Due to their design features, pneumo-hydraulic control units join standard pneumatic and electric actuators.

The pneumo-hydraulic control units currently proposed by Bonesi Pneumatik represent the technological evolution of the patent registered by Generalmeccanica Company in Milan in the Seventies, developed with the aim of combining the advantages of pneumatic cylinders’ user-friendliness with the possibility of precise motion control assured by an integrated hydraulic circuit, housed inside the unit itself. By using pneumo-hydraulic control units, it is possible to accomplish the functions of fast approach to the workpiece, a fine regulation during the work phase and the quick return with hydraulic deceleration. All functions, better described hereunder, can be obtained for both the forward and return piston rod.

Characteristics

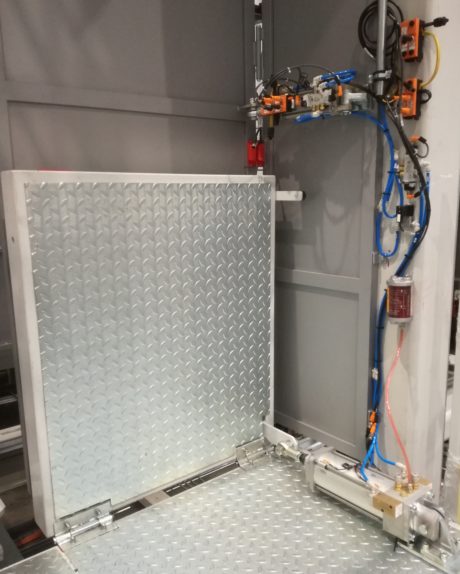

The design features of this product represent the summary of two applied techniques: compressed air as driving power and hydraulic system as fluid control. The combination of these two technologies allows operating these actuators with the simplicity of a standard pneumatic cylinder but with possible precise motion control assured by the hydraulic system, without needing bulky and expensive outer control units. Pneumo-hydraulic control units, constituted by a pneumatic cylinder with a hydraulic circuit integrated inside the piston rod, permit a precise speed regulation and a simple, sturdy and reliable motion control. The actuators proposed by Bonesi Pneumatik are made up by a double-acting pneumatic cylinder with a closed circuit coaxially integrated for the oil recirculation, housed inside the piston rod. The piston rod of the unit, with increased diameter compared with the one of a standard pneumatic cylinder, is made with a high-strength steel tube, chrome-plated outside. Inside the piston rod, the use of two tubes with inferior differentiated sections allow obtaining two hermetically sealed chambers, containing the oil of the hydraulic circuit. Owing to the motion of the pneumatic piston, controlled by normal five-way directional solenoid valves, the oil contained in the circuit is subjected to circulation between the two chambers and is made flow through the control group, positioned on board of the cylinder or externally, with the aid of hydraulic tubes. The piston rod motion speed, in the forward and/or return stroke, can be regulated precisely and uniformly by the insertion of one or two unidirectional flow governors. It is possible to reach approximate minimum speeds of 0.5 mm/s, anyway maintaining a smooth constant motion, irrespective of workload variations and the feeding pressure of the pneumatic circuit.

End-stroke hydraulic decelerators

Besides, units can be equipped with end-stroke hydraulic decelerators, which allow an optimal absorption of the kinetic energy, coaxial as to the motion. By inserting oil interception valves in the control group, it is possible to obtain skip and stop functions for both the forward and the return stroke of the piston rod. Valves are available with pneumatic or electro-pneumatic piloting, in normally closed or normally open version. The stop function is very useful to assure an immediate and safe motion stop in case of emergency or stop need, even multiple stops and in several positions, with possible precision of 0.1 mm. Each unit is equipped with oil tank, necessary to compensate the volume difference between the two chambers during the circulation. The tank can be directly mounted on the control unit (on board) or assembled apart and connected by flexible pipes (remote). As just said, the system allows then achieving numerous functions on both work strokes: adjusted and constant speeds when workloads and feeding pressure change. After years of activity, in the course of 2002, the owners of Generalmeccanica Company changed and the latter was merged by Bonesi Pneumatik, with headquarters and production plant in Legnano (Milan, Italy). Bonesi Pneumatik has then become owner of the brand and of the designs for the production of pneumo-hydraulic units, which for several years have been protected by various patents.

Applications in industry

The first sector that exploited the advantages offered by pneumo-hydraulic units is the industry of woodworking machines. In fact, to control the tool motion during drilling, milling, tenoning and mortasing operations, the leader manufacturers of heartwood working machines have fruitfully adopted Generalmeccanica units. Afterwards, also the manufacturers of cutting machines for aluminium, wood and PVC profiles have found in pneumo-hydraulic units the optimal solution for the control of the cutting blade motion. The functions of fast approach to the workpiece, fine regulation for the cutting phase and quick return with hydraulic deceleration are efficaciously performed for this type of applications. Since then, the manufacturers of machines and equipment in the most various industrial sectors have adopted pneumo-hydraulic units in their automations, like for instance: machines for ophthalmic lens processing, due to the precise positioning of the workhead; rereeling machines and cutters for plastic films, for the control of the film tension on tensioning rolls; automated polishing lines, for the controlled motion of brushes; forming of brass taps, for the motion control of the cutting riser carriage of the rough part just formed; rotogravure printing machines, for the motion control of printing cylinder- holder carriages; marble and granite working machines, for the precise control of the sheet polishing spindle motion. In each of the applications where they have been used, pneumo-hydraulic units have assured high sturdiness and reliability qualities, even in the most challenging environments.

More recently, this type of actuators has proven its high usefulness also in the sector of papermaking and tissue paper converting sector, in all those applications of coil lifting or driving of tensioning and pressing arms, where a standard pneumatic cylinder cannot control the motion efficaciously. A use example is the application of pneumo-hydraulic units, with diameter of 100 mm and stroke of 200 mm, exploited for the footboard lifting. The use of this unit allows a precise control of the footboard ascent and descent motion and an emergency stop in any point of the stroke through a lock of the inner hydraulic circuit, impossible operation with a standard pneumatic cylinder. Another application example is the pneumo-hydraulic unit, with diameter of 100 mm and stroke of 250 mm, used in an assembling station for automotive industry’s components. Through the control assured by the integrated hydraulic circuit, this unit allows a precise keying of the fan on the electric motor shaft.

The range of pneumo-hydraulic units by Bonesi Pneumatik

In the course of 2017, to upgrade the product technically and aesthetically, Bonesi Pneumatik developed a range of pneumo-hydraulic units in compliance with the ISO 15552 regulation. In the ambit of this restyling, the main issues at which the technical division of Bonesi Pneumatik worked for the implementation of the new range were the performance improvement, the optimization of the hydraulic circuit operation, the design upgrade with the use of extruded aluminium profiles that integrate the slots for the insertion of magnetic sensors or of a position transducer and the integration of the control group oil tank.