Camozzi Automation and Camozzi Digital: a winning partnership for IIoT solutions and Cyber-Physical systems for industry 4.0

The winning partnership between the leader of the Camozzi Group, Camozzi Automation and Camozzi Digital: together they show their combined solutions for Industry 4.0.

Specialists in the production of components, systems and technologies for the industrial automation sector, Camozzi Automation’s solutions are used to control fluids (liquids and gases), with particular application across the transportation and Life Science industries. Its partner, Camozzi Digital is the ultimate System Integrator of application solutions for Industry 4.0.

The two Divisions announce together Camozzi’s latest Cyber-Physical systems for predictive maintenance in smart manufacturing and their new intelligent components for IIoT.

Special end-to-end Cyber-Physical systems

More in detail, Camozzi’s special end-to-end Cyber-Physical systems integrate sensors and intelligent components that are able to transmit complex process data to management systems and the cloud, through an IIoT Gateway supplied by Advantech.The information gathered can be analysed in real time by means of sophisticated proprietary algorithms and processed to produce detailed diagnostic reports, from which customers can generate predictive maintenance plans for their machines, increasing efficiencies and reducing costs.

An array of ‘smart’ components

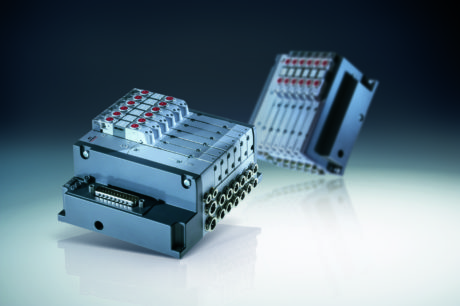

Camozzi also launches an array of ‘smart’ components: the Series D valve island and the Series PRE proportional pressure regulator, equipped with CoilVision technology.

More specifically, the Series D was developed to meet the growing demand from the market for an advanced solution able to guarantee high quality standards while offering maximum flexbility. A key feature of the Series D is its ability to combine two different valve sizes in the same island bringing important benefits in terms of reduced dimensions and costs, with the help of only one initial electric part. Another characteristic of the Series D is itsCoilVision technology that constantly monitors the operational parameters of the solenoid. In fact this diagnostics system provides, through a web platform with a graphic interface, an overview of, for example, the on/off state of each valve, the number of cycles, the level of power consumption and any possible overheating in the coil.

The Series PRE proportional pressure regulator, with CoilVision technology has been similarly designed to constantly monitor the operation of the solenoids and prevent any possible malfunction. Also in this case, the data collected are transmitted to the cloud in an aggregated way and can be made easliy available to the customer through a dashboard. The Series PRE is available in two sizes and in a number of different configurations, among which is an IO-Link connection. Lastly, a version with external sensor connections is available for applications that require monitoring the pressure of aggressive liquids or gases.

Pneumatic cylinders in compliance with standard ISO 6432

Another innovative product is the new Series 23 pneumatic cylinder. In compliance with standard ISO 6432, these cylinders incorporate‘auto-cushioning’* technology, that guarantees optimal deceleration, for a smooth, jolt-free movement of the cylinder which reducesboth vibration and noise, resulting in a product with improved reliability and consistant performance over time.

*Patent pending

The opinion of the experts

«We are proud to present this new range of cutting-edge systems and solutions dedicated to Industry 4.0, a result of our consolidated expertise and our approach that is oriented towards continuous innovation», says Lodovico Camozzi, President and Chief Executive Officer of the Camozzi Group, and adds «Our commitment is reflected in the many parnterships made with prestigeous Research institutes and Universities, that have led to the creation of these new solutions ».

Marco Camozzi, Managing Director of Camozzi Automation says «The interconnection and digitisation of productionprocesses are the main challenges of Industry 4.0. Today more than ever, companies worldwide need to meet this challenge, to increase their competitiveness. Camozzi’s innovative components and smart systems will allow companies to continuously monitor the performance of their production processes, plan maintenance activities more effectively and efficiently and significantly reduce downtime and operating costs.»