While the condition-based maintenance uses the detection of failures of machines and equipment to plan their maintenance, the cyclic one tends to carry out some preventive interventions long before the probable malfunction. In both cases, there is the possibility of maintaining machines in operation with evident cost savings.

Luca Melideo

Preventive programmed maintenance

The operation of whatever plant, for instance an oilrig, a refinery or a chemical plant…, implies the management of a broad range of machinery and equipment that unfortunately do not go on working forever. To maintain machines and equipment in perfect efficiency, it is necessary to carry out maintenance interventions at regular intervals and, in most cases, the progression of malfunctions will be initially high because assembly defects emerge in the early phases: a long period of regular work will follow, with some malfunctions now and then, afterwards the effects of wear and tiring will significantly increase the likelihood of failures and accidents. The level of machinery reliability is generally expressed as the mean time between malfunctions. The traditional technique consists in carrying out maintenance interventions planned long before a probable breakdown. The very elementary principle says that if the machine is overhauled with more frequency, replacing the components in bad conditions, the failure will be avoided. Unfortunately, things are not so simple: machines break down anyway, because components do not last how long it is licit to expect, on the other hand other components may last longer than what foreseen.

We can summarize the main drawbacks of the maintenance planned at fixed intervals, and called “cyclic”, as follows:

- By its nature, it is a very cautious approach and this leads to a redundant maintenance with higher costs;

- For the same reason, operation times of lines and plants decrease;

- Disassembling a machine that was working satisfactorily might cause new problems;

- Components break down anyway, because several malfunction modalities have a constant probability, i.e. they might occur at any time, with the unpredictable machine stop and the consequent need of urgent maintenance intervention;

- The cyclic maintenance cost is very high in terms of production stop (loss of turnover) and of direct costs (work, materials and logistics…).

To overcome these troubles, many industries have assessed the more proactive and less intrusive approach according to which the plant maintenance is carried out according to the effective machine conditions: the so-called condition-based maintenance.

Condition-based maintenance

The central principle of the condition-based maintenance is that the initial deterioration phase of a machine can be detected through the monitoring and the assessment of the trends of various parameters, in other words the condition monitoring. Afterwards, once identified a potential problem, it is possible to plan in advance some maintenance interventions, so minimizing the impact on the plant availability. Depending on the seriousness of the failure in evolution, interventions can initially include a more frequent monitoring, and then follow their deterioration, choosing the scheduling of either future interventions or the immediate machine stop, with the eventual activation of back-up units. The main advantages of the condition-based maintenance, in comparison with conventional cyclic maintenance practices at fixed dates, are the possibility of detecting at once unforeseen malfunctions through the condition monitoring, and the consequent possibility of planning the necessary interventions to prevent machine breakdowns. This provides important economic advantages it is worth highlighting:

- The reduction of unplanned downtimes increases the overall plant availability: for instance, a preventive stop on an oilrig generally costs two thousand Euros a day, therefore it is essential to reduce drastically the cases and downtime times of some critical machines;

- The reduction of indirect damages, with the consequent drop of machine repair costs. To make a typical example, if the total cost (material and labour) of the bearing replacement in a pump amounts to 5,000 €, the bearing failure when the pump is in operation might lead to the collision of the impeller against the volute, with a bigger damage and a pump replacement cost of 45,000€: in this case, the condition monitoring would allow a neat saving of 40,000€;

- The elimination of many interventions previously programmed, leaving only mandatory ones, to be executed in conformity with law provisions, and those that concern the malfunction modalities the condition monitoring cannot face. On balance, the elimination of superfluous maintenance interventions on an oilrig results in a yearly cost saving of around 200,000 €;

- The condition monitoring allows an approach based on the risk assessment and provides the possibility of managing the exposure to identified risks proactively:

- Maintenance interventions can be planned and optimized, possibly as part of a “maintenance campaign”: in other words, they can be carried out when convenient;

- The activity can focus on the solution of specific problems already known and this optimizes the use of labour, spare parts and logistics;

- The other programmed interventions can be sometimes delayed in presence of satisfactory machine conditions;

- Finally, maintenance costs are notably decreased.

As we have seen, the condition monitoring is the fundamental activity to acquire the necessary information on which to base interventions. However, one of the main requisites to take the appropriate maintenance decisions according to real conditions is the presence of measurable parameters, providing indications about the machine health, with the value alteration that clearly warns about the presence of a potential breakdown. Through the monitoring and the processing of the trends of these parameters, the conditions of the machines and of their components can be “followed” to determine the presence of acceptable, critical or alarm conditions. The condition monitoring is based on parameters that indicate the machine conditions and of which it is possible to process the trend consistently, to highlight their evolution.

