Fait Group produces and sells components and systems for linear motion, bearings and power transmission on the national territory, in Europe and worldwide. Among them, Tecnoline is the proprietary brand that identifies a broad range of linear units for automation.

«Initially conceived as proposal to the single-axis market – explains the product manager, the engineer Lorenzo Mattei – the brand, and then the whole range, has been developed greatly in time, hand in hand with the rising applicative requirements. This evolution allows us today to support our customers in the implementation of increasingly complex and performing automation systems and multi-axis multi-motion machines».

The company’s strong point resides in the high-speed response to the market’s demand, providing a specific solution, which often can be found in our standard product range, but can be also created according to precise requisites.

«In other words – Mr Mattei underlines – after listening to specific requirements, we support customers with co-design and co-engineering studies, to succeed in concretizing a genuine tailor-made solution, fully compliant with expected performances. A constant relationship between respective technical offices aimed at easing the final purpose achievement in the shortest time possible ».

Therefore, Fait Group proposes itself not only as a supplier of a high-quality product but also as a technological high added-value partner.

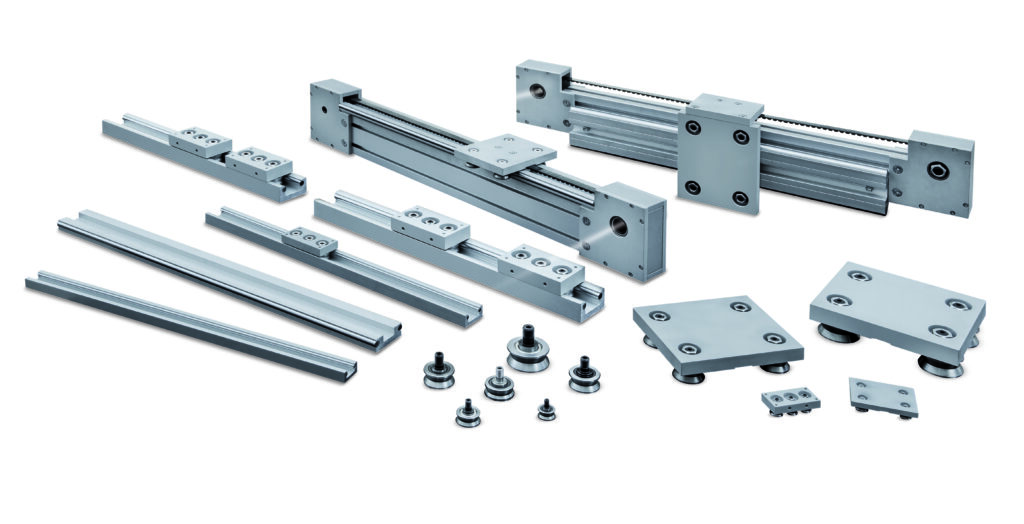

Linear motorizable modules with toothed belts, re-circulating ball screws or trapezoidal screws, with rack and pinion

Tecnoline linear axes are positioning systems designed by pursuing high performances, quality, and structural simplicity. Their transmission compartment can be entrusted to polyurethane toothed belts with high-strength steel strands, re-circulating ball screws or trapezoidal screws, pinion-rack coupling.

«These systems – Mr Mattei specifies – consist of anodized aluminium profiles or aluminium/steel plates, where linear re-circulating ball guides with high loading capacity are installed».

The range of linear axes is completed by a wide line of accessories (fixing sliders, mechanical/inductive limit switches, prearrangements for motors) that allow units to suit the requisites of the various applications. Catalogue ranges are various, subdivided according to offered performances and the work environment where the application will be positioned.

TLE axes series represents the base version, largely adopted in several applications and available in two sizes: 55- and 80-mm for the implementation of a single axis. In this case, the transmission task is entrusted to toothed pulleys made of burnished steel and polyurethane toothed belt with high-strength steel strands.

«TLM, TLY and TLZ systems – Mr Mattei adds – they too belt-operated, are instead studied to provide excellent performance levels for multi-axis systems, that is to say motions on each respective axes».

The TLZ series is conceived to satisfy vertical motion requirements in gantry applications (palletizers, robots). This axis typology stands out from others for the method of use as the carriage remains fixed while the aluminium profile is in motion.

«The TLC series – Mr Mattei further explains – whose actuators consist of a self-bearing anodized aluminium structure in 180, 200, 220 and 240 sizes, differs instead from the previous ones for the transmission field entrusted to a toothed rack and pinion system ».

In this case, it is a technological solution that can be used wherever applications need higher precision and speed levels, and high stiffness features, with possibility of assembling on the axes straight-tooth racks or inclined-tooth racks made of tempered steel».

Linear motorizable modules with rollers and linear track roller guides

In addition to motorizable linear modules with toothed belts, re-circulating ball screws or trapezoidal screws, rack and pinion, Fait Group also provides a broad range of track roller motorizable modules series GD, GS, IL and ILM.

«These executions – Mr Mattei ends – find their natural application wherever for instance the presence of dusts in the environments can be noxious for re-circulating ball pads, although particular protections, shields and casings of various kinds are available».

[su_box title=”The company in brief”]Established in 1976 as small reality in industrial technical supplies, Fait Group succeeds in a short time in becoming a benchmark for spare parts and technical support. This result is made possible by the high technical competences and a widespread presence on the territory, which allows the company to widen more and more its operational borders. With headquarters in Prato province, today the company boasts a structure subdivided into four operational, manufacturing and commercial, divisions, which in their turn define the different lines of technical solutions proposed to the market for the implementation of specific products, connected with its customers’ requirements. Present with its own products in various areas in Europe, with its sales and representation network strongly rooted into each market, Fait has belonged to the French multinational Descours Et Cabaud for some years now. Service, product, and quality support are assured at Fait by the around 80 skilled people who compose the staff, together with state-of-the-art technologies constantly innovated and integrated in production. [/su_box]

(by Gianandrea Mazzola)