Parker Hannifin at Hannover Messe 2019. Partnering with customers to increase productivity and profitability through engineering innovation

Parker Hannifin, a global leader in motion and control technologies, will present a number of new technology innovations for system solutions, components and services to support and drive sustainable and competitive industrial production at this year’s Hannover Messe.

Visitors to Parker’s booth will find efficient and environmentally friendly innovations for a wide range of applications in hydraulics, pneumatics, electromechanical, filtration, fluid and gas handling.

To highlight Parker Hannifin’s partnership with distributors, six Parker Hannifin distributors from Germany will join Parker on the IAMD booth as sub-exhibitors. Gustav Schmidt, KAINDL Technischer Industriebedarf, Kohler, Otto Glas, PHILIPP and DELTA-Fluid Industrietechnik will each showcase their respective technology and system solution capabilities. In support of greater productivity in diverse industrial applications, machines and processes, Parker with these six distributors will present its valves, pumps, filters, gaskets, hoses, controllers, motors, drives and controls, plus other related components and accessories. The company’s optimised, durable and resource-saving solutions can be combined to offer customers tailor made system solutions from a single source.

Special focus will be on the company’s EcoReach system, Thermal Management solutions and the TFP 2-Way Servo-Proportional Valve Series. Applications in the Future Lab will demonstrate Parker’s systems solutions capabilities as a valued added partner. The area will showcase the company’s capabilities in combining its core technologies to enable OEMs to reduce system complexity and production flow time through effective systems integration.

EcoReach

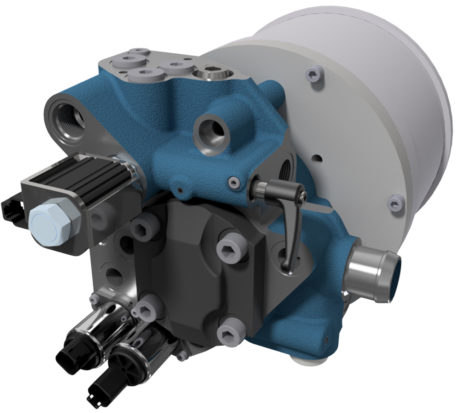

EcoReach is a highly-engineered system combining state-of-the-art core Parker technologies. The result is an integrated hydraulic and traction powertrain system, that delivers vast improvements in performance and efficiency, while at the same time simplifying build procedures and reducing costs for forklift OEMs. The system gives increased battery life, productivity, load handling and operation speed, and a significant reduction in energy consumption.

EcoReach comprises a number of enabling technologies, each of which has been optimised to provide a fully integrated package tailored to the needs of forklift manufacturers and users. Technologies integrated include a PMAC motor that improves load handling and reduces energy consumption, a reversible pump that converts shaft power into hydraulic power and runs as a motor driving the electric motor as a generator, and an optimised valve system featuring a combination of different technologies designed specifically for forklift applications.

EcoReach also features an integrated hydraulic unit with the motor, pump and hydraulic valves all incorporated into a single housing; this minimises the number of components, enhancing reliability and reducing installation size.

The EcoReach forklift assembly system is the highlight of Parker’s traditional hydraulic technology. The electric forklift is handled by an electro-hydraulic system. The powertrain consists of a series of separate components: an inverter that converts battery energy into alternating current; an electric motor that outputs torque and speed; and a hydraulic pump that provides flow and pressure; and a hydraulic system controls the valve block to control the flow and pressure of the required hydraulic function.

Thermal Management

The entire production and product lifecycle of systems and machines is often dependent on efficient cooling to maintain optimum operating temperatures. Parker will show its broad range of thermal management components in its Future Lab area at Hannover. Amongst the technologies on display will be the company’s NSA, NSI, NSE series and various sizes of couplers. These can be combined with Sensonodes (diagnosing, transmission and monitoring devices) and manifolds to build customised thermal management solutions.

Parker quick couplings that can be assembled without tools, to connect cooling elements for the thermal management applications, will also be exhibited. The low pressure drop in these systems helps to optimise energy consumption.

All the products have a flat sealing valve design that allows connection and disconnection without fluid loss.

Maintenance times are shortened significantly thanks to quick coupling and uncoupling. Also, thanks to the shut-off couplings, the fluid can remain in the circuit during maintenance work and does not need to be drained.

New 2-Way Servo-Proportional Valve Series TFP

With its TFP series of cartridge valves, Parker will demonstrate a further innovation in its Future Lab at Hannover Messe. The new 2-way servo proportional valve with VCD® technology is based on the current TDP and TEP families. The TFP series builds on the excellent flow characteristics, precision and dynamics of these existing products to deliver shorter cycle times, more stable processes and minimised scrap rates.

The TFP Series is characterised by a completely new, flow-optimised design. In combination with numerous other technical enhancements, the TFP series achieves flow values that were previously only possible by opting for a larger size valve.

Finally, as a special highlight, Parker will also present the new TFP series as a 3D-printed version. The fully functional valve will clearly demonstrate the exciting possibilities of additive manufacturing.

Learn more at www.parker.com or @parkerhannifin.