EU regulations for road vehicles are becoming increasingly stringent. To reduce CO2 emissions, mechanical V-belts or power take-offs may not exist on future commercial vehicles. Energy-efficient electrohydraulic systems provide an alternative. The hydraulics specialist Bucher Hydraulics offers just such a solution with its latest range of Smart PowerPacks.

Regulations demand change

The facts are on the table: in 2019, the EU Parliament decided to reduce CO2 emissions from heavy commercial vehicles by 30 percent compared with 2005 levels and to achieve this by 2030. The first 15 percent must be achieved by 2025, i.e. in just three years, otherwise penalties will be imposed. Their amounts have not yet been determined, but they are likely to be painful. However, only road-going trucks are affected.

Vehicles such as garbage collection and municipal vehicles, or trucks with loading cranes are initially exempt from the regulation. But in the current year 2022, the EU Commission will discuss how to proceed in this area. In view of the increasingly dramatic climate changes, the regulations are likely to be noticeably strict. The report “Study of the Potential for Energy/Cost Saving in Fluid Power”, available for download free of charge from www.umweltbundesamt.de, commissioned by the German Federal Environment Agency has identified and evaluated various measures for construction and agricultural machinery. Applying the lessons of this report to these vehicles, the avoidance of idling periods and the demand-based control of auxiliary actuators are particularly promising.

No more power take-offs in the future

If the EU regulations regarding CO2 emissions are actually extended to other commercial vehicles, manufacturers of auxiliary units would be particularly affected. These auxiliary units include cooling water pumps or air-conditioning compressors, but also add-on equipment for municipal work functions or loading cranes. In conventional PTOs (power take-offs), hydraulic pumps are connected to the truck engine mechanically via a gearbox, a PTO shaft or a V-belt, and run continuously. In the rarest of cases, they can be disconnected by couplings. In the past, the truck add-on equipment in particular was rigorously trimmed for initial cost. This often meant the most basic technology, with power losses of 50 to 75 percent – incidentally, the reason why truck-mounted loading cranes, are often equipped with large oil coolers.

Diesel engines for trucks are optimized for driving at 80 km/h (50 mph) on the highway, where they operate very efficiently at low speed and high load. To generate the high flow rate required in stationary use(e.g. for loading work), the engine speed is increased – this is not only noisy, but also inefficient, as the engine then works at an unfavorable operating point, with poor combustion and high specific fuel consumption.

To reduce fuel consumption and thus the emissions of environment and climate-relevant gases, vehicle manufacturers are removing power-take offs from their product ranges in the future. Compressors, fans, steering and hydraulic pumps will be driven electrically using the “power on demand” principle, with no direct connection to the engine.

Smart PowerPack with internal speed set point

Electrification of the hydraulic power take-offs enables the use of power-on-demand exactly when it is needed. Hydraulics cannot be eliminated, as it is indispensable for linear movements with high force. However, the hydraulic system has to become more efficient in order to prevent costly power losses.

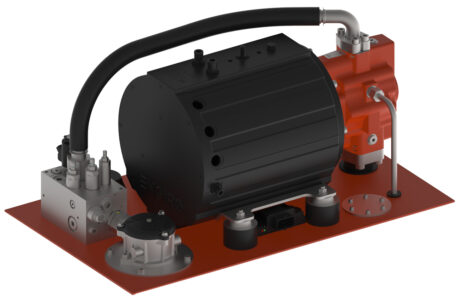

Bucher Hydraulics has developed the new Smart PowerPacks for utility vehicles with precisely this goal in mind. The required speed set point is generated internally. This is the key for energy optimized operation. Information on the application’s current flow requirement is not necessary. As a result, the Smart PowerPack solutions from Bucher Hydraulics can be freely combined with all commercially available hydraulic control systems.

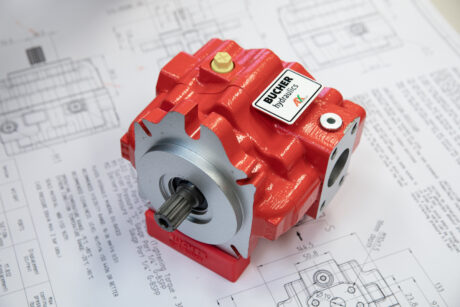

A key component for higher performance is the AX pump. It has 24 pistons and is specially designed for variable-speed applications. The large number of pistons keeps pulsations very low. The wide speed range from 0 to 3600 rpm allows the performance of the electric drive to be fully utilized: the minimum speed limit of conventional pumps does not apply to the AX pump, which can operate from zero speed and without any breakaway effect. With an overall efficiency between 92 and 94 percent, it far exceeds the values of conventional pump solutions. The system includes a smart hydraulic block, which generates the information on the actual flow demand and integrates the pressure relief function. The system uses inverters from Bucher Hydraulics Mobile Drives. These calculate the speed set point internally, which keeps the installation costs low.

The Smart PowerPack is now available in various sizes. In addition to the AX pump for high performance, the modular system also includes external and internal gear pumps, thus covering a wide range of applications. As many body manufacturers and retrofitters do not yet have experience with such electrohydraulic drives, Bucher Hydraulics offers the appropriate advice and design support.

(Graphics: Bucher Hydraulics)