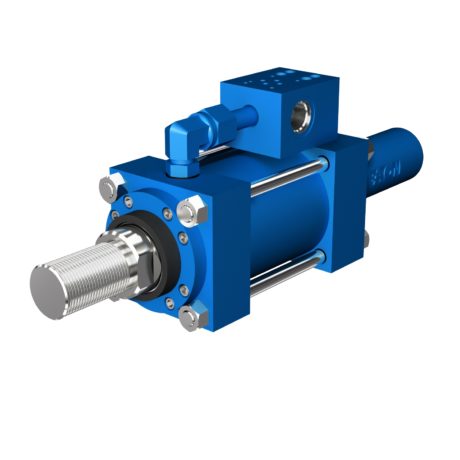

Power management company Eaton has announced the launch of a new electrohydraulic cylinder featuring valve integration. The new product comprises a high-performance industrial cylinder, precision feedback transducer and control valve in one package to create a single-source solution which offers significant cost savings over custom assemblies.

Power management company Eaton has announced the launch of a new electrohydraulic cylinder featuring valve integration. The new product comprises a high-performance industrial cylinder, precision feedback transducer and control valve in one package to create a single-source solution which offers significant cost savings over custom assemblies.

«With our latest electrohydraulic cylinder, customers and distributors no longer need to buy and assemble multiple components,” said Andreas Kling, Business Development Manager Power & Controls Products, EMEA, Eaton. “Our new cylinder is a complete system with the customer’s valve of choice pre-mounted on the cylinder. By eliminating the need for separate manifolds, plumbing between control valves and cylinders, transducer mounting brackets and other complex arrangements, we’re providing the benefits of custom assemblies while reducing the complexity and cost.»

Eaton’s electrohydraulic cylinder offers:

- Reduced setup time: Simplified plumbing and electrical connections, along with the programmability of the AxisPro® valve, eliminates repetitive set-ups.

- Waste elimination: Infinite positioning with high repeatability can improve yield in the production cycle.

- Increased production: Programmable motion control enables faster cycles than conventional hydraulic circuitry.

Eaton electrohydraulic cylinders are offered in NFPA tie rod, mill duty, welded or threaded styles, and are available with a range of mountings, bore sizes and rod diameters. An Eaton proportional, servo, directional control or AxisPro valve can be mounted onto the configured cylinder and adjusted to customer specifications.

To learn more about Eaton’s electrohydraulic cylinders, visit Eaton.com/EHcylinder.