Specialized in the design and production of electric motors, mechanical gearboxes and inverters, the Italian company Motive has recently widened its product range with a new solution dedicated to the automatic pressure control in hydraulic systems and with an island or hybrid drive for solar pumps and motors.

Motive has always made product and service innovation its distinguishing trait, allowing it to consolidate in time an outstanding market position in the ambit of the design and production of electric motors, mechanical gearboxes and inverters.

«Innovating– explains the managing director Giorgio Bosio – means anticipating the market and its needs, instead of being subjected to it. It means refining new products where can merge competences and know-how aimed at the development of solutions and systems able to satisfy increasingly diversified application needs and requisites».

An operational approach that has led the company headquartered at Castenedolo (BS) to become a reference partner, with a wider and wider product range that can satisfy the most varied requirements.

«A range – adds Bosio – that in the inverter ambit has been recently widened by the introduction of the new Neo-Pump, specific VFD for the automatic control of water pumping systems and by the new Neo-Solar, island or hybrid drive system for solar pumps and motors».

Automatic control and regulation of plants

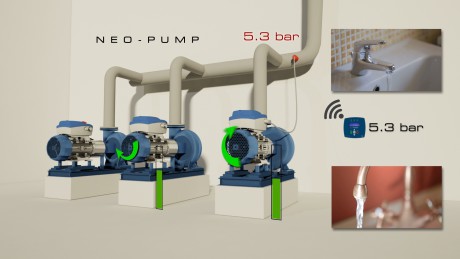

Evolution of the well-known remote-controlled and patented Neo-WiFi, the new version called Neo-Pump has been devised, designed and developed for the automatic pressure control and regulation in hydraulic pumping systems.

«At the project base – goes on Bosio – the precise will of developing a high added-value product that, due to intrinsic technical peculiarities, was able to provide a real operational advantage for end users. Starting from the annulled need of equipping the plant with shutters/valves, cabinets, knife switches, motor overload protection automatic switches, motor control relays. In other words, components generally used in conventional systems».

Minor number of components means a simpler system, less subjected to possible anomalies and more efficient, too. Efficiency dictated also by the fact that, in virtue of its technical nature, the inverter uses a power that is proportional to the demanded water quantity. Thanks to a physical law connected with the fluid motion, the minor is the water used the exponentially lower are the requested power and the energy consumption. As known, in more conventional plants that operate without inverter, you consume instead always the maximum power of all pumps altogether, irrespective of the real water demand.

«The gradual and soft start as well – adds Bosio – leads to an interesting energy saving, if compared with standard systems where we can notice not only an abrupt start but also temporary peaks of overcurrent, and therefore of over-consumptions».

Two are the models supplied by the company, one with 3 kW of power and one featuring 11 kW, easily installed and commissioned since the early phases. In master-slave connection, their power multiplies and suits with any size of pumping system. In comparison with standard pump inverters that require the input of various data concerning the pump flow rate and head, since the first start, Neo-Pump carries out an auto-tuning automatically. This allows detecting and registering the characteristic pump curve and adapting its operation to the system, without needing eventual additional calculations and/or inputs.

«Not only the installation is simple– adds Bosio – but also the use. In a master-slave system, for instance, you can comfortably adjust the pressure from both the master and from the slaves. Not to mention the already known operational user-friendliness granted by the Wi Fi keypad, still equipping the Neo series, which permits the remote programming and control (up to about twenty metres, editors’ note), and wireless, thus assuring a drastic reduction of installation costs».

Moreover, the new inverter grants an alternate operation, optimized and targeted to maximise the service life of each pump. The prearranged internal algorithms can instead detect and eventually adjust the pressure in fully automatic modality, without needing any manual intervention.

Island system for solar pumps and motors

As already underlined, product innovation and evolution represent for Motive a great strong point that results in the development of new products, as the above-mentioned Neo-Pump, or as Neo-Solar, island system for solar pumps and motors.

«A system– underlines Bosio – that we can consider a further development also of Neo-Pump under all respects, offering in its software, in addition to the normal operation aimed at displacing the biggest possible water quantity, like in a water flow irrigation system, the function of operation at constant pressure, for instance for drop by drop irrigation systems».

More in detail, it is an inverter for assembly on motor board, directly powered by solar panels and the novelty consists in the fact that, even if it can operate in “island mode” (that is to say without power supply from the net), it needs no voltage stabilizers and batteries between solar panel and inverter. It can be mounted, for instance, on a pump used in places where the electrical power supply is not available, but also simply to have hot water while saving energy.

«At present – highlights and ends Bosio – there are rare inverters with such performances on the sector market and, besides not being intended for an on-board assembly, they often have high prices. We paid utmost attention to the cost factor in the development of the Neo-Solar, to achieve the best final compromise and to share in relevant savings of electrical consumptions».

SEE ALSO THE VIDEO: https://www.youtube.com/watch?v=zjJV6oSiLDA&feature=youtu.be

In this context, the most common alternative in the solar pump field is to rely on DC motors. Compared to them, Neo Solar can boast some points lead. First, it can operate with a broad array of motors already installed, since these are typically asynchronous AC motors, without calling for their replacement (in fact, the asynchronous motor is by far the most diffused and the cheapest and it can reach notable efficiencies – like IE3). Easily installed and maintained, it is possible to connect the same system simultaneously with solar panels and/or with electric net and/or generator, to compensate a possible insufficient solar irradiation or at night. Moreover, the software of Neo-Solar, called MPST (Max Point Speed Tracker) has been further improved in comparison with standard MPPT (Max Point Power Tracker) systems of the other solar pumps, to achieve a bigger water quantity displacement. A standard MPPT system, in fact, was born for the different target of constantly pursuing a compromise between current and voltage, in order to store the extracted power. MPST by Neo-Solar, instead, focuses on the water result and operates so that the pump regulates the speed and optimizes voltage and current values, to attain the operation in a longer time lapse during the day. Like for Neo-Pump inverters, two executions are currently available for Neo-Solar, one with 3 kW of power and one for powers up to 11 kW.