Parker’s frameless spindle servo motors become a crucial part of new MultiSwiss CNC lathes.

Swiss-type CNC lathes are becoming increasingly popular with metal part manufacturers. They have evolved from simple screw machines to high-precision, high-production machines now widely used across many industries to completely machine small parts, even for complex operations where no turning is required.

One of the biggest challenges for metal part manufacturers is increasing productivity. Motion control specialist Parker Hannifin has demonstrated how its advanced permanent magnet synchronous servo motors can play an important part in reducing the amount of space needed to position components and cutting tools in the next-generation design of Swiss-type lathes.

Tornos SA is a market leader in sliding headstock technology and manufactures ‘Swiss-style’ CNC automatic turning machines, computer-aided and numerically-controlled multi-spindle machines and machining centres. They specialise in machines designed to produce high quality parts with extreme precision.

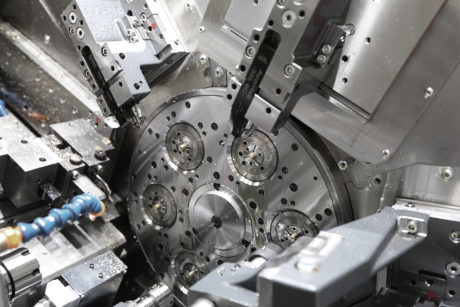

The MultiSwiss 8×26, the latest version of Tornos’ next-generation MultiSwiss machines, is equipped with eight independent spindles and eight slides for main operations. Housing up to three tools per slide, the MutliSwiss can produce turned parts at previously unachievable levels of productivity.

Space and maintenance saving

In its search to find the best synchronous motor technology for the MultiSwiss 8×26, Tornos selected the SKW series of frameless spindle servo motors from Parker. Made up of two separate elements (rotor and stator), the motors are integrated directly into the machine’s mechanical structure.

Compact, reliable and highly dynamic, the SKW series motors offered Tornos constant torque capabilities over a wide speed range with very small dimensions. The space-saving design gave Tornos the flexibility to fit eight spindles into the MultiSwiss without sacrificing any of the high-precision benefits that come with permanent magnet synchronous motors.

Among the major benefits are reliability and almost zero maintenance due to the direct drive motors’ lack of mechanical parts. Other advantages include very high stiffness and positional accuracy, quieter performance and overall robustness.

A long-standing design win

Parker’s partnership with Tornos has existed since 2005 when it first supplied its SKW series motors for the Tornos MultiAlpha 8×20 and MultiSigma 8×24 multi-spindle machines. Tornos depends on Parker for its extensive engineering support as well as the company’s high performance components.

«Parker has always responded to our technical specifications and our expectations when it comes to the performance we require. Parker has outstanding experience and skills when it comes to synchronous motor applications» said Bertrand Faivre, Engineering Manager R&D. «We were glad we could benefit from that, and we used Parker’s leading technology for our machine design as well as focusing on increasing productivity. With the high-performance output of Tornos’ machines in mind, the quality and reliability of Parker’s solutions made the collaboration a good fit. Parker supplied Tornos with a complete, tailored solution, including a cooling system and sensor equipment.»

«We appreciate the close cooperation with Parker, in terms of both commercial and technical aspects. We also benefit from Parker’s strong commitment with regard to after-sales support and enjoy the close contact and cooperation with Parker’s research and development department», said Faivre. «Over time, this has meant Parker has turned out to be not only a reliable supplier but also a trustworthy partner.»

Learn more at www.parker.com or @parkerhannifin