the progressive culture development and the Brand defence through an internal and external communication strategy, a new sale approach, the product innovation and the dialogue with the market. The pillars of P2B are: market orientation, product innovation and appurtenance sense.

What do you deem as your main upholding points?

Research and development are the main driver of innovation and allow us to interpret customers’ needs, implementing the most cutting-edge products through state-of-art design and prototyping systems. Moreover, an efficient logistics couples the material availability with the capability of offering assembling, wiring and testing services of machine parts and systems, thus becoming integral part of customer companies’ productive chain. Finally, the capability of proposing and repeating solutions everywhere thanks to a network that speaks the same language and can then generate a competitive advantage through a glocal approach, in other words local solutions globally available in the world.

How does the Research and Development sector operate?

The Department organization relies on all necessary resources to accomplish all the phases of new product creation in full autonomy, no matter whether they are intended for a range enlargement or they are specifically designed for determinate sectors, applications and customers. We have also our in-house electronics department, to be able to manage proprietary solutions and integration systems with clear performance and technological advantages, to satisfy the market requirements in fast, autonomous and competitive way, with a sale organization consisting of 25 technical-commercial sites in Italy and 60 in the world, if we consider branches and concessionaries. All markets are important for us, each with its own opportunities and potentialities.