Since more than 25 years, the Servomech Group is specialized in manufacturing electromechanical linear actuators acme and ball screw drive, mechanical jacks with acme screw, screw jacks with ball screw, ball screws and nuts.

The latest new products and inventions of Servomech Group are more and more advanced mechatronic systems and solutions to meet the new application requirements of today. The main strength of Servomech Group is to manufacture everything inside. From design to construction, all the processes and innovations are made inside the Servomech factory in Bologna – ITALY, relying on total control of the entire production cycle and highly qualified and skilled staff.

Confirming the importance of making continuous investments to innovate and to grow, Servomech decided to expand the existing production space (about 9,000 square meters) with a third building of 5,200 square meters, solely dedicated to production. The plant is already completed and will be opened in the first half of 2016. Together with this project for production expansion, in the next five years it is also estimated a new recruitment program for about 40 new high-qualified profile employees, to be added to the existing 100 people totally employed.

Efficiency, performance, accuracy: Servomech new cylinders

Referring to innovation and product evolution, Servomech constantly releases interesting novelties on the market. Among them, also a range of powered electromechanical cylinders and a series of electromechanical servo-actuators, as the real alternative to hydraulic and pneumatic cylinders.

More in detail, the new range of electromechanical cylinders constitutes a convenient technological innovation to solve the problems connected with the use of hydraulic cylinders. Due to their design and manufacturing, the new cylinders provide higher efficiency with lower energy consumptions. This is made possible thanks to the high efficiency of the system, aspect that allows installing lower powers, consuming energy only during the operation. Besides, another distinguishing peculiarity regards the higher position/speed/force control, that is to say possibility of performing high speeds and loads under the precise and accurate position control.

Among the main strong points, it is worth highlighting also the positioning precision in the order of hundredth of millimeter, the very high repeatability, constant in time, in addition to better safety and reliability (no risk due to high pressures and no oil leakage, and possibility of receiving exact documented calculation concerning the component service life). Available in various assembling configurations for a total interchangeability with existing hydraulic cylinders, these new cylinders grant also minor installation and maintenance costs, and can be implemented in special executions designed according to specific requirements.

Since only power supply and signal transmission cables are necessary, also connections are simpler and, absolutely not negligible aspect, even long periods without operation and maintenance can elapse and they are always ready to use.

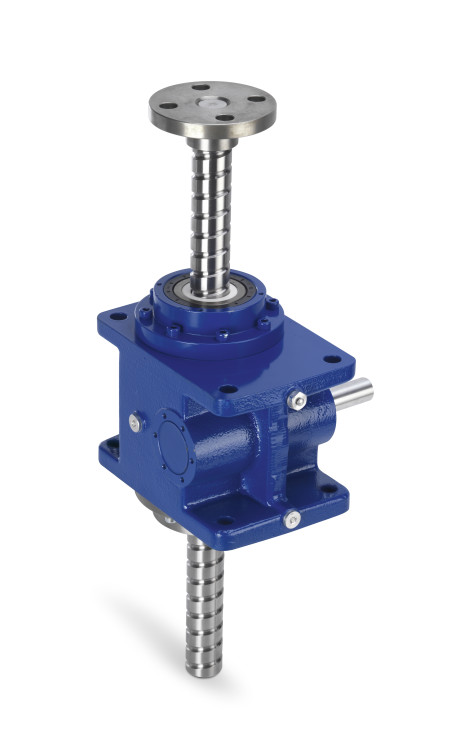

Native integration, technological evolution and new patented design with Servomech ball screw jacks

Among the recently released products by Servomech Group also appear new screw jacks. This solution, featuring Servomech ball screws, allows overcoming the limitations of traditional acme screw jacks. High linear speeds, operation duty cycles also continuous, no problem of wear in the nut and no axial plays, exact calculation of components lifetime, finally they allow to halve both energy consumption and the installed power.

In particular, the solution with translating ball screw MA BS Series Mod. A is made with an innovative patented design. Due to internal Servomech design and manufacturing of all the components (including ball screw and nut) it was possible to design a native integration of all the driving elements within the body of the jack. The result is not only higher performances and greater positioning accuracy, but also greater rigidity by compact dimensions. The advantages that the market can take from this solution are immediate reduction of costs thanks to an efficient optimization of product and performance, lower power consumption, greater load capacity at same size, greater rigidity of the structure thanks to native integration of all the components.

Servomech ball screw jacks are available in 8 sizes, with loading capacity from 5 to 350 kN, ball screw diameter from 16 to 120 mm, input speed up to 3,000 rpm, linear speed up to 2 m/s, continuous duty cycle. Servomech ball screw jacks can be fitted directly with the new series of brushless servomotors standard IEC interface made by Linearmech. This expands surprisingly the application scenarios of this product. Linearmech drives are totally made in Italy and their functions are totally integrated with brushless servomotors. Thanks to the specific mechatronic functions to manage even complex load and speed profile, the positioning control, the torque control and the speed control are very easy and simple.

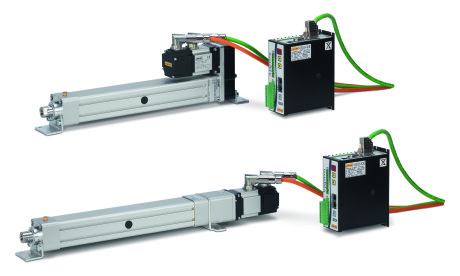

Linearmech electromechanical servoactuators: high-speed performances with total control

Linearmech is the specific division inside Servomech Group for automation and mechatronics. The new electromechanical servo actuators developed by Linearmech are the real alternative to pneumatic cylinders. In-Line design and Parallel-Design construction, they are available in 7 different sizes to cover a wide range of performances.

The new products from Linearmech allow the traditional users of pneumatic cylinders to make faster, more accurate and more compact machines, by reducing energy consumption and managing all the axes by the central intelligence. The new range of electromechanical servo actuators SA Series includes 3 different types of construction, pure linear mechanical unit without servo motor, or the complete package including Linearmech servomotor in-line or parallel design mouting, in the same linear drive unit and with a modular construction. Seven different standard sizes, designed to cover a wide range of performances. Sturdy and compact, these linear servo actuators are provided with ball screws all made by Servomech (different accuracy classes available depending on the specific application requirements). Also available a wide range of connections and accessories according to standard pneumatic cylinders ISO 15552.

Dear sir subject

Roll lifting size 200 karna hai