The possible parameters are many but we are describing here just the three most used, that is to say:

- Vibrations

- Temperature

- Lubrication

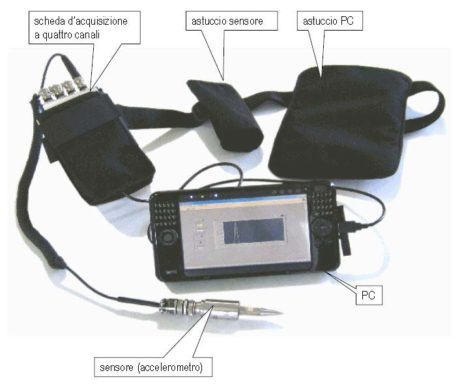

Vibrations

In a machine, vibrations are generated by small unbalances or by alternative stresses while in operation. These vibrations are generally measured by installing some accelerometers on the machine body or by motion probes arranged on bearings. Machine malfunctions can increase the levels of already existing vibrations or cause new vibrations in other components, which can be detected by the appropriate vibration probes. If vibration levels are ignored the result can be a catastrophic machine breakdown: for this reason, in critical machines the probes that measure the overall vibration level are often connected with an automated system of machine stop or protection. Tracing an overall trend of vibrations in a certain lapse of time, it is possible to detect machine failures in early phases and plan the most adequate maintenance interventions before serious damages occur. The overall vibration level can provide and approximate indication of machine conditions. Nevertheless, often it is not precise enough to give a clear warning on certain troubles and it does not offer a sufficient diagnostic information, apart from the position of the increased machine vibrations. Actually, vibrations are linked with the operation conditions of rotary machines, such as the shaft speed, combustion frequency in cylinders, meshing frequency in transmissions, temporary frequencies of a fan or a pump blade. In rolling bearings, a series of high-frequency impacts is often visible during the first malfunction phases. These frequencies depend on the bearing geometry and on its rotation speed. For malfunction detection and diagnostic purposes, it is highly opportune to identify vibration levels at these specific frequencies. The majority of the instruments for the vibration data collection provide signal process capacities, which transform the rough signal into a spectrum graph showing the vibration levels at each frequency. Different malfunctions will have different spectra and the correct interpretation is the result of the fine skills and experience of the technicians who take care of the diagnosis. Today systems able to provide precise phenomena interpretations are available on trade. Generally speaking, simple trends of the overall vibration level can indicate some kinds of failure in evolution.

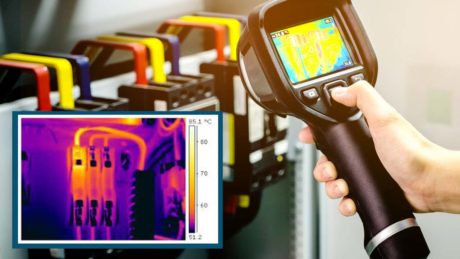

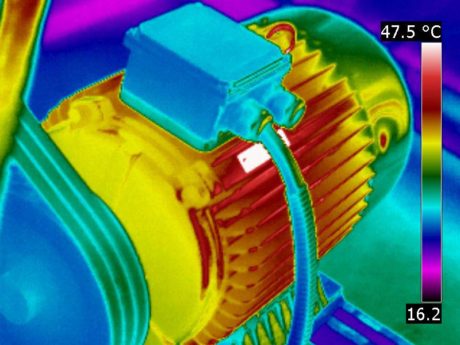

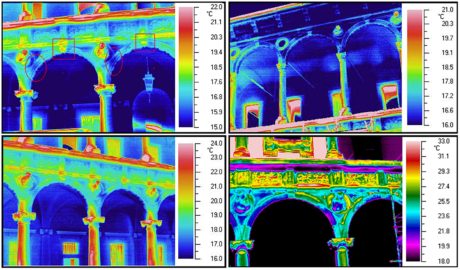

Temperature monitoring

Besides increasing vibration levels, the mechanical failures of rotary machines often influence the load on bearings, with the possible temperature rise in the adjacent area. For this reason, turbines, pumps and compressors of big sizes are often equipped with fixed temperature probes to monitor temperatures on bearings. These probes are often connected with a machine protection system. Therefore, the temperature of bearings is a valid condition-monitoring instrument: if temperature probes are not fixed directly on bearings, they can be suitably installed for monitoring the temperatures of the return oil. In case of smaller-size machines, often without temperature probes, it is possible to monitor the surface temperature of bearings through an infrared-ray thermometer or with more refined, but already quite cheap, systems of thermal image processing, the so-called thermal cameras. For some machines and equipment, especially based on combustion, the temperature distribution is in its turn a useful parameter. For this reason, it is customary to monitor the average, minimum and maximum temperature around the burners of the gas turbine; an irregular distribution can indicate problems in the burner or encrustations in the stator blade.

Lubricating oil analysis

The analysis of lubricant samples allows determining two important factors:

- The oil quality and the appropriateness of the required functions;

- The identification of wear particles and other contaminants connected with wear.

The detailed study of these contaminants can provide an insight of their origins and of the wear speed. Oil samples are generally analysed by specialized laboratories able to provide detailed information on the oil properties and on the contaminants in suspension. There are three types of analyses:

- Fluid properties: viscosity, density, acidity, corrosive potential, additive concentration, dielectric properties;

- contamination: analysis of humidity and water content, flammability point and quantification of particles;

- wear particles: density of particles, analytic ferrography, spectrometric element analysis.

Depending on the application, one or more parameters can indicate the initial phase of a malfunction. The joint processing of a certain number of parameters can be useful for the identification of a specific problem.

Conclusions

The condition-based maintenance can reduce maintenance costs, due to the possibility of delaying maintenance interventions, going on producing. The condition-monitoring activity consists in the measurement, processing of trends and analysis, through the use of parameters that indicate the initial phase of a malfunction, to take appropriate and timely maintenance decisions. The condition-monitoring activity naturally involves some costs for the hardware purchase, for the necessary time for the data collection and analysis and for the specialized software for predictive and trend-processing functions. To be more efficacious, it is indispensable to optimize the choice of parameters, of monitoring intervals and of systems, implementing the solutions that provide the best detection performances, obviously supported by efficient corporate processes.