RomaxDESIGNER for NVH simulation and testing supports the Volkswagen Group to optimise their transmission design and establish integrated validation strategies.

With continued pressure to reduce development time and costs, along with ever-higher consumer expectations and the rise of electric vehicles (EVs) and hybrids, the need to understand and solve NVH issues has become greater than ever. Companies want to quickly and accurately assess the effects of design changes as early as possible in the development cycle – before the process moves into expensive physical prototypes and testing.

Romax Technology has a market-leading simulation software that allows designers and manufacturers to assess and optimize NVH characteristics while also maintaining or improving efficiency and durability, and in a single environment: a powerful integrated approach optimized for design improvements. Issues can be identified at the design stage, checking basic analyses for NVH at a concept level, saving time and money.

Volkswagen Group is one such company that Romax Technology have supported to provide a holistic approach to their design process using RomaxDESIGNER software for gearbox simulation, to perform fast and accurate NVH analysis at each stage of the design and validation.

Europe’s biggest carmaker, Volkswagen Group delivers over 10 million cars to customers each year and has annual group sales revenue (2015) of €202.5 billion. Almost one in four new cars (24.8%) in Western Europe are made by Volkswagen, a group which comprises 12 leading brands from seven European countries: Volkswagen Passenger Cars, Audi, SEAT, ŠKODA, Bentley, Bugatti, Lamborghini, Porsche, Ducati, Volkswagen Commercial Vehicles, Scania and MAN.

Its challenge was to develop a reliable validation strategy for gearbox noise, vibration and harshness (NVH) to allow design changes to be made with confidence, and satisfying the demanding needs of the market-leading brands.

Romax’ whole system simulation environment offers both a prevention and cure strategy for transmission NVH issues. Design from the earliest concept stages with NVH in mind for confidence from the start or use advanced analysis and optimization processes to improve the NVH performance of existing designs, whilst never having to compromise on efficiency or durability.

Employing over 15,000 people, Volkswagen’s primary transmission site at Kassel, Germany, supplies about four million manual and automatic transmissions every year. Volkswagen engineers at Kassel have used RomaxDESIGNER software for more than five years, to support the effective production of gearboxes and to ensure the required NVH quality is achieved. Kassel’s Acoustics and System Simulation department focuses on NVH correlation and simulation: «Our main challenge is gear whine, and the need to support our high acoustic standards,” says Carsten Schmitt, PhD student of Volkswagen’s postgraduate program. «NVH is such an important issue in the industry today because of the rise in electric motor developments, and the simultaneous increase in the production of complex gearboxes. We use RomaxDESIGNER so that we can perform accurate simulation of these new gearbox designs, and assess the NVH performance.»

From trial and error to simulation for development

Previously, sporadic correlation studies on the main parts of a gearbox would be conducted based on eigenfrequencies, which allowed for little correlation guarantee. «We have a requirement to develop simulation models that are representative of the real world, so that our design changes can be made with confidence,» says Schmitt. «This gave rise to the need for an integral validation strategy, which we investigated in RomaxDESIGNER. We have already used the software for over five years on multiple projects. The speed and unique system-level simulation which RomaxDESIGNER offers stand it apart from other products currently available on the market.»

An integral validation strategy

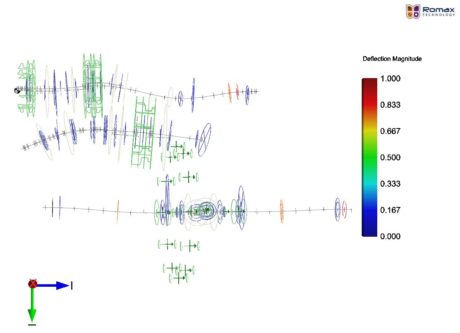

The strategy developed by Volkswagen focuses on a step-by-step process, allowing correlation between measurement and simulation along the acoustic transfer path at each of the following stages: gear excitation, shaft systems, bearings, gearbox housing, and whole vehicle testing. «If test and simulation are compared only at the end of the system development, then it is not possible to work out where discrepancies may arise, hence the need to perform correlation at each level. This gives us an understanding of exactly where problems are occurring, so that we can resolve validation errors quickly and easily, and avoid time-consuming investigatory work,» Schmitt explains. «And Romax software plays a big part in this investigation. Only with RomaxDESIGNER can we quickly and accurately investigate gear whine phenomena on a system level – looking deeper into models to work out where the problems are. This is what allows us to meet high expectations for NVH within even the most cutting-edge system designs. Romax’s unique system level view is a huge benefit to us, as well as its easy-to-use bearing catalogues, which make it easy to model gearboxes even if you are not a bearing expert, and its reliable and accurate transmission error calculations.»

