FN/FC-FA safety brake is a single-disc spring applied electromagnetic brake in monobloc version, with state-of-the-art IEC or SAE (on demand) flanges.

The spring applied brake is open in operation conditions whereas in case of emergency or machine stop it closes, so performing the braking.

It is a brake with manifold characteristics that make it perfect in endless applications.

Its main properties are the following:

- The high flexibility given by the possibility of choosing the braking power, with customized calibrations as protection of gearboxes, moving loads and/or machines

- The long service life, due to the adjustability and possibility of being exploited until the life end, making it more durable

- The user-friendly “plug & play” assembly between motor and gearmotor

- The high centering precision, in the order of some hundredths

- The possibility of ascertaining its condition: open or closed by means of the sensor

- Low inertia

Like the other M.W.M. brakes, FN/FC-FA is 100% made in Italy, needs a short lead time due to the broad warehouse and it can be customized to better suit customers’ requirements.

An application example

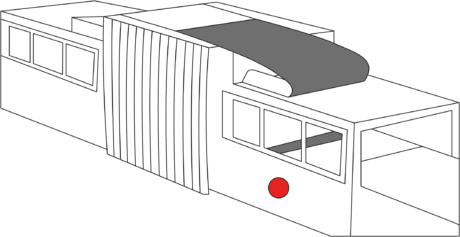

In the example shown in figure 2, the customer of M.W.M. freni frizioni srl has used FN/FC-FA in a machine for the coil handling. The brake installed between motor and gearmotor, as safety brake, is operated when the tension is off, so avoiding the fall of coils. Moreover, it is used in operation to stop the load in case of need. Finally, the brake has been made more compact to offer a better quality/price ratio to the customer.

Another application example is shown in figure 3. The brake FN/FC-FA is installed in a ceramic processing machine: here the brake stops the machine in case of lack of tension.

[su_box title=”An all Italian reality”]M.W.M. freni frizioni srl has operated for over 50 years in the world of industrial transmissions. Its products are 100% made in Italy: from the design to the production of components and to the assembly of finished products. The control of the whole manufacturing chain takes place in two factories: One intended for the production of components; One for the assembly, with guarantee of high qualitative standards and short lead time. The long-lasting expertise and the constant innovation allow M.W.M. to implement specifically customized solutions for the most complex and specific requirements. Each solution represents the synthesis between great expertise and contribution of forefront technologies for design, production and control. www.mwmfrenifrizioni.it[/su_box]

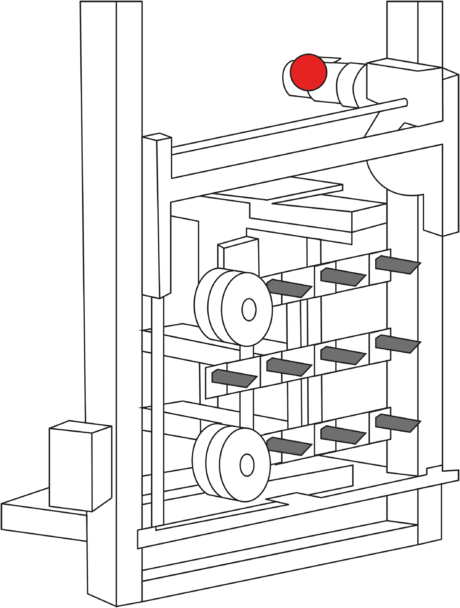

Fig. 1 – FN/FC-FA spring applied electromagnetic brake