A sound tradition behind, the guarantee of a family who has always run the company, the new challenges to grow further in Italy and on international markets.

In 2021, ZEC Spa crossed the important finishing line of sixty years of activity, which today have led it to rank among the leader companies in the world in the sector of thermoplastic hoses, backed by a very broad range that includes linear, single, multiple and spiral hoses, both standard and special, with technical specifications that allow you to choose inside diameters ranging from 2 to 40 mm, with working pressures from 5 to 1280 bars and extreme working temperatures, between -200°C and +260°C, depending on typologies. Nowadays, the products by the company headquartered at Colorno (Parma, Italy) are distributed in over 50 Countries, supplying many of the primary markets.

Dino Zantelli, Managing Director, talks with us about a reality that goes on investing and believing in its growth, anyway soundly rooted, since when, in 1961, the father Eugenio started the activity by setting up a small laboratory that soon specialized in the production, at that time pioneering, of plastic hoses, making ZEC the first Italian company able to implement the SAE100-R7 standard hose.

«These are – states Dino Zantelli – the preliminary conditions that have led us to represent a pioneering company since the early phase, with the vision of succeeding in building a sound reputation in a historical time when in Italy the sector still was to be fully structured. Today, besides a constant growth of our export, which represents 65% of the turnover, we can proudly affirm that many customers and partners that have accompanied us since the beginning of our adventure are still with us, sharing our philosophy. Moreover, every year 6-7% of the turnover is invested to implement the research and development sector».

Leap of quality

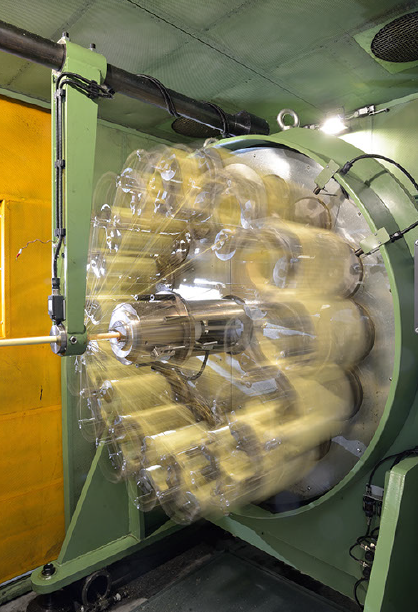

Once laid by the father the foundations to create a sound company, the second generation of Zantelli family, with Paolo and Dino, has worked to make a further qualitative leap, consolidating a success first almost exclusively based on word of mouth and deeply changing a reality that currently can produce 40,000 kilometres of hoses every year and has structured the distribution network in Italy and abroad, also believing in a more up-to-date capability of promoting products through marketing and communication. «Since the Nineties, we have started investing huge resources to equip ourselves with state-of-the-art machines for the extrusion and implementation of hoses. We rely on such a manufacturing capacity as to allow us to implement dedicated lines according to the material, the hose size and typology, with evident time savings due to plant changes and then to production efficiency enhancement.

Besides, the introduction of computerized processes and more and more punctual manufacturing control systems provides further flexibility, to overcome production peaks and to manage at best the times to fulfil the orders received». Flexibility also completed by the possibility of ensuring supplies with constant quality in time, permitting ZEC to establish itself also as supplier of outstanding national and foreign OEM. All catalogue products, over 1500 items, are implemented in compliance with UNI EN ISO 9001:2015 Quality System and in conformity with the international regulations of the respective application sectors, such as SAE, EN, DIN, ISO. In manufacturing, quality and flexibility are fundamental, as well as the scrupulous control of the whole chain. All raw materials that enter production departments are inspected and tested to ensure the conformity with the severe guidelines of the company’s quality control, overcoming specific Laboratory tests, from the simpler three-dimensional controls to chemical analyses, to succeed then in assessing the finished product with pressure Tightness tests, checking the Burst pressure, Fatigue Tightness tests with Impulse Pressure Test, everything with the guarantee of complete batch traceability. For low-pressure applications, ZEC’s primary use materials are RILSAN® and PA12. The hose range includes single, multiple or spiral hoses made of PA12, PU, TPE, PELD and fluoropolymers such as PTFE, FEP and PFA for high-temperature applications. For medium, high or very high pressures, ZEC’s hose range includes textile fibre reinforcements, carbon steel wire, AiSi304, and aramid fibre braid solutions, as well as hybrid solutions mixing steel and aramid fibre. ZEC offers also a range of Steel Couplings, protective sheaths and accessories, to complete one of the broadest ranges of thermoplastic hoses and related accessories for the Fluidic world.

New spaces to grow

The will of investing to grow has stopped neither during the pandemic period when ZEC Spa, besides releasing numerous product novelties, has enlarged its staff with 20 hires, so grazing today 140 employees and, especially, they have worked to accomplish the project of a new production structure, the third, taking up over 5000 m², extending to over 21,000 m² the surface covered by Colorno headquarters, completed by a plant used as warehouse with more than 4000 Pallets places. Although not at steady rate, yet, also the new site already shares in the effort to increase the manufacturing capacity, which suits the export rise trend and for which in 2022 a possible increment and consolidation of last years’ results are expected.

«The will of growing – Zantelli adds – goes on keeping pace with the capability of facing the market with extreme flexibility, due to our interaction skills that result in the development of new products. These investments not only will allow us to increase the production, but also to offer a more and more complete range. From this point of view, I would like to mention the direct investments that next months will lead us to present special connected hoses for the refrigeration industry, as well as spiral hoses able to operate in applications for very high pressures. At the horizon, a strengthening of our presence also in the chain of plants intended for the transport of methane (CNG) at high pressure. Our intention is to go on enhancing our ranking in all main industrial regions in the world, controlling at best all reference sectors: from hydraulics to pneumatics, from automotive to the food industry, from the petrochemical to general industry, but also entering rising markets, such as green energy one, structured in the branches of sun, wind and hydrogen energy. Our target is not consolidating our ranking in the Italian market but also in the foreign one, working to structure our distribution network even better, to comply at best with the trends and the developments of a constantly-changing market».