A step-by-step process

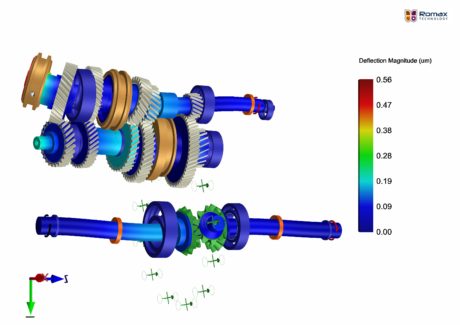

The gears are validated first, with testing and simulation performed across a range of loads. The gear contact pattern is checked; poor correlation indicates either incorrect micro-geometry in the simulation, or deviations in the manufacturing process. The next stage is shaft system validation, which consists of modelling single parts and assemblies, then performing finite element analysis (including pretest analysis and experimental modal analysis, if necessary). This is again validated against test data, and if this is unsuccessful the model must be updated in RomaxDESIGNER. Whenever correlation is not successful, changes can be made which will improve the process for the future, as Schmitt explains: «In the first run we did, we found that the model did need updating. The updates that we performed, including accounting for Young’s modulus and part-to-part stiffness connections, improved the correlation significantly.»

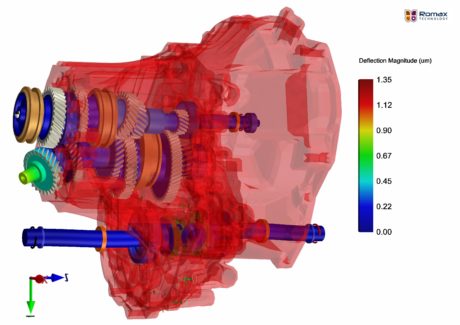

The third stage is correlating the bearing stiffness, and the final step is the correlation for the gearbox housing, for which there are two options, as Schmitt explains: «The validation can be performed by building up the components separately using different tools and testing each individually, and then adding together to make the final model. Alternatively a single model can be created in RomaxDESIGNER, which means just one experimental modal analysis, one correlation analysis, and only one model to update. We found that there was little difference between the methods, so the full housing assembly was done in order to save time and effort – this is a very useful way of doing the correlation.»

«Now we have developed the framework, we are confident that the work that we have put into this implementation will enable time and cost savings for future projects, as well as maintaining our customer’s trust in our ability to deliver their requirements,» Schmitt concludes. «We have developed a clear strategy to perform straightforward model updating procedures, and extended the validity and trust of our Romax gear whine models. Our design changes are not reliant on trial and error, but are based on proven, trustworthy simulation.»

Benefits Summary

- Resolve validation errors quickly and easily through an understanding of exactly where they occurred, removing the need for time-consuming investigatory work.

- Obtain and maintain customer trust – deliver exactly what they require, with confidence

- Meet increasing demands for NVH which satisfy cutting-edge gearbox designs, e.g. for electric motors or complex gearboxes.

- Know that design changes are made not relying on trial and error, but based on proven, trustworthy simulation.

Romax for NVH: what you need to know

- Moving away from ‘traditional’ design and analysis approaches to consider all elements of NVH optimization.

- Taking a whole-system view – to solve NVH issues faster, earlier and in optimal ways.

- Gear whine, gear rattle, efficiency and durability are analyzed simultaneously; when combined with Design of Experiments functionality, multiple iterations can be assessed automatically.

- Reducing prototype and development costs: bringing quieter higher quality products to market faster. http://www.romaxtech.com/