At work in outer space thanks to Kaydon thin section bearings

Kaydon thin section bearings perform precise tasks in harsh outer space environment. Thin section bearings from Kaydon will once again go to work at the International Space Station (ISS) inside CAESAR, the Compliant Assistance and Exploration SpAce Robot. CAESAR will be installed in the ISS, roughly 250 miles (400 km) above the Earth’s surface.

CAESAR is part of a new generation of robots that combines innovative electronic and mechanical engineering. The 132 pound (60 kg) robot is equipped with a 10 ft. long arm that will perform scientific and commercial experiments regarding weightlessness. The exceptionally flexible folding robot arm is tasked with grabbing and stabilizing satellites that orbit erratically or have become unresponsive. The robot arm has seven degrees of freedom, the number of freely selected motion capabilities of the human arm, endowing it with greater flexibility than a standard robot.

Kaydon thin section bearings the obvious choice

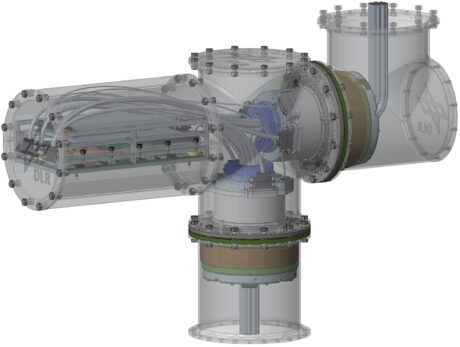

«Each articulation consists of a synchronous motor with a commutation sensor, a harmonic drive pinion and angular contact bearings, the torque sensor, and a common position sensor», said Erich Krämer of the German Aerospace Center (DLR), which developed CAESAR. «The choice of thin section angular contact bearings was made on the basis of their efficiency in absorbing both radial and axial forces, and their particularly space-saving design.»

Kaydon Reali-Slim bearings successfully guaranteed trouble-free movements for the articulations of the ROKVISS robot, CAESAR’s predecessor at the ISS.

«The bearings have demonstrated their effectiveness in space for years,» said Krämer. «Immense load-bearing capability, reliability, and indeed the experience in space applications were decisive arguments for choosing Kaydon thin section bearings.»

Trouble-free motion and force control

«The Reali-Slim series, on which the thin section bearings used here are based, can withstand the harshest operating conditions,” said Ulrich Schroth, product manager with Rodriguez, Kaydon’s German distributor, which manages the project. «They feature a compact design, outstanding precision, and are ideal for applications with such extreme demands.»

CAESAR can be operated semi-autonomously, by tele-command, or with tele-presence and force feedback. An impedance controller allows the arm articulations to yield and prevents them from damaging objects. The integrated torque sensor system detects unintended contact with the surroundings and enables appropriate responses, which represents a critical safety feature, particularly in cooperation with astronauts. Since there is no gravitational load in space, all connections have the same torque capacity. Fast-control circuits in the articulations and a high-speed, real-time communications bus connecting the articulations to the robot control unit ensure trouble-free motion and force control. The connective construction includes a hollow shaft to enable internal wiring.

The radiation hardness and service life of CAESAR has been set at 15 years of operation in geostationary orbit. The robot is designed for temperatures between -4°F and 140°F (-20° Celsius and +60° Celsius). The system may be adapted for other applications in the future, including various carriers, satellites, or spacecraft. “If a technology transfer of the CAESAR space robot to an industrial partner goes through, the cooperation with Kaydon will certainly continue as well», said Krämer.

About Kaydon

SKF is a leading global supplier of bearings, seals, mechatronics, lubrication systems, and services which include technical support, maintenance and reliability services, engineering consulting and training. SKF is represented in more than 130 countries and has around 17,000 distributor locations worldwide. SKF acquired Kaydon in 2013. Kaydon Bearings is a leading global manufacturer of standard and custom thin-section bearings as well as turntable and higher-level bearing assemblies for manufacturing and process industries. Kaydon supplies custom-engineered, performance-critical products, serving a broad and diverse group of industrial, aerospace, medical and electronic equipment, alternative energy and after-market customers. The company, which invented the thin-section bearing in 1943, is headquartered in Muskegon, Michigan, USA. www.kaydonbearings.com