A new alloy for bimetal cylinders developed by Nordson Xaloy features higher resistance to corrosion compared to iron-based polyvalent alloys that constitute the current European standard and allows longer service life, higher productivity, better process consistency and higher quality product, according to what communicated by the company today.

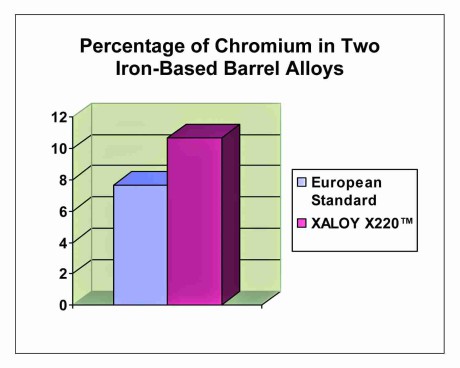

The X220 coating for extrusion cylinders and injection moulding is an iron, boron and chromium alloy, with a more than double chromium content than the X200 alloy already produced by Nordson Xaloy and exceeding by 40% the standard alloy diffused in Europe. In acid immersion tests carried out by Nordson Xaloy, the new X220 alloy has highlighted the 46% improvement compared to the European standard material in terms of weight loss of the specimen in sulphuric acid and the 31% improvement in hydrochloric acid.

In both tests, the X220 alloy scored better results than X200, an iron, boron and chromium alloy already produced by Nordson Xaloy, while in all corrosion tests it has achieved better results versus the European standard material.