Camozzi’s strategy is based on the development of specific sector competences coupled with a multi-technological approach that integrates pneumatics, electrical actuation and proportional technology.

Over the last few years, from a technological point of view, we more and more often witness rivalries that no longer concern only almost analogous products competing in terms of specific performances, quality and prices but real battels, at a higher level, to demonstrate the absolute predominance of this or that technology, and this is the case of the conflict between electrical and pneumatic actuation.

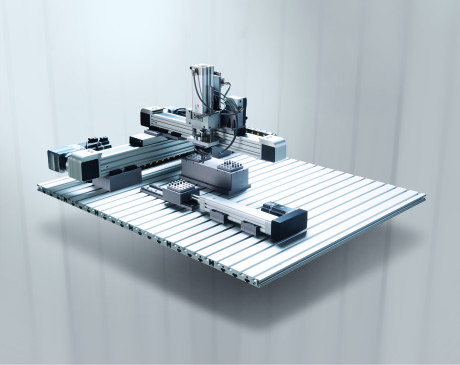

At Camozzi, we perfectly know that in the industrial automation sector each application features different and very specific requisites. Precisely to be able to satisfy all customers, we have widened our technological offer by creating C_Electrics, the new division that takes care of developing the electrical actuation by proposing solutions that include electromechanical cylinders and axes with related motors and accessory components, combined in configurable portals to grant the utmost flexibility for users.

The preliminary assumption from which we start is that there is no actuation technology that is absolutely better than another. Our belief is that each application has different requisites that can be satisfied at best thanks to the use of a specific technology: pneumatic, proportional or electrical. The use of the three technologies and the integrated proposal that our professionals can propose to customers, without incurring into divisional conflicts but with the only goal of optimizing the overall proposed solution, makes us very competitive. The possibility of combining the reliability of pneumatic valves and actuators, the control precision assured by proportional valves and regulators, the speed and the precision in the positioning of electromechanical axes and cylinders, optimizing the single motions and the performances required in the ambit of an industrial application, represent the competitive advantage that Camozzi can propose to its customers.

Another of the key points of Camozzi’s technological development strategy is represented by the service offered, which does not mean pre-and after-sale service only but concerns also the use of products themselves. Facilitating our customers in the choice and in the programming of our products wherever necessary. The idea that our customers’ time has a great value has led us to create Quick-set, highly intuitive and efficient configuration software for electromechanical axes and cylinders, able to identify the ideal solution for customers starting from the requisites of the application in terms of load, speed and accelerations requested.

Series 5E

The Series 5E axes are linear mechanical actuators where the rotational motion generated by a motor is converted into a linear motion through the use of a toothed belt. The series 5E, available in 3 sizes, 50, 65 and 80, is implemented by using a special self-bearing profile with square section, where elements have been fully integrated inside granting compactness and lightness.

The presence of a re-circulating ball guide confers high rigidity and resistance to external loads. To protect the inner elements from potential contaminations coming from the external environment, the profile has been closed by using a stainless steel foil. The axis is equipped with a magnet that enables the use of magnetic proximity switches (Series CSH), thanks to which it is possible to execute homing functions or extra-stroke readings. Besides, these actuators are provided with accessories for the use of inductive sensors. The Series 5E is equipped with specific interface kits allowing the execution of the motor connection on 4 sides. The use with high dynamics and the possibility of implementing multi-axis systems make the Series 5E very suitable for sectors such as packaging and assembling.

Series 6E

The Series 6E cylinders are mechanical linear rod actuators where the rotational motion generated by a motor is converted into a linear motion through the use of a re-circulating ball screw.

Available in 4 sizes, 32, 40, 50 and 63, the Series 6E has its sizes based on the ISO 15552 standard and therefore it is possible to use the fixing accessories used for pneumatic cylinders. Cylinders are equipped with a magnet that enables the use of magnetic proximity switches (Series CSH), thanks to which it is possible to execute homing function or extra-stroke readings. The Series 6E is provided with specific interface kits enabling the motor connection both in line and in parallel. High precisions and easy assembly make the Series 6E the ideal solution in many different applications, especially in multi-position systems.

Series DRWS and DRWB

The new Camozzi drivers in the two DRWS and DRWB versions have been studied to control the motion of the related motors. DRWB servo drivers, compact and optimized for Camozzi brushless motors, are fully digital and available in the 100 W, 400 W and 750 W power classes. Equipped with vector regulation with Autotuning function and vibration reduction, they are also provided with a two-line alphanumeric display with 4 control keys on the servo driver. A digital pulse interface allows controlling direction, position, speed and torque. DRWS drivers are implemented in a single size, purposely studied to control all two-phase Camozzi stepper motors with micro stepping feeding and they can calculate the natural resonance frequency of the motors and optimize their drive, thus also drastically reducing the natural friction in very slow rolling phase of stepper motors. This results in a higher motion smoothness and continuity at any speed. A function integrated into the driver allows minimizing vibrations in rolling inversion phase or in sudden speed changes. At the first ignition, DRWS drivers can calculate the inductance, the electrical resistance and the inertia of the connected motor and save such parameters to manage the drive at best.

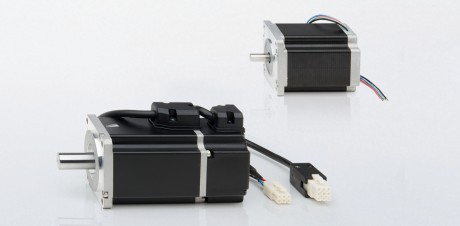

Series MTS and MTB

The new Camozzi motors in the two MTS and MTB versions have been studied to be connected simply and practically with the new range of electromechanical Cylinders and Axes.

The Series MTB synchronous AC brushless motors are available with 100, 400 and 750 W powers. Standard motors are provided with 13-bit encoder with 10,000 increments per revolution and are proposed with or without motor brake. Thanks to the high dynamics of these motors, it is possible to grant constant torque at all various speeds. Exploiting a low mass inertia, they are very suitable for high operation dynamics, such as sudden direction changes or high displacement frequencies. Series MTS electric stepper motors, in the sizes from Nema 14 to Nema 24, are available with single or double shaft, with or without brake, depending on the requirements of customers’ applications. Each motor version corresponds to a drive version that can be interfaced with the “QuickSet” configuration software, purposely developed by Camozzi to simplify the commissioning of the electrical actuator.