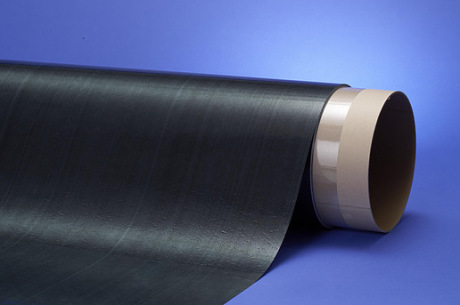

Toho Tenax Co., Ltd. developed a new prepreg (a carbon-fiber sheet pre-impregnated with matrix resin) that offers super-high-heat and -oxidation resistance suited to aircraft and automotive engine compartments. The new bismaleimide resin-impregnated prepreg does not reach glass-transition below 320°C, the result of Toho Tenax’s original resin-formulation technology.

Toho Tenax Co., Ltd. developed a new prepreg (a carbon-fiber sheet pre-impregnated with matrix resin) that offers super-high-heat and -oxidation resistance suited to aircraft and automotive engine compartments. The new bismaleimide resin-impregnated prepreg does not reach glass-transition below 320°C, the result of Toho Tenax’s original resin-formulation technology.

The new prepeg also maintains oxidation resistance without heat cracks under continuous use in the upper 200°C range. Toho Tenax plans to explore opportunities for aircraft and other fields, including sports equipment, with this new prepeg due to its formability at low pressure of around 0.5 MPa (70 psi). A flame-resistant feature now under development is expected to further expand applications to consumer electronics and other general applications. The materials supplier also intends to develop CFRP technologies for structural parts. Material development for first and second structural members of aircrafts and frame of automobiles are in progress. Learn more: http://articles.sae.org/13742/