Dana leverages spirit of collaboration and innovation cultivated in Trentino to develop next-generation drivetrain solutions.

The province of Trento has quickly become a vibrant center for innovation, with more than 20 public and private research centers, more than 3,000 researchers, and the internationally renowned University of Trento. Supported by Trentino Sviluppo and cultivated through public incentives and private investment, the region is a global nexus for entrepreneurial vision, technological innovation, sustainable development, collaboration, and a high quality of life.

To take advantage of these considerable resources, Dana Incorporated opened the Dana Mechatronics Technology Center in 2015 in the Polo Meccatronica di Rovereto. This cluster of companies, university departments, research centers, and startup accelerators helps Dana identify and leverage mechatronics system development opportunities with off-highway equipment manufacturers, facilitate co-development and networking opportunities with high-tech collaborators, and attract engineering talent.

The Dana Mechantronics Technology Center currently supports systems and components design and validation; technology evaluations and comparisons; proof-of-performance vehicle prototype development; feasibility and performance evaluations; and other advanced engineering functions.

Staffed by a team of engineers, researchers, technicians, and support personnel, the Dana Mechatronics Technology Center has been instrumental in the development of Spicer® Smart Suite™ technology, Dana’s groundbreaking platform for integrating connectedness throughout the drivetrain system. Introduced earlier this year at Bauma 2016, Spicer Smart Suite technology uses fully integrated, connected-vehicle features to convert operating data from the drivetrain into actionable insights.

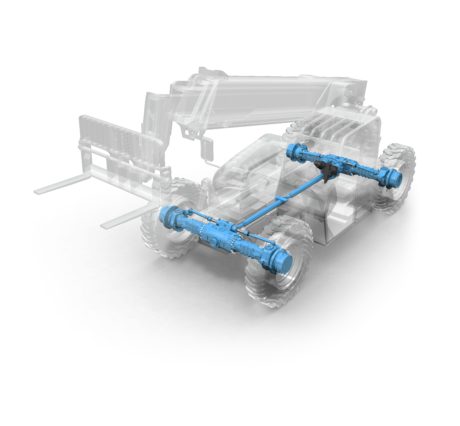

Spicer Smart Suite technology is an integrated system that collects, manages, analyzes, communicates, and acts on data sourced from the drivetrain. This technology communicates to end users on and off the vehicle, allowing critical alerts and analysis to be shared on vehicle central display panels, via tablets, and in fleet management centers. It is also designed to take these insights a step further by interfacing with vehicle controllers to perform key functions independent of operator intervention.

Spicer Smart Suite technology uses leading-edge machine-learning algorithms embedded into the software to optimize productivity and efficiency by recognizing, learning, and predicting vehicle and operator behavior. This process can virtually eliminate the need for vehicle calibration and allows operational parameters to be customized by taking into account specific machine characteristics, engineering tolerances, and operator tendencies. Dana engineers are uniquely qualified to evaluate, select, develop, and refine a full array of applicable machine-learning algorithms through the company’s decades of experience in analyzing and testing drivetrain components across a wide spectrum of off-highway vehicles.

Spicer Smart Suite intelligent load monitoring system is the first in a series of connected-vehicle packages that will be offered by Dana. Initially developed and tailored for telehandlers, this option uses data from across the vehicle to prevent tip-over incidents, provide better estimates of static loads, and supply intelligent calibration management.

The sophistication of off-highway equipment is growing at an accelerated rate, and manufacturers are rapidly adopting advanced technologies to achieve performance and efficiency gains. The Dana Mechatronics Technology Center leverages the considerable human capital, drive for entrepreneurship, shared culture of innovation, and spirit of collaboration actively nurtured in Trentino to deliver the advanced drivetrain solutions needed for the next generation of vehicles.

Learn more: info@dana.com, www.dana.com/offhighway

POLO MECCATRONICA: WHERE THE INTELLIGENT FACTORY GROWS

Polo Meccatronica is a project of the Autonomous Province of Trento. Trentino Sviluppo, a territorial development agency, is the “operative branch” of the province’s economic policy. The agency manages assets worth about 1 billion euro, in addition to 106 companies with 750 employees in 6 Business Innovation Centres. Trentino Sviluppo is implementing the mechatronics project hosting the entire cluster. The aim is the creation of a physical hub where enterprises, education and innovation systems work together to develop innovative projects with the leading support activity of the agency.

Polo Meccatronica renews the Business Innovation Centre of Rovereto – the first production plant, the Pirelli Cotton Mill, was built here in 1925 – with a main focus on mechatronic activities: mechanics, electronics, ICT, oil-hydraulics, pneumatics. The coexistence of different companies, secondary schools, university departments, research centres and startup accelerators creates the ideal conditions for experimentation and production of innovative processes and products.

Particularly important is the new building of about 6.000 sqm for Industrial R&D and prototyping, with 1.200 sqm for “ProM Facility”, a service platform for fast prototyping, 3D printing (metal and plastic) and the new “multifunctional” approach, software for CAD design and simulation, testing and quality assurance of products and mechatronics systems and sub-systems. “ProM Facility” is the ideal eco-system, inside the Polo Meccatronica, for schools, research centers and companies.