Attilio Benvenuto –

Completing and improving the development of all elements of a tinting system: colorants, dispensers, packaging machines, tint meters, mixers, shakers, software, hardware, service and more. A four-hands project.

For over 15 years it has been one of the world leaders in the production of fully automated lines for producing In-Can products for the sectors of paints and varnishes, construction, industry and cosmetics, with dozens of installations in Europe, America, and Asia: CPS Color aims at being the industry benchmark for innovative technological solutions and reliability, by exporting them worldwide and moving towards new industries and new markets.

CPS Color globally completes and improves the development of all elements of a tinting system: colorants, dispensers, packaging machines, mixers, shakers, software, hardware, service and more. Moreover it continuously supports its customers in a targeted manner, from the initial design of the coloring system to daily management. Today it is present in all continents with 900 color professionals and factories in Italy, Finland, the Netherlands, India, China, Brazil, the United States; in 2010 global turnover was 181 million Euros.

Wider color charts, varying quantities

The evolution of the paint market has enabled the diffusion of wider color charts, leading to an inevitable reduction in average production lots and an increasingly wide variety of colors. This has significantly affected the margins of normal production processes per batch that are characterized by fixed cost which is not proportional to produced quantity. It has also resulted in longer delivery times that negatively affect the service level perceived by the customers, despite the required production efforts necessary to fulfill numerous small and medium-small lots, without considering the increase of finished products in stock. It is for these reasons that, in all areas, we are looking for increasingly flexible, efficient and cheap systems to quickly produce large amounts of colors, also in extremely small quantities, maintaining high margins and reducing waste, equipment washing and inventories.

Just-in-time quantity thanks to pneumatics

The project that CPS Color has developed, using Pneumaxproducts through pneumatic automation, responds to the new requirements determined by an always changing market and offers a number of significant advantages: producing and packaging at the same time, just-in-time, the exact quantity required by the customer, directly into the final container, reducing minimum lot size that can be profitably produced. This can be done by instantaneously turning from one format to another and from one color to another without interrupting the production process, completely eliminating wash basins, mixers, packers, etc.

The important role of compressed air

The collaboration began in 2000 when there was the need to use pneumatic components: presently CPS Color normally uses various types of pneumatic cylinders, solenoid valves and all Pneumax components suitable for the treatment of compressed air. Their use was born from the need to use products that have outstanding quality characteristics with extremely competitive costs.

Pneumax collaborates in consulting and preparation of components adapted to the needs of CPS Color, which sometimes go beyond the production standard. Now their partnership is established and Pneumax products were used also in new equipment design.

A recent application

A system made in Germany: a highly complex machine that aims at dosing basics of paint or colorants inside individual cans of different sizes or in a single tank, with a capacity of several hundred liters. Dosing occurs through metering valves moved by pneumatic cylinders and related solenoid valves. In this case 72 Pneumax cylinders are used, configurable up to 90. CPS Color chose Pneumax products also for the realization of other automated segments of the system that require efficient and reliable components for the treatment of compressed air.

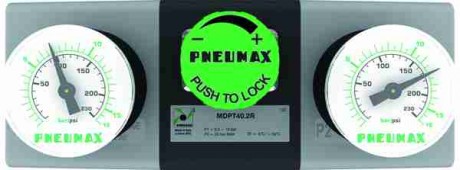

[box title=”The pressure booster P+” color=”#333333″]A concentration of performances, quality, design and lightness, the pressure booster P+ is presented with important and innovative features:

• small dimension;

• compact and linear design;

• IN-OUT-EXH connections – G1/4″ placed on the same side;

• integrated pressure regulator;

• multiplication ratio 2: 1;

• high flow rate and filling speeds;

• G1/8″ manometer connections for input-output pressure control;

• reduced weight.

Application fields

In some cases the force generated by a pneumatic actuator is not sufficient to carry out its required function. It is then necessary, where possible, to either increase the working pressure or use a larger bore actuator providing it will fit within the structure of the machine. If this isn’t possible, the solution is to use a pressure booster to increase the air pressure in a portion of the pneumatic circuit without replacing the actuator. The booster operates using the same compressed air used by the pneumatic system and does not require an external power supply. It is easy to install and allows increasing the working pressure in any part of the system where ever it’s needed, maintaining the normal working pressure in the rest of the system.The new pressure booster P+ is lightweight with a new compact and linear design. It has an integrated pressure regulator that adjusts the output pressure P2 and is also equipped with a pressure relief valve (relieving). Optimization of internal circuit provides high flow rates and fast filling times whilst the two G1/8” manometer connections built on the body of the booster allow monitoring input and output pressures directly on the device.

P +, the right solution for simplifying, lightening and maximizing.[/box]