The shipping sector has been also evolving for some time by adopting electromechanical technologies, benefiting not only from greater energy efficiency and performance but also in low noise, less bulk and less environmental impact. These are the strong points of the actuators that the Setec group designs and makes for this sector.

There are application environments such as the marine sector where lightness, compactness, quietness, safety and efficiency are by now increasingly necessary. Setec has included these features in the high performance Electromast and Seard series linear actuators, a range of patented components designed and made for application on pleasure vessels.

The solutions benefit from the in-depth experience and design and production skills built up by the Turin Group on all the main world markets for a wide range of industrial sectors.

“These actuators,” says director general and managing director Fabio Seminatore, “are without doubt the natural evolution of the pleasure vessel sector, which is making increasingly wide use of new electromechanical technologies. This change also means less environmental impact. And increasing care is being paid to this aspect.”

This added value goes hand-in-hand with the great care and attention to detail shown by Setec technicians in the Borgaro Torinese (Torino, Italy) production unit, which is fundamental for good product performance.

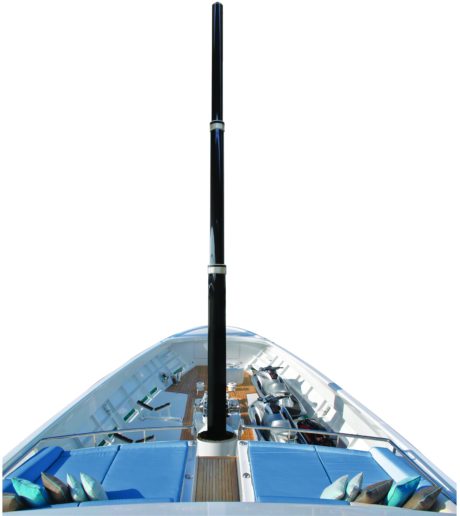

Born to hoist nav lights at the bow

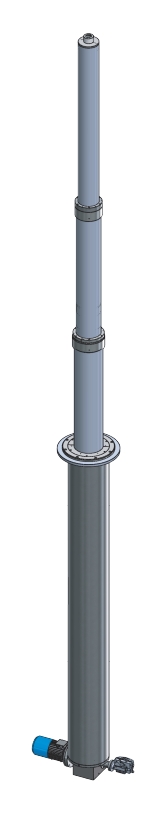

The Electromast is a purely electromechanical telescopic actuator consisting of three sliding elements in carbon fibre activated by transmission components in special light treated alloy.

Designed to hoist nav lights at the bow of ships of more than 50 m overall, the system is completely electromechanical and needs no hydraulic activation. It thus does not have a dedicated powerpack, pipes or valves and does not need hundreds of litres of oil to carry out the movements required.

“From an ecological point of view,” says Seminatore, “since it is a system with electromechanical cylindrical axial development with a twin effect, any oil leakage is into the hold and potentially into the sea are eliminated at the source. Then there is no risk of the rupture of hydraulic pipes under pressure with consequent risks of fire and sea pollution.”

Designed to be mechanically non-reversible, once in position Electromast requires no electric power. So it consumes little energy and only when activated.

“It is completely hollow,” says Seminatore, “and so the power cables of the lights can pass inside it. Thus they are completely protected, not on view and can be coiled by a mechanism at the base, giving an aesthetic as well as functional advantage. Remember that all that comes out of the flooring are the three patterned carbon fibre sleeves and the thick anodised aluminium flanges. In addition, thanks to transmission systems with intrinsically very low noise, the actuator overall is particularly quiet.”

The internal mechanical activating system is two-directional, it activates positively in both senses: for extending and collapsing the pole. So, if there are any salt deposits that tend to prevent it collapsing, the internal transmission pulls the three sleeves towards the inside, overcoming the obstacle. Setec has also taken great care to make it easy to install. Electromast has an upper flange, close to where the sleeves come out, to fix it rigidly to the structure of the ship. So yard technicians need only block it by fixing the external cylinder.

“Once the adjustable electromechanical end blocks have been calibrated,” says Seminatore, “to complete installation you need simply connect the electric cables of the three-phase motor of the actuator and the end blocks.”

Remote activation for the opening/closing of hatches, platforms, rudders…

Again for marine applications, Setec has designed, made and patented Seard, a purely electromechanical cylinder created for the linear activation of opening and closing systems for hatches, platforms, tender hoists, rudders and other elements.

“Like the Electromast series actuators,” says Seminatore, “precisely because they are purely electromechanical Seard electro cylinders too ensure compactness, respect for the environment, maximum energy efficiency and absolutely silent operation.”

Seard actuators can be remotely operated. They have a remote control system if the main motor of the actuator does not work which can be chosen from a mechanical unit with a special flexible cable or an auxiliary electric motor.

The standard version of the range can be in either axial or parallel configuration. In both cases four sizes are available (Seard 80, Seard 80 HL, Seard 100 HL e Seard 100 XL), giving maximum power, according to model, from a minimum of 12,500 N for the Seard 80 to a maximum of 55,560 N for the Seard 100 XL. For remote manoeuvring, the80 HL, 100 HL and 100 XL come into further versions, “8” and “12”, with power respectively from 12,500 to 15,000 N and from 25,000 to 30,000 N.

Also for Seard actuators installation is quick and easy and requires no particular additional costs: just for cables need to be taken to the electrical switchboard.

In particular, for electric helms the SEARD system, which is unique in the world, has “TYPE APPROVAL” certification from the R.I.N.A. classification body for steering systems.

Bear in mind that all products made by the Setec Group can be supplied in standard versions, as special models or be designed and developed ad hoc to individual specifications.

“Supplying customised products,” says Seminatore, “in addition to new solutions is for us a big strong point that sets us apart in the market. We can guarantee this thanks to our in-house mechatronic centre of where our engineers can develop highly customised technologies that are state-of-the-art and sometimes unconventional.”