If a component is manufactured to make its user more competitive, also the customization requires know how for a tailor-made service for the user itself.

The industry 4.0 is like an immense and invisible force, which deviates the operational galaxy towards convenient strategies for all: suppliers and customers. With the fourth industrial revolution, clarity is convenient for all, provided that we are aware that “digital” alone does not represent innovation: man is always necessary because he makes the difference. In other words, the manufacturing industry must not be overwhelmed by innovation but must succeed in almost anticipating it. This is the true challenge, in a context where the transparent communication is protagonist.

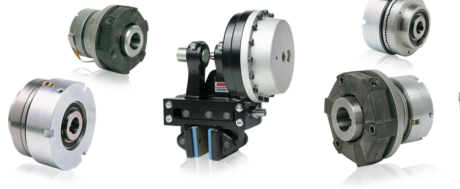

A challenge issued by MWM Freni e Frizioni Srl, producer of brakes, clutches, torque limiting couplings, one-piece assemblies and caliper brakes with electromagnetic, pneumatic, hydraulic and mechanical control.

Several decades of presence in the sector have allowed the Milanese company to attain notable results, both in standard implementations and in the applications purposely processed by its Technical Office to solve particular problems and to satisfy more or less complex requirements. Each product represents the synthesis between experience and the contribution of the most advanced design and control technologies. Studying customized components, even in one-piece batches, is the mirror of the constant technological evolution.

MWM Freni e Frizioni Srl excellently interfaces with the deep change that involves the production world today, providing for the deep integration of digital technologies into industrial manufacturing processes. At the base of this new manufacturing world, we can find a sort of technological disruption, characterized by the merging between real world of industrial plants and virtual world of the so-called Internet of Things. «Communication skills via Internet with customers require a sort of self- diagnostics, permitting the remote production control while the flexibility of systems allows customizing products according to the demand. The production chain of our components is reconstructed and simulated in a virtual environment, and afterwards tested, to solve upstream problems, to enable the personnel training and everything else. – explains Sergio Sartori, President of MWM – Today we work with the CAD, taking advantage of the Finite Element Method (FEM) to check the characteristics of our products in the context of their customization».

In the past, these tests were based on the customer’s experience or on the testing carried out by the customer itself or on internal tests under stress. Today, thanks to the digitalization/computerization, we can execute the same tests in fast and safe manner.

«FEM functions give us the possibility of controlling in the early phases resistances, the most suitable sizes, the loads to be applied, the stresses of the mechanical parts and much more» adds Sergio Sartori. It is not surprising, then, if MWM discovers, from time to time, always new problems and solves them, as in the case of a braking group for test benches of torque wrenches.

Sometimes customers themselves, after buying the component, turn to MWM for a specific adaptation; we are speaking of know how connected with the application, feather in the cap of the Milanese company that offers productivity and competence.

The matching of machine and component

MWM has made the right choice: a small company that has been keeping its know-how in the ambit of component users’ needs for several years and that avails itself of a customization-oriented strategy. It seems that this is one of the several trends of the fourth industrial revolution: customers order the component for their machines and all that they need for their activity, i.e. the all-round service; there is a certain union between the machine manufacturer and the component supplier.

Today digitalization enhances one’s own activity secrets and acts as interface with customers, to help them to understand the practical advantages and the economic returns of products and services offered. This evolution matters for MWM components too, dealing with machine manufacturers that intend absolutely to measure their competitiveness by signing customization contracts.

A component is conceived to live with the machine it is intended for, to improve it; well, this symbiosis between component and machine is the inspiring principle of MWM, which is upstream the component itself, whose shape lays on great technological contents and starts from the customer-supplier relationship.

«For fifteen years now we have been developing products tailor-made upon customers’ specific demands, according to the necessary technical specifications for the functions of the machine to be equipped. – underlines Mr Sartori. – It is a constant development, an all-round research. Requests are manifold indeed, application sectors endless because each industrial field is potentially our customer and therefore we are subjected to several potential unforeseen contingencies that, thanks to information technologies, are regularly annulled».

With design/production setting based on new technologies, it would be risky for the customer and for MWM to supply components in one/two units. We need accurate controls in engineering phase, new materials, new technologies mutually interfaced like 3D printing, Internet of Things, augmented reality, expert systems and so on, technologies that are changing the way of designing, implementing and distributing whatever product worldwide and can create a new “digital wire” in the entire industrial chain, which allows organizing and managing automatically big volumes of information. Target: assuring practical advantages and economic returns both to the supplier and to the customer.

Recently, MWM has supplied a braking group for the test benches of torque wrenches with particular characteristics; it is a special brake, customized, which must operate in a dynamic closing phase in order to permit a modular braking, perfectly linear from zero to the max. torque. Results are excellent indeed. They worked hard on all brake components, especially on carbon shoes and disks.

Beyond innovation

What does innovation mean for MWM? It means to manufacture components with always different characteristics but ameliorative in terms of function, sizes and added value because the machines they will equip perform increasingly fast and specific tasks and must suit in real time the evolutions of transmissions, kinematic gears and new materials. It is worth considering that in the industrial sector even two identical machines can be intended for two different functions, implementable with two different components. Componentry is determinant, especially when we speak of high-level machinery.

We transmit online three-dimensional designs, the customer integrates them into his project and then he decides the product purchase – ends Sergio Sartori.– Otherwise we carry out some modifications according to the customer’s requests, to supply a suitable product for his machine and his transmission, virtually compatible with his 3D design. Afterwards we shift from the virtual to the real and I can assess with satisfaction that finally concrete results almost always match with the virtual reality».

This means absolute integration with the new technologies, to move from the virtual to the physical product and then to the definitive test.

Therefore, Internet properly suits both consumer and capital goods and therefore components, too. MWM fully supports customers, which expect a real lean synchronization, that is to say the supply of products and services in full synchrony with requirements and in the required quantities: neither too little nor too much, neither soon nor late, wherever needed and at the lowest possible cost.

Nowadays 50% of the work is done in this way, which allows MWM to satisfy customized applications with utmost tranquillity. Everything is under control, in full compliance with the philosophy of the fourth industrial revolution.

Conclusion

Three reasons for turning to MWM? Here they are: fifty years of experience, wide-ranging collaboration and professional correctness.

Customizing is fine and useful, however to the right extent and only when needed.

Today, in the component sector we must operate in the ambit of the pre-and after sale service. It would be advisable to determine from time to time the rules to satisfy customers’ particularly requirements but clearly, without stretches, because the customization exacts that users are told the truth and that everyone takes the responsibility for that.

At MWM the customization is a job, in a certain sense each component is an experiment; the customization need has become stronger than ever but it must be neither sold nor sold off; it must be simply a sort of added value.