R+W, a leading German multinational designer and manufacturer of precision couplings and transmission components for industry, has developed new lines of couplings with integrated sensors to help factories evolve towards the 4.0 model.

Since their debut on the components market, AIC (Artificial Intelligence Coupling) couplings with integrated sensors have attracted considerable interest: the ability to measure quantities relevant to process efficiency directly in the transmission is a novelty that brings unquestionable advantages to designers and production companies. But how did the project which led to these couplings start and evxolve? We asked Sascha Markert, who developed the product at R+W.

When did you first understand that the market needed a coupling with integrated sensing systems? Did you receive an explicit request from customers or was it an intuition on your part?

The first time R+W had a vision about measuring torque inside a coupling came as early as 2008. It turned out be too early because the energy efficient wireless communication systems were not available at that time. There has always been an indirect demand from the market for miniaturization of machinery to save energy. We figured that if we could integrate torque and speed measurement into our couplings we could save weight, screw connections and support bearings.

When did you start designing the new coupling? Could you briefly describe the phases, from design to prototype, testing and production, providing a timeline?

At the beginning of 2019 we did the first designs. Later that year we built the first prototypes for internal testing. In 2020 we shipped the first prototypes with a battery energy source for field testing to test speed and torque measurement and the soft- and hardware components. Due to the high demand of continuous testing we developed the prototype equipment for induction charging in the later half of 2020. The first projects using these prototypes started in the first quarter of 2021. After that a design freeze will happen to prepare for serial production.

Based on your previous new product launch experience, how would you describe the birth of AIC? Was it particularly demanding in terms of resources and time-to-market?

Looking back where we are coming from as a pure mechanical equipment manufacturer the toughest challenge was to introduce knowledge for hardware and software development which results in measurement equipment.

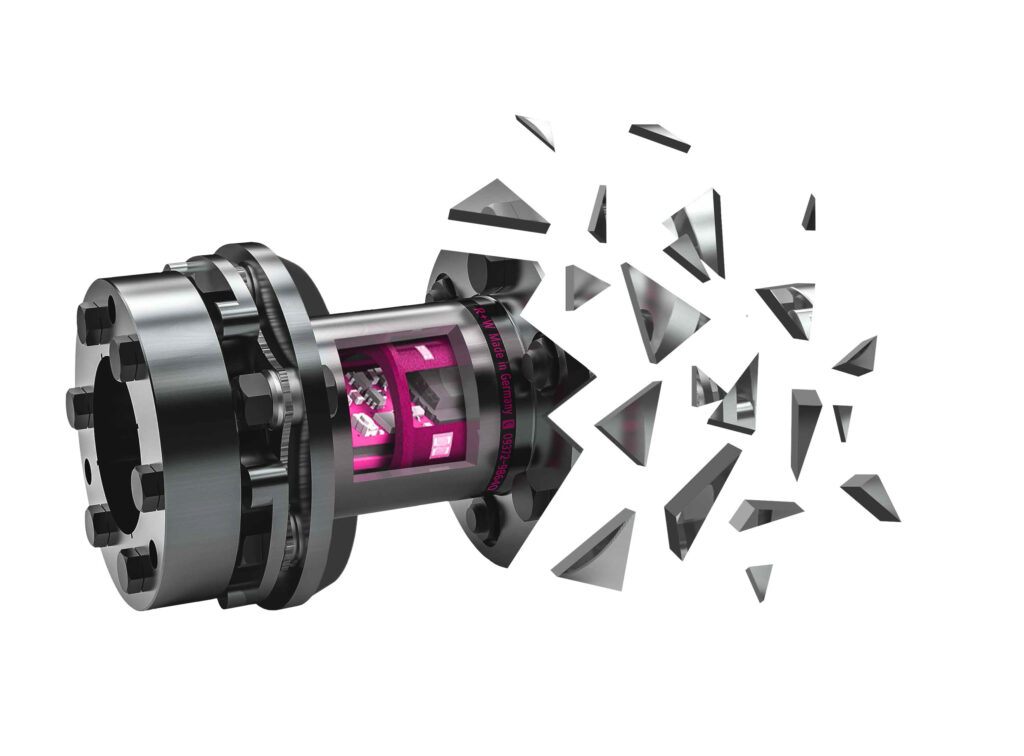

AIC technology can be integrated into any coupling, but which was the first type of coupling where you inserted sensors? Was there a specific reason for this choice?

