Efficiency, accuracy and performances: latest innovations made in Servomech

The ability to innovate and be ahead of the times is a constant feature for Servomech, since 1989 the international reference player in the design and manufacturing of linear actuators, acme and ball screw, ball screw jacks, acme screw jacks, bevel gearboxes and ball screws and nuts. Made in Italy, flexibility, customization, design and internal production with systematic controls during the whole production processes, with technical support are just some of the advantages of the company based in Bologna – Italy that has been able to gain a leading role worldwide with more than thirty years of activity.

New solutions for Servomech ball screw jacks

Considering an advanced industrial context, where more and more frequently the need for high speeds and continuous operations, as well as load and positioning control, the designers evaluate with great interest solutions with higher performances, easier to control (position, load and speed), and able to guarantee a competitive advantage in terms of quality and quantity of the work performed.

Based on this evolution, Servomech promotes a new concept in lifting systems, with an innovative approach, focused on the application of its high-performance ball screw jacks, with brushless motors and related drives and controls. Customers and designers are free to choose the brand of motors and drives they prefer.

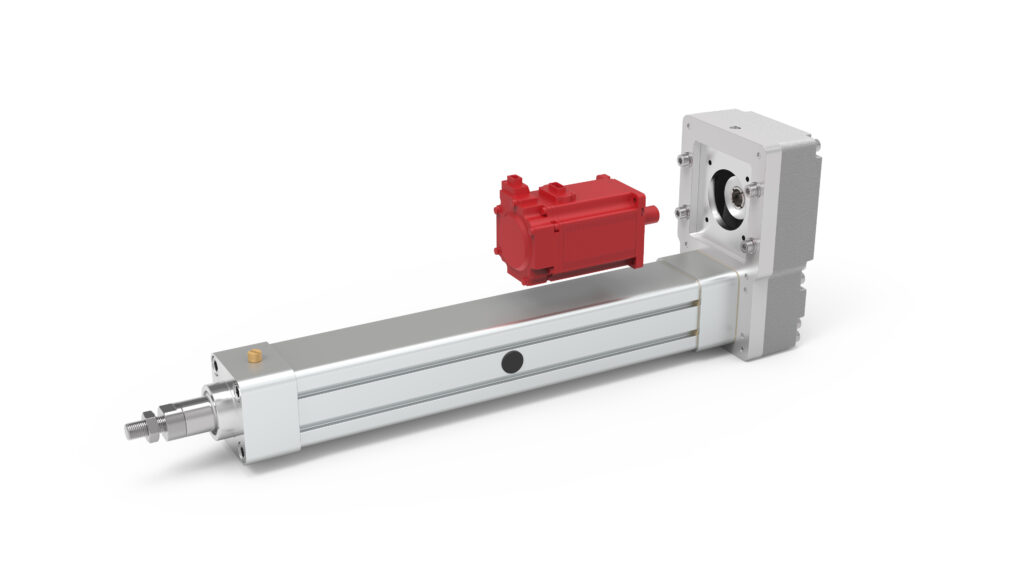

Among the innovations implemented by Servomech, a universal motor interface is now available to be combined with the range of ball screw jacks, thus allowing to combine the high performance mechanics of Servomech with third party servomotors. The new interfaces for brushless servomotors, like the whole range of Servomech products, are always made inside Servomech factory in Anzola dell’Emilia (Bologna) and are available as standard components with a great advantage in terms of faster delivery times and competitive costs.

High-performance

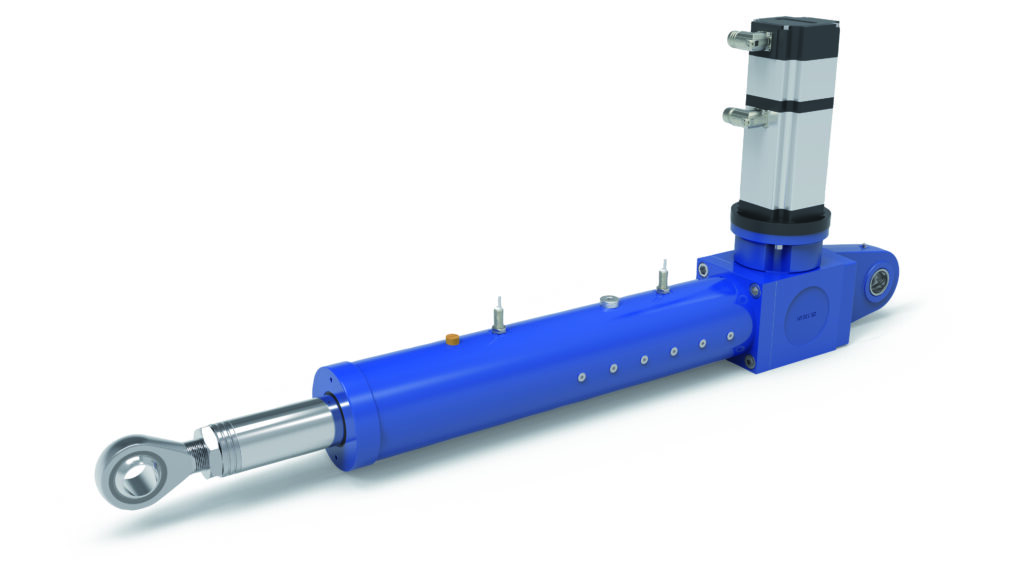

If we speak of product innovation and evolution, Servomech Group constantly releases interesting novelties on the market. Among them, a complete range of electromechanical cylinders that currently, due to their characteristics of efficiency, performances and precision, already represents a convenient solution to the problems concerning the use of hydraulic cylinders. Due to their design and implementation, the new Servomech electromechanical cylinders are more efficient products with lower energy consumptions. This result was achieved thanks to the attainment of higher efficiency, aspect that allows installing lower powers and consuming energy during the operation only. Another distinguishing peculiarity is the higher control of position/speed/force, i.e. the possibility of performing high speeds and loads under the precise and accurate position control. Among the main strongholds, worth signaling also the positioning precision in the order of hundredth of mm, the very high repeatability, constant in time, besides better safety and reliability: there are no risks caused by the high pressures and no oil leaks. Servomech cylinders are available in various assembling configurations, for a total interchangeability with the existing hydraulic cylinders. These new solutions assure also lower installation and maintenance costs and they can be implemented in special executions, designed according to customers’ specific requirements.

A new catalogue for Linearmech linear servoactuators

The continuous research and innovation implemented by Servomech are fully reflected in the new catalog dedicated to Linearmech Linear Servoactuators, with the latest information about the new SAM Series with universal interface for third party servomotors.

Ideal for applications with high operating dynamics, precision, positioning repeatability and reliability over time, all linear servoactuators are equipped with high precision ball screws, characterized by low inertia and zero backlash, ensuring high control of the position, speed and force applied. Linearmech servoactuators have a fully modular structure and are available in different structural typologies to allow their utmost use flexibility. Thanks to the new SAM series with universal motor interface the possibilities of use have been significantly expanded, allowing to combine the high performance of the Servomech linear unit with the servomotors of the main brands on the market. Available with parallel design and in line design, all servo actuators are equipped with a wide range of fixing elements according to the ISO 15552 standard for pneumatic cylinder for an easier installation.