Megadyne celebrates its 60 years of history, with an expansion its product range to anticipate new application demands and to reinforce Megadynes market positioning.

The new products presented by Megadyne for several applications are:

– Megalinear Quiet Self Track, polyurethane self-tracking, silent running timing belts;

– Megalinear GW, thermoplastic polyurethane belt for heavy applications;

– Silver2, a new generation high capacity timing belt;

– RPP Steel, EPDM open end rubber belts with steel cords;

– Conveyor Belt Food quality, to meet the most stringent standards.

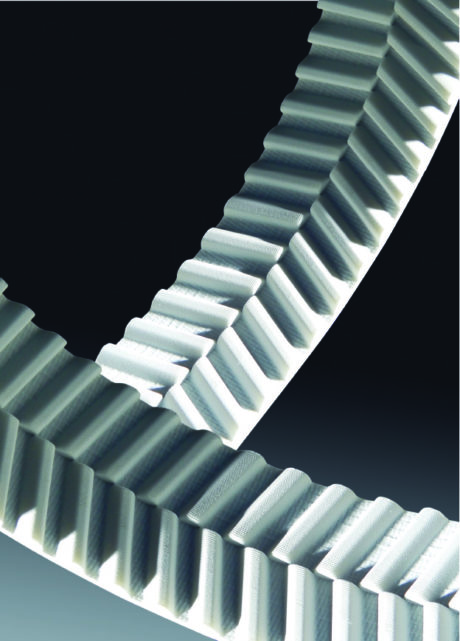

Megalinear Quiet Self Track (QST)

Specifically designed and manufactured, to reduce the noise level generated during high speed operation The Megalinear QST tooth configuration consists of a left and right helix, which maintains

the belt in the centre of the QST pulley, eliminating any belt wander and ensuring high precision linear positioning. The precise and continuous mesh between the belt and pulley delivers a significant reduction in noise levels, versus a traditional type of trapezoidal or curvilinear tooth design. Additionally, as the Megalinear QST is completely self-tracking, there is no need for flanges on the pulleys. The nylon faced helical offset teeth provide a high torque capacity.

Megalinear GW

For heavy applications, Megadyne introduce the Megalinear GW, a high performance thermoplastic polyurethane belt. Superior load capacities can be achieved, due to the high shear strength of

the tooth design, coupled with high tension, steel zinc coated cords. Megalinear GW guarantees a greater transmittable power under continuous high loads. Megalinear GW is rated at a +30 % higher breaking strength in comparison with similar belt types and is especially resistant, to rapid changes in acceleration. Ideal for high load stop/start applications (e.g. automatic storage and retrieval systems, lifting, handling, and vehicle body transport).

RPP Steel

RPP Steel is a new open ended rubber timing belt, manufactured using an innovative process. The RPP Steel reinforcement is provided by multi stranded, high-strength / modulus steel cords of “S” and “Z” twist. Vulcanised within an EPDM body, forming a single homogenous product. This production technique enhances the tensile strength and makes the belt resistant to flex fatigue forces, whilst the “S” and “Z” cords afford optimum tracking properties. Additionally, this belt withstands chemically aggressive environments (ozone and UVA) and an extended range of working temperatures (-25°C/+80°C).

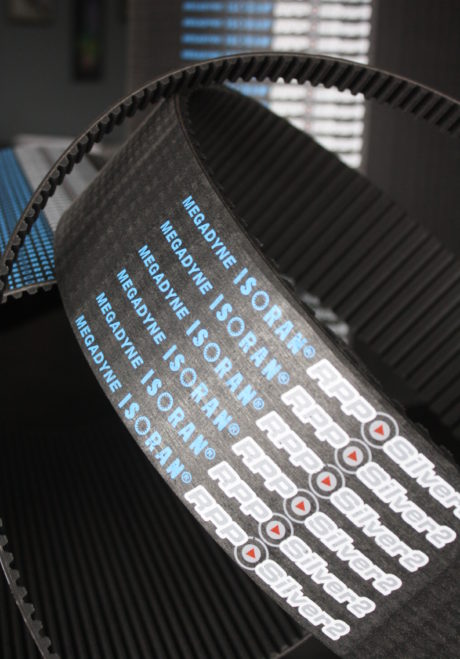

Silver2

Retaining the RPP tooth profile of the existing Silver, the new Silver2 enables full functional interchangeability with other deep profile systems. Current RPP or Silver types can be upgraded without pulley replacement. With increased tooth shear resistance, Silver2 has a compact design that can optimise space and cost for new drive systems.