The very first sensor coupling was a line shaft ZAE type. Since the ZAE line shaft has an aluminium tube between the elastic elements it was clear for us that this was the easiest one to start with.

Is there a dedicated production line for AIC couplings or are they being manufactured using the same lines which produce the non-AIC versions of the couplings?

In the early stages we are using the non-AIC production line but if there is an increase in sales we may want to switch to a dedicated production line.

What were the reactions of the first customers you approached with this technology? Was there any difficulty in convincing them to accept this new paradigm?

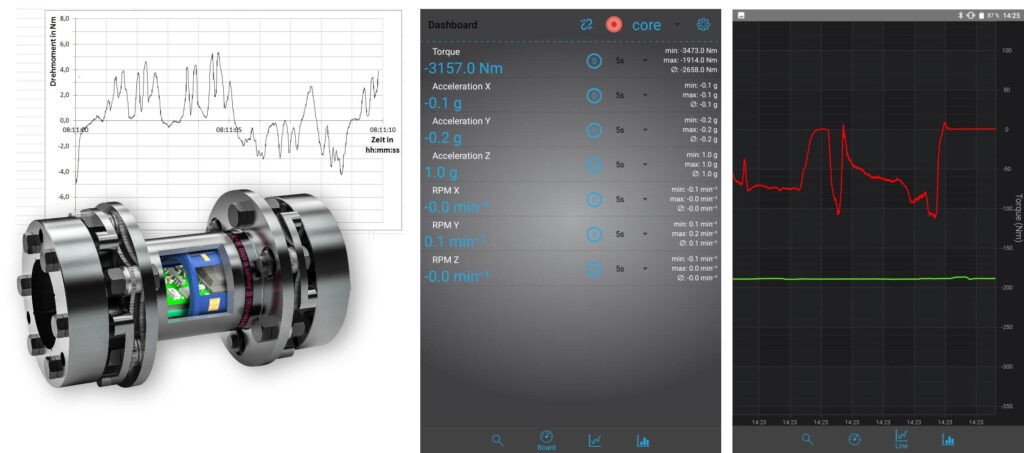

Nearly all of our customers were happy that we were bold enough to try out something new. The reason is that the coupling business is very slow to adapt to new technologies. To be able to use tablets and smartphones to read live data from the coupling became instantaneously our customers’ favourite development. Now the biggest task for us is to convince the customer that our product is reliable in the day-to-day business.

AIC couplings are very new, but what percentage of the couplings you manufacture and sell will be AIC in the foreseeable future? Which types of coupling do you think will be most in demand in their AIC versions?

From what we see right now the line shafts were a good choice to start with. Also the disc couplings with steel spacer and integrated sensor equipment seems to fit the customer’s needs. Backwards compatibility is a very convenient opportunity to replace existing line shafts with AIC line shafts to retrieve data from existing machinery in cases where the customer never had the opportunity to retrieve data at all. It’s quite convenient for customers that they don’t have to change existing equipment. Another example is to change hubs (different bore sizes) and keep the AIC tube spacer. It gives the customer the flexibility to collect data from different machines with one AIC tube spacer. The modularity of our couplings gives the customer a lot of flexibility to use the AIC coupling in a cost effective way.

Do you envisage creating informative elements or, when this will be possible, organizing live training sessions to help customers exploit the full potential of AIC couplings, or do you think its advantages are entirely self-explanatory?

Due to the design freeze and field tests we are conducting this year we will gather relevant data and application examples. From that we will start creating training material. As the AIC coupling has been designed in a way that it is easy to use we also want to make sure the training material is easy to understand.

What industries are showing, or have already shown, most interest in AC couplings? Could you mention examples of successful introduction of these couplings in production processes and/or suggest which applications will be realized in the near future?

Back-to-back gear test rigs seem to be the perfect candidates for our AIC couplings. We will replace existing torque transducers which rely on bearings and bearing supports t are positioned between two separate couplings. Our AIC coupling fits in as a lean solution.

One of our customers is building extruder machines where only a coupling is installed. He knows how much power is going into the machine but does not know what happens in the extruder channel. He wants to replace the existing coupling with a torque limiter attached to a disc coupling with AIC technology. Then he will have the possibility to observe the extruder behaviour over time to obtain a better understanding of the process.

R+W is always ready to provide more information on AIC intelligent couplings, to listen and understand the needs of its customers, to offer non-binding, real-time advice to identify the ideal coupling for each project and to respond very quickly to requests for quotations.