The Italian company Atam, among the leaders in the field of encapsulated coils and industrial connections, and Italmagneti, a specialist in the production of electromagnetic tubes for the control of solenoid valves and linear actuators, have collaborated to produce a new range of technically advanced solenoids for hydraulic users.

In recent years Atam and Italmagneti, operating collectively as the Atam Group, have excelled in the development of bespoke proportional solenoids, made to meet the specific application requirements of various industrial sectors. Currently, proportional solenoids represent one of the leading products offered by the two companies in Europe, the Far East and in the United States.

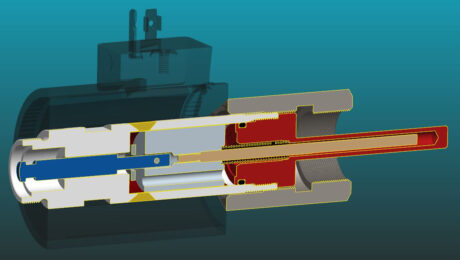

The solenoid for proportional valves, consisting of a perfectly integrated Atam coil and Italmagneti linear actuator, is a component that finds its final application in many hydraulic circuits used in the likes of agricultural machinery, earth-moving machinery, compactors and machines for urban cleaning, forklifts and concrete mixers. It facilitates for example the movement of the arm on a bulldozer or the rotation of a concrete mixer, by regulating the flow of oil and directing it where and when it is necessary, precisely maintaining the required pressure and flow rate.

A new family of solenoids for proportional valves

Recently, Atam and Italmagneti have developed a family of solenoids for use with proportional valves for several applications dedicated to earthmoving. These high-performance products are capable of operating with pressures of the order of 450 bar, where classic hydraulics reaches only 250 bar, and are tested for 10 million cycles, compared to approximately 1 million cycles of the traditionally used components.

Each solenoid is distinguished by the linear actuator which allows particularly low hysteresis values: this allows a very precise control of the solenoid valve, both with an increase and decrease in pressure. To obtain very low hysteresis values, special finishes were created on the internal components of the actuator to obtain very low roughness (0.1 – 0.15μm) and an anti-friction sheet was interposed between the internal wall of the actuator and the movable core to optimise sliding of the latter. Finally, the coil can reach an IP69K degree of protection; is supplied with all the most popular electrical connections on the market and is encapsulated in various resins to ensure the most suitable insulation class.

Wide variety of customised solutions

Atam Group can produce solutions with a high technical content, taking the customer’s outline specification and devising an outcome where the solenoid integrates perfectly into the components already in use. The Group also excels with its high level of production flexibility, with the ability to manage small scale production through to large batches on automated lines.

Atam Group offers the market a wide range of solutions developed for various application fields, also tailored on the basis of risk factors and the environments and extreme conditions in which the solenoid will operate. Typical pre-production considerations include valve group performance, extreme environmental temperatures or those characterised by marked thermal fluctuations or the presence of high corrosive phenomena and products situated in remote locations, where maintenance can be challenging.

The wide variety of customised solutions, combined with the speed and production flexibility ensured by the two companies, make Atam Group one of the major international players in the development and manufacture of solenoids for solenoid valves.

About Atam Group and Italmagneti

Atam Group was established in the 1990s driven by the need to develop a technical commercial synergy between Atam and Italmagneti, and to seize the opportunity to offer unique solutions for manufacturers that are technically advanced, and suitable for various hydraulic applications. The solenoid, which derives from the interaction of coil and operator, represents the heart of the valve and defines its technical performance.

The ethos of the Group makes it possible to propose a complete package of products both from a technical point of view (given that the two companies have the capacity to offer significant benefits as a result of the technical synergies that are present) and from a commercial perspective. Success on the market is in fact also linked to a shared action in terms of commercial conditions.

After the initial agreement between the founders of the two companies, both structures consolidated their positions on the global market ultimately achieving success linked to:

- Strong technical knowledge of the product and experience with final applications

- Proactivity in customer support

- Consistently high-quality products, coils and actuators

- A complete and competitive product range

- Synergistic commercial vision projected to the global market