High-precision flowmeters. Metal Work extends the range of the devices for the measurements of the compressed air flow rate in the pneumatic plant with the new 1 and 2 sizes of FLUX series

Metal Work Spa, company specialized in the manufacturing of pneumatic components for industrial automation with headquarters at Concesio (Brescia, Italy), has recently presented the new flowmeter Series FLUX in the 1 and 2 sizes. It is a device that can be used to measure the flow rate of compressed air in various zones of a pneumatic system, to monitor losses or to dose a precise volume of air and of inert gases.

Total control

Before this novelty, Metal Work proposed the only miniaturized FLUX 0 version, to be used to measure flow rates up to 200 Nl/min. FLUX 0 is equipped with a three-colour display that allows visualizing and setting up numerous functions and relies on 2 digital outputs and on an analogic one, each of them can be set up freely to measure the instantaneous flow rate, the cumulated flow rate or the pressure, so being able to carry out the function of flow meter, flow switch, pressure gauge or pressure switch. The new versions measure flow rates up to 2,000 Nl/min (FLUX 1) and 4,000 Nl/min (FLUX 2). They consist of a sturdy anodized aluminium body with G ½” (FLUX 1) and G 1” (FLUX2) input and output threads, on which the electronics for measurement and control is mounted. A flow linearization device is installed at the inlet and it guarantees an excellent measurement accuracy; they can be mounted in any orientation and it is possible to rotate the screen by 90° 180° and 270°, so permitting a comfortable data reading. FLUX 1 and 2 flow meters can be used individually or integrated inside an air treatment group of Syntesi series.

Multitasking products

The new flow meters are available in the versions with or without display, always with M12 connector for the power supply and signal control. The devices can be powered with voltage ranging from 12 VDC (-10%) to 24 VDC (+30%). The versions with display are also provided with a pressure and temperature transducer that, through the algorithm implemented in the software of the device, allows minimizing the measuring error inside the temperature range indicated in the catalogue. All versions feature IP65 protection degree. Flow rate, pressure and temperature values are visualized on the display, as well as graphs of instantaneous and cumulative magnitudes. Moreover, the value of electrical power used to produce the measured flow is also calculated and displayed.

From the communication point of view, we have at disposal a digital PNP output, which can be configured on the value of flow rate, pressure and total consumption, and an analogue output that can be set in voltage (0-10 VDC) or in current (4-20 mA). Versions with IO-Link interface with similar characteristics are available, too. As it happens for the previous version, also the new FLUX 1 and 2 can then be used as flow meter, flow switch, pressure gauge or pressure switch.

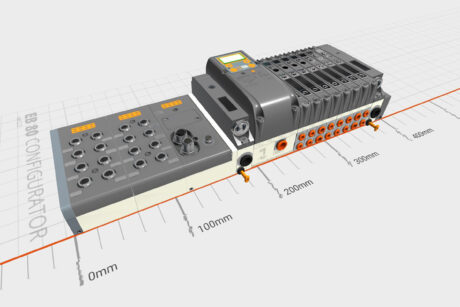

New EB80 configurator

Moreover, Metal Work Spa has decided enhancing its proposal of tools that help customers in the choice of the best solution for the specific application. Aware of this issue, the company has in fact already developed along the years a series of Engineering Tools freely accessible from its site. Among these products, the latest implementation is the new EB80 configurator for the composition of solenoid valves islands. It is a forefront tool that facilitates the creation of an island through a powerful graphic engine, intuitive functions and agile algorithms for the island composition. The user, by means of few steps, can create the island, graphically control the result, modify it, if necessary, save it and reload it. Moreover, he can switch quickly to the system of eCommerce Metal Work to enter the technical documentation, to download 2D and 3D and to order it online.

The operation

The access to the configurator can occur freely from Metal Work site. A simple graphic drag & drop tool allows the positioning of the various elements on the screen. The island is generally created starting from the electric connection module, which determines its typology: concerning this, the user has all elements at disposal, for both the multipole and the fieldbus connection.

Therefore, it is possible to add and to configure in succession all other elements (bases, valves, power supplies, intermediate modules, signal modules and pressure regulators).

At each step, some specific icons allow doubling, replacing or eliminating any item. Moreover, there are various assistance menus that allow completing the missing information, such as the specific typology or pneumatic supply ports for whatever element. At any time, the user can modify the objects, add new ones, modify or eliminate the existing ones. Once implemented the desired sequence, it is possible to save it, to recall it or to modify it afterwards, too. Besides, it is possible to enter manifold configurations already created or saved by other users and, once created the wished island, it is possible to shift with a simple click to the eCommerce system by Metal Work.

New Secure Lock series

The devices of Secure Lock Series represent a further product novelty. First of all, they assure an excellent rod lock of ISO 15552 pneumatic cylinders, in the sizes from ø32 to ø125.

The device performances are assured by a tapered-sliding locking system, with balls interposed between plates and self-retention springs; the machining of extreme accuracy and the typology of materials and treatments share in a certain and precise system locking. Therefore, Secure Lock grants a repeatable locking in time, and can intervene in case of occasional situations of dynamic stop. Moreover, it features a very low backlash that makes it ideal for good accuracy applications. Unlocking takes place by powering the air intake on the device body or by means of a manual actuator (in the codes where it is provided for). The manual release function mechanically disengages the stem lock with the simple rotation of a pin that acts on a cam; once released, the pin automatically returns to the condition of “locked stem”.