Productivity, quality and process repeatability are the essential requisites of Banbury Mixers for tyre manufacturers. Challenging requisites, which can be reached only through algorithms conceived for the control of hydraulic axes with force limitation.

The most important machine of the rubber processing process for the tyre production is the mixer, better known as Banbury Mixer. This machine is equipped with a pair of rotors, which mix polymeric materials under very precise temperature and pressure conditions. The pressing system is equipped with pneumatic cylinder, more commonly called RAM, which directly acts in the mixing chamber to control the mixture volume and the compression force.

The rubber mixing cycle needs a very precise force control, to manufacture a mixture that has the correct physical characteristics to satisfy the performance requirements of the state-of-the-art tyres. To obtain a homogeneous mixture with specific features, the process repeatability is essential, especially during the transitions between the hydraulic control of force and of RAM cylinder position. The dynamics and the accuracy of these sophisticated algorithms allow shortening mixing times and managing the different mixtures at best, with a consequent general increment of the quality of the rubber processing process.

Electrohydraulic solutions for Banbury mixers: the formula by Atos

Atos can boast a long successful expertise in the development of complete solutions for electrohydraulic systems for the control of mixers.

Atos solution has been developed with the target of minimizng machine downtimes through advanced diagnostics combined with the proven reliability of Atos valves, fruit of years of research and expertise gained on the field.

The commitment of Research and Development engineers of Atos is satisfying the more and more exacting demands of rubber technologists, optimizing the dynamics of the proprietary hydraulic logics of the force control.

The technology of digital drivers allows refining the development of force and position control, gaining access to the chronology of alarms and carrying out acquisitions through the integrated oscilloscope. Since all these functions can be managed from remote, Atos technicians have successfully executed the development and the commissioning from remote of complex mixing systems, notably decreasing commissioning times and costs.

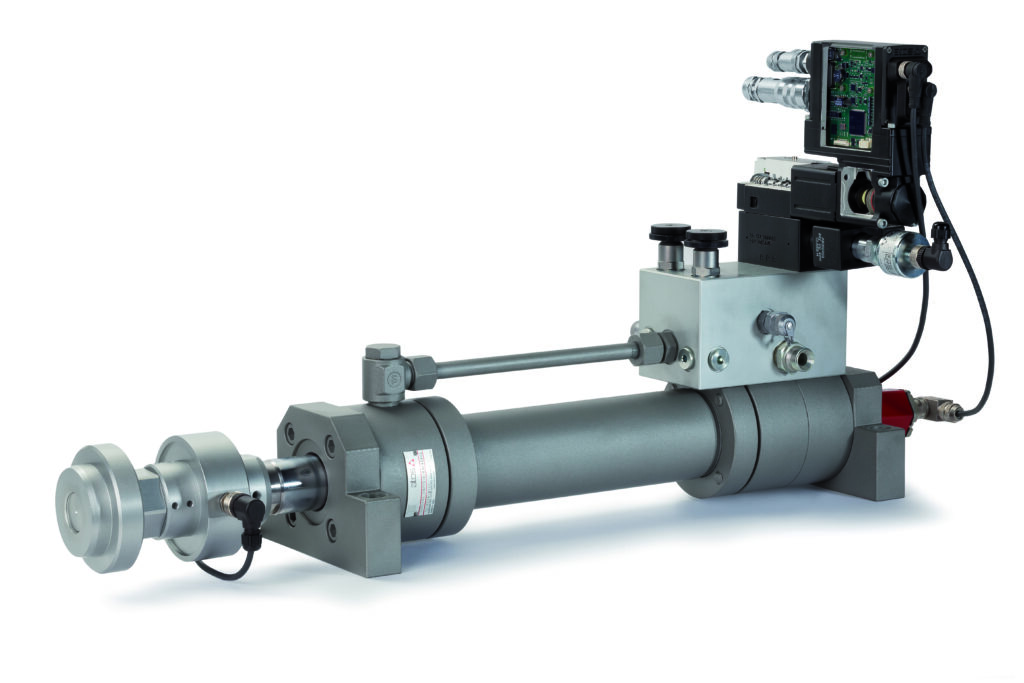

Atos is the reference partner of tailored electro-hydraulic solutions for Banbury Mixers, as it relies on a complete range of servo-proportional valves, safety valves and a tried and tested system monitoring logic, able to satisfy the tyre manufacturers’ requirements all over the world.

Contacts

Are you interested in hydraulic systems of force control, axis control or pQ control by Atos? Do not hesitate to contact Atos