Sheet metal stamping for the automotive sector and household appliance industries, together with design, manufacture and maintenance of tools are Bora’s sphere of specialization. Thanks to a co-design service, the company can collaborate and supports its customers in the whole production process: from the starting idea to its development and optimization, until the final creation.

The use of virtual prototyping techniques allows competing and standing out in a market turning out to be increasingly dynamic and fast.

The analysis of the stamping process through the finite element simulation allows assessing the relations among the various geometrical parameters of tool equipment and the necessary magnitudes to estimate the project validity; without implementing the numerous physical prototypes that would be necessary to succeed in defining correctly a method assuring the geometrical and dimensional tolerances demanded by customers.

This characteristic allows Bora, company headquartered at Moie di Maiolati Spontini (AN) that performs the activities of design, manufacturing and maintenance of tools (besides the sheet metal stamping of components for the automotive and household appliance industries), to offer a co-design service of the component together with final customers, thus reducing critical zones already in a preliminary phase; in addition to a drastic reduction of direct costs connected with the physical prototyping (design and implementation) and of the indirect costs linked with the testing phase.

Shaping the operations for perfect results

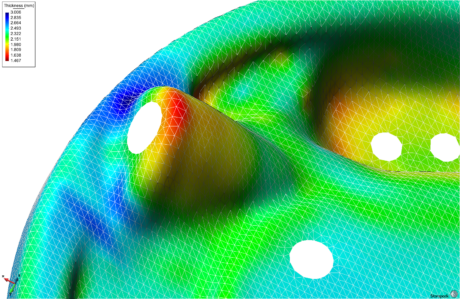

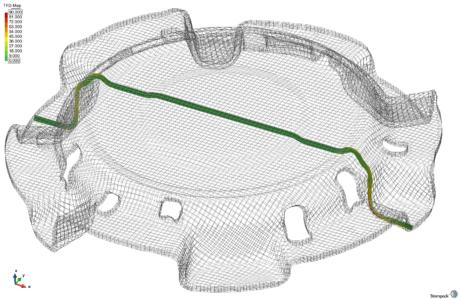

The main problems that generally emerge depend on the shape and on the characteristics of the piece to be implemented. In particular, for components characterized by small sizes compared to the thickness and by high deformation gradients, are critical the operations that affect the formability and the thickness reduction due to the deformation. Using finite-element virtual simulation techniques and relying on the long-term experience gained by the company in the sector, it is possible to model correctly roughing and forming operations, to propose possible modifications of the element shape to the customer. This to improve the feasibility and the attainable thicknesses in short times while providing highly reliable indications.

To the ends of a correct simulation of the stamping process, the company’s technical department manages both purely geometrical aspects (such as the shape of tools), and information about the material behaviour (by which are modelled the elastic response, the work hardening, the anisotropy and the formability diagram through the data provided by the supplier of raw materials), and dynamic aspects of the tool (such as the friction between the sheet metal and the various tools, the force and the position of the elastic members controlling the blank holders.