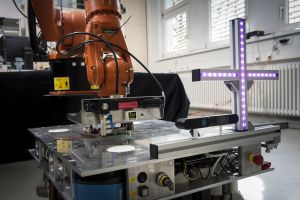

In the future, even small series of individualized products might be manufactured rapidly and efficiently by means of intelligent machines that communicate with each other. This is why, researchers of the Karlsruhe Institute of Technology (KIT) coordinate the SkillPro EU research project, that is aimed at finding innovative solutions to considerably reduce changeover times in the production process. Having completed one order, manufacture of any new product ordered mostly requires a modification of the production process. When manufacturing small series, preparation, setup, and programming of the machine park often take much longer than manufacture proper. A machine equipped with camera sensors, for instance, can recognize any workpiece even in case of changing products. Having examined the workpiece’s shape and position, the machine can decide how to apply its gripper or suction caps and where to place the workpiece. Depending on the product, machines having gripping, welding, or bonding skills can determine their next task or production step.

In the future, even small series of individualized products might be manufactured rapidly and efficiently by means of intelligent machines that communicate with each other. This is why, researchers of the Karlsruhe Institute of Technology (KIT) coordinate the SkillPro EU research project, that is aimed at finding innovative solutions to considerably reduce changeover times in the production process. Having completed one order, manufacture of any new product ordered mostly requires a modification of the production process. When manufacturing small series, preparation, setup, and programming of the machine park often take much longer than manufacture proper. A machine equipped with camera sensors, for instance, can recognize any workpiece even in case of changing products. Having examined the workpiece’s shape and position, the machine can decide how to apply its gripper or suction caps and where to place the workpiece. Depending on the product, machines having gripping, welding, or bonding skills can determine their next task or production step.