If we refer to product innovation and evolution, Servomech Group constantly releases interesting novelties on the market. Among them, a complete range of linear servo-actuators and electromechanical cylinders that, due to their characteristics of efficiency, performances and precision, represent a convenient solution to the problems concerning the use of hydraulic and pneumatic cylinders.

Product innovation, know-how, competences and total control of the entire manufacturing cycle (fully in-house accomplished), make Servomech Group a national and international reference partner in the implementation of solutions for the linear motion, in particular in the production of linear electromechanical actuators, ball screw jacks, ball screws and nuts. Servomech has introduced several novelties into its production range, remarkably widening the line of existing products and especially releasing more advanced and complex mechatronic systems to meet the new applicative market requirements.

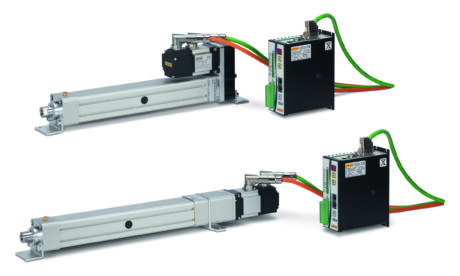

SA electromechanical servo-actuators: the future of linear applications

The new range of electromechanical servo-actuators by Linearmech, division of Servomech Group dedicated to automation and mechatronics, represents a real innovation for the customary users of pneumatic cylinders that need to manufacture increasingly fast, precise and compact machines, reducing energy consumptions and controlling all axes in centralized way.

Linearmech servo-actuators Series SA have a fully modular structure and are available in different structural typologies to allow their utmost use flexibility. The only mechanical linear unit can be easily interfaced with the servo-motors of the main brands on trade. Besides, it is available a complete servomotor package, still produced in-house by Servomech, with in-line or parallel assembly. Characterized by sturdy and compact structure, these servo-actuators adopt fully innovative solutions, ranking in the high-end segment of automation components. All internal parts have been purposely studied and designed to operate under conditions of high work dynamics: high linear speeds, low inertia of components, extreme positioning precision and repeatability, reliability and long life in time.

Seven are the different standard sizes at disposal, with linear speeds up to 1,500 mm/s and maximum peak forces of 4,200 daN. All servo-actuators are provided with ball screws in-house manufactured by Servomech (different precision classes are available depending on specific applicative requirements) and with a wide range of fixing elements according to the ISO 15552 standard of pneumatic cylinders, for a total and simple interchangeability with the existing pneumatic cylinders.

Servomech is the only manufacturer of linear actuators relying on its own in-house production of all components, ball screws and nuts included. Thanks to this unique competitive advantage, Linearmech linear servo-actuators are the future of linear applications, a real, advantageous and innovative alternative to conventional pneumatic cylinders.

High-performance electromechanical cylinders

If we speak of product innovation and evolution, Servomech Group constantly releases interesting novelties on the market. Among them, a complete range of electromechanical cylinders that currently, due to their characteristics of efficiency, performances and precision, already represents a convenient solution to the problems concerning the use of hydraulic cylinders.

Due to their design and implementation, the new Servomech electromechanical cylinders are more efficient products with lower energy consumptions. This result was achieved thanks to the attainment of higher efficiency, aspect that allows installing lower powers and consuming energy during the operation only. Another distinguishing peculiarity is the higher control of position/speed/force, i.e. the possibility of performing high speeds and loads under the precise and accurate position control. Among the main strongholds, worth signalling also the positioning precision in the order of hundredth of mm, the very high repeatability, constant in time, besides better safety and reliability: there are no risks caused by the high pressures and no oil leaks. Moreover, it is possible to receive the exact documented calculation of the service life of components. Servomech cylinders are available in various assembling configurations, for a total interchangeability with the existing hydraulic cylinders. These new solutions assure also lower installation and maintenance costs and they can be implemented in special executions, designed according to customers’ specific requirements. Finally, since only the cables for the power supply and the signal transmission are necessary, also connections are simpler and, certainly not negligible aspect, long periods of inactivity and missing maintenance can go by without affecting their readiness for use.

Five Good Reasons for choosing electric

More efficiency with low energy consumptions, better control of position, speed and force, exact position repeatability, higher safety and reliability, lower installation and maintenance costs. These the main arguments of the campaign “Five good reasons for choosing electric”, to prefer Servomech electromechanical solution instead of standard hydraulic or pneumatic systems.

The challenge in the era of Industry 4.0 consists in rethinking the manufacturing with solutions and machines allowing companies to suit promptly the fluctuating demand of the market. Today machine and plant manufacturers constantly pursue more productivity, higher efficiency and better output while decreasing costs. Therefore, the use of innovative products featuring these characteristics increases the machinery value and shares in differentiating one’s own product in the scenario of the global competition. In the ambit of the campaign “Five Good Reasons for Choosing Electric”, Servomech groups its state-of-the-art products, developed to meet these new market needs.

All Servomech products are fully designed and manufactured inside the company’s productive plants at Anzola dell’Emilia (Bologna), where today about one hundred workers are employed. To support the productive development of its products and not only, last September Servomech Group inaugurated a third building that takes up 5,200 square metres, exclusively intended for production, in an area close to the existing headquarters. Today the manufacturing area of Servomech can rely on a total covered surface of 14,000 square metres.