By Vuototecnica, technologies 4.0 for the vacuum management

The Italian market of Industry 4.0, after a gratifying 2020, despite the difficult social and health situation, scores an important growth. The Observatory Transition Industry 4.0 of the School of Management of the Politecnico di Milano, communicates that in 2020 the growth amounted to 8%, with a value worth 4.1 billions. In 2021, they instead estimate a final growth ranging from 12% to 15%, with a value of 4.5 billions.

The primary driving engine is represented by the cloud manufacturing (about +30%), followed by the investments in the automation field and in the implementation of new man-machine interfaces (around +25%). Vuototecnica attentively follows this trend of industry 4.0 and is part of it under all respects, investing together with the producers of industrial automation in the research of forefront solutions for the vacuum gripping and the vacuum creation on various types of plants.

Vacuum gripping systems

Established in the Seventies and today ranking among the leaders in the technologies to create and to manage vacuum, the company headquartered at Beverate di Brivio (Lecco, Italy) has always staked on the research and design of products studied according to buyers’ requirements. The Vacuum Solutions catalogue contains over 900 pages of solutions created in over 40 years of activity side by side with customers. It is subdivided into 11 sections: vacuum cups, vacuum cup holders, vacuum measurement, control and adjustment instruments, vacuum valves and solenoid valves, suction filters, vacuum fittings and hoses, vacuum pumps and pumpsets, vacuum generators and pneumatic pumpsets, Octopus vacuum gripping systems, graphic division and special products.

New touchscreen panels

The company has recently focused on the design of intuitive efficient man-machine interfaces, which can favour a more controlled and more sustainable work environment for operators and higher operational efficacy. These first forays into digital have given birth, for instance, to the new operator panels with touchscreen. They combine a tablet-screen and a digitizer, and they are provided with a very broad visual angle, enabling the machine state control at any time, they represent a valid aid for operators who now have at disposal a page with the vacuum trend in real time, through graphic; specific alarms for each problem, through which it is easier to find eventual failures, periodical maintenance messages by the plant, in the most suitable time.

Moreover, they allow a remote control (optional) to keep the equipment’s values monitored also from remote. They are equipped with a highly intuitive 7”- 10” touchscreen with graphic interface, where it is possible to adjust the vacuum degree for the uses foreseen but also, if desired, to visualize Vuototecnica products through research with QR code and they support the choice of five languages.

New EGN valves

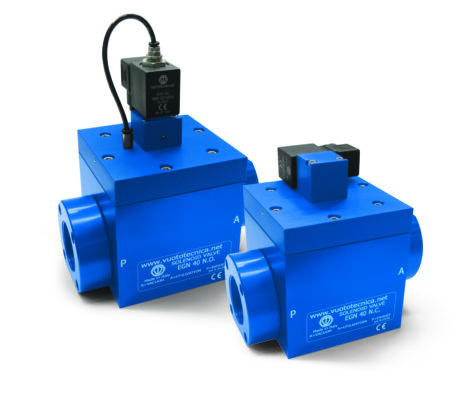

The catalogue is also enriched by a new EGN series of direct-operated 2-way solenoid valves, perfect for all applications where suction must be controlled separately from the air supply to the circuit, as it happens for instance for degassers, autoclaves and vacuum heat sealers. The body of these new valves is made from solid aluminium. A fundamental difference that makes them stand out from valves implemented by die-casting. It is a construction choice that ensures the total absence of micro-cracks of the valve body, often present in the production processes of die-cast bodies.

Moreover, this structural solution ensures that residual operating pressures of 0.5 mbars are reached and maintained. EGN valves operate on the pressure differential existing between the pump or vacuum generator and the pressure of the sucked air, and by conveying this “differential pressure” to the servocontrol, through the actuator, the shutter is controlled without the need for compressed air or springs. This guarantees a very high switching speed in favour of high working cycles in emptying systems. The actuation times of EGN Vuototecnica valves are half those of the most commonly used valves, generally ball valves pneumatically actuated, diffused in emptying processes. Which makes them perfect in fast emptying applications, for instance in vacuum packaging processes.

The future

Vuototecnica will go on staking on innovation, through research, in conformity with the most demanded parameters: efficiency, flexibility, energy saving and attention to green energy. For all products, both the most recent ones and those dating back to the far past. The search for new markets and new technologies will always remain the company’s priorities, with the awareness it is as important to strengthen more and more the satisfaction and the efficiency of those already existing.

Vuototecnica has already undertaken a publication course of its whole CAD library on Traceparts: a community with over 3.5 million registered users (mainly technical offices) that are accustomed to searching for and downloading from this site CAD libraries in native format, compatible with one’s own CAD. Today transmitting knowledge is fundamental to make customers more aware of research possibilities in the field and to support them in more and more efficient manner; moreover, it allows establishing a common ground of growth and of prospects for the future, which was unimaginable in the past. Furthermore, on corporate sites it is possible to surf the technical specifications of each Vuototecnica component, to contact designers for the customization and to see product videos and applications.