How can we choose and design the complete ideal screw jack or lifting system for your application simply and quickly? The solution comes from Zimm.

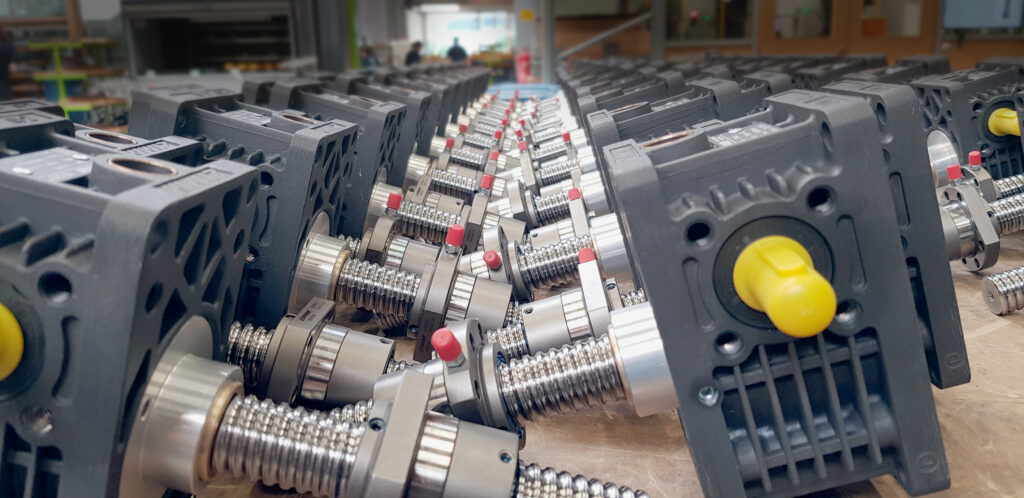

Reference supplier on a global scale in the field of mechanical screw jacks, Zimm can supply solutions to displace loads that can reach even a weight of 100 tons. A wide diversified product range, subdivided into 14 sizes from 2.5 kN to 1,000 kN, trapezoidal or ball screws, motors, couplings and much more, to facilitate a suitable choice for respective applications.

To further simplify their selection, the company has in-house devised and developed a performing on-line product configurator that allows designers to choose screw-jacks and to configure their lifting systems in user-friendly, fast and, especially, step-by-step guided manner.

Compared to the most diffused selectors and/or CAD platforms at disposal on the market, this configurator represents an ideal tool able to provide in few seconds, in fully automated manner, not only all information concerning screw jacks but also those about accessories; the most extreme included, and especially in terms of applicability, like for instance electrically-controlled safety nut screws, self-aligning nuts or all accessories to configure an oscillating axis.

From the single screw jack to the complete system

Upon free registration to the service, the engineer can benefit from the configurator and from all its functional potentialities, directly entering from his own browser with his own login and password.

From the home page, it is possible to choose between the two configuration opportunities: single screw jack/complete system of screw jacks; separate accessories (including asynchronous motors, shafts and couplings).

In both cases, through quick guided procedures, it is possible to input the few necessary data for the definition of the elements that make up the project, without running into possible errors. The configurator is in fact designed in such a way as not to need any programming knowledge, but also to carry out continuously a conformity control in background. This means that if the designer makes incompatible and/or not admissible choices, he immediately receives a notification communicating that this combination is not possible and the field is marked in red, explaining the reason.

Four steps

More in detail, for instance for the configuration of a single-screw screw jack, the 4 steps to be accomplished are the following:

- You choose the type, the size and the version of the screw jack, specifying its stroke.

- You configure the accessories (terminal, bellows, stroke end and so on). As alternative, it is also possible to decide inputting the necessary parameters for the product definition. Therefore, you can select one of the three series of Zimm screw jacks (series ZE, series Z and series GSZ), to choose the size, the typology of trapezoidal or ball screw, the stroke, the load direction and how you intend to install it.

- Once ended the procedure (which does not change in case of selection of the complete system or of the accessories), through a specific pushbutton it is possible to visualize a preview, a 3D preview of the same and to choose the preferred format in 2D or 3D with which receiving designs (the most common CAD 3D formats are available, besides the diffused DWG 2D format and the PDF 3D to obtain an immediate visualization).

Thanks to this peculiarity, we can visualize everything quickly and simply on any PC, even without the presence of an installed CAD software.

- Selecting “Request CAD”, in few seconds you receive an e-mail containing not only the designs to be implemented in your own project, but also an accurate description of technical features, and of performances, in combination with the order codes of what selected, to demand eventually for an offer afterwards.

Zimm: lifting with precision

Broad and diversified, Zimm product range allows satisfying the most different requirements.

The series of ZE screw jacks, the standard for Zimm, is already characterized by some innovations that allow achieving very high efficiencies, great positioning precision and linear speeds that were unconceivable in the past for mechanical screw jacks.

The high-precision ZE H series goes beyond, accepting input speeds of 3,000 rpm, it can be operated by brushless motors and have an even higher use factor.

All 14 sizes of ZIMM screw jacks, from 2.5 to 1,000 kN, are made of corrosion-resistant materials, have manifold installation modalities and are indifferently equipped with trapezoidal or ball screws of relevant size, too, up to Ø 160.

In combination with bevel gearboxes, connection shafts and joints, all in-house manufactured by Zimm and all available in the configurator, make the company one of the leader manufacturers of lifting systems in the world.

(by Gianandrea Mazzola)