Reducing the quantity of the electrical energy consumption and at the same time improving the operating performances of the dryer/washer-dryer is possible thanks to the use of state-of-the-art heat pumps produced by Meccanica Generale.

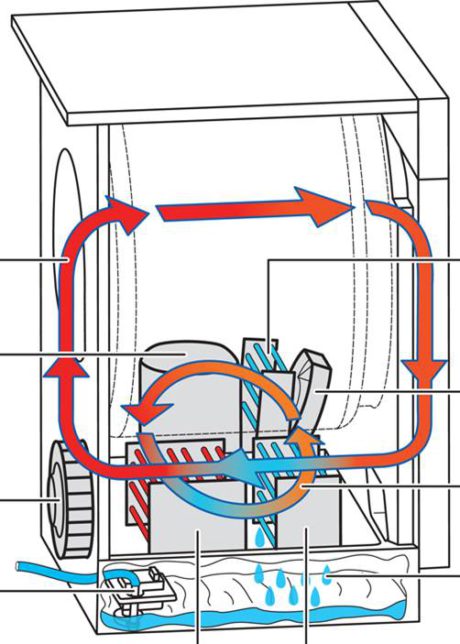

The use of the Heat Pump technology in household appliances, starting from “energy-eater” products, like dryers and washers-dryers, offers the opportunity of reaching high operating and energy-saving performances. The functioning scheme of the heat pump includes the action of two separate circuits for air-drying of textiles and the wetness condensate with the consequent water suction through the pump.

The process is based on the various control systems that allow managing cycle, temperature and wetness sensors. The research and innovation effort consists in the development of products able to reduce the energy load of the heat pump operation, at the same time enhancing performances with the possibility of installing the devices on already running machines, too.This is the goal of the prototype developed by the Italian company Meccanica Generale, first step for the development of a suitable heat pump for the installation on an existing washing group. It is based on the optimization of aspects such as the flow fluid dynamics in exchangers and in the washing unit, the use of a more efficient compressor and the improvement of the control logic of the drying cycle, in order to grant the 50% performance improvement.

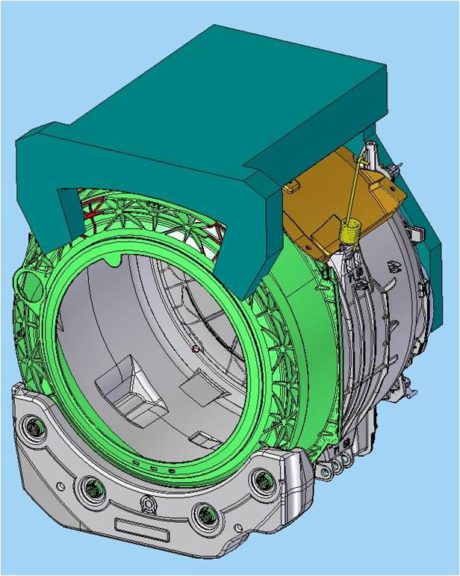

Tailored for household appliances: the study of the prototype

Target of Meccanica Generale was the development of a heat pump for the household appliance industry to be integrated into a conventional washing machine with standard cabinet, characterized by energy and drying efficiency, cost reduction and utmost integration among components. Started in 2011, in 2013 the project led to the implementation of the prototype undergoing tests. The implemented prototype has been integrated into an existing washer-dryer already available on the market. The appliance was modified to allow maintaining the standard market sizes (60×60) and this result is unique in the world panorama where other similar applications exist but have exerted a negative impact on outer machine sizes. The results of the various tests carried out have confirmed that the heat pump can provide the best performances of energy consumption and condensation efficiency compared to standard washer-dryer system. Further development steps have been undertaken, in order to enhance the efficiency and the efficacy of the heat pump devised by Meccanica Generale. Encouraging outcomes towards the manufacturing of the definitive prototype that will mark the success of this ambitious challenge.

SEE ALSO THE VIDEO: https://www.youtube.com/watch?v=cqfEatPNkiY