Established in 1968, the Italian company Pizzirani is specialized in the distribution of industrial technical products and in the implementation of customized solutions to solve complex problems connected with the power transmission world. The company, set up as technical item reseller, has succeeded in evolving and transforming to satisfy the various market requirements and in 2004 it started the production of some solutions with its own brand, like V and timing belts, pulleys and bushes, rubber sheets, rubber and PVC hoses, chains, adjustable motor mounting and hose clamps.

Three years later, the company was further enlarged with new spaces, so extending the total surface to 9,000 m². Today the Tuscan company, headquartered at Colle Val d’Elsa, in Siena province (Italy), engages about 30 workers and is ready to make new investments, as its founder and President in charge Orlando Pizzirani told us in this interview.

The first six months of the year have been characterized by a neat downturn of all macroeconomic indicators on a global scale, caused by the health emergency followed by the manufacturing lockdown. How did you face this complex international situation?

Certainly, this is a particular year and only the most structured companies have managed to contrast the constant demand drop until now. Our company has well overcome the first half of 2020 through our full product availability and our organizational skills based on a widespread distribution net that has allowed us to guarantee complete supplies to all of our customers.

What are your expectations for next months and the main criticalities you are facing?

Forecasting the future is currently difficult but we are optimistic. The major criticality we are assessing concerns the urgency of providing efficacious feedbacks to the received demands in shorter and shorter terms. In this historical phase, characterized by high uncertainty, it is hard for companies to make long-term plans and therefore they tend “to navigate by sight”.

According to your vision, will there be more recovery possibilities on foreign markets or from the domestic demand?

Foreign markets are potentially more interesting for our company. As we already rely on a good ranking on the Italian market, foreign ones offer us more growth and expansion prospects.

Has the pandemic changed your way of operating and interacting with your customers?

Nothing has changed concerning the sales assistance. Like for everybody, the change regarded the direct relationship with customers and our sale team’s visits, which have thinned out owing to restrictions and rules imposed to contrast the emergency.

Have some corporate changes occurred or do you foresee them?

According to our best service philosophy, we are planning a further enlargement of our warehouses with the construction of a new building. Unfortunately, Italian bureaucracy times clash with the dynamism required by the modern era, we are working at it and we are confident to be ready by the end of 2021. This new warehouse taking up about two thousand square metres will be positioned sideways the already existing units, to create a continuity of spaces and to optimize the management and the collection of products, allowing us to reach over 9,000 square metres of covered space. The interior will be structured with a modular approach, to suit better the stocking of our products that have very different sizes one another. We have items of few centimetres that weigh some grams and even one-metre height components weighing 100 kg.

Have you released some new products and services or are you planning to do that next months?

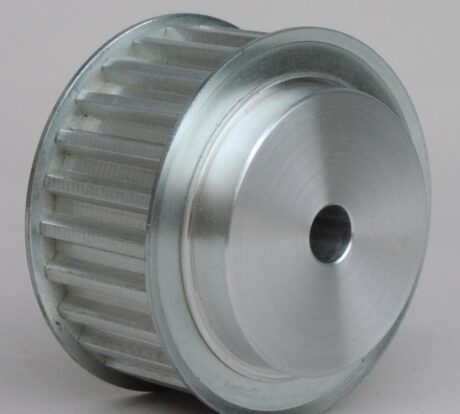

We have optimized some spaces to allow the stocking up of the new range of aluminium and cast iron toothed pulleys, useful products to complete our offer in the transmission sector. This typology of solutions is used on synchronous transmissions that use our rubber and polyurethane timing belts in the XL, L, H inch pitches and 5M, 8M, 14M, T and AT5, T and AT10 metrical ones. Moreover, we have reorganized the management area of polyurethane belts, inaugurating also the cutting and junction service through the welding of belts made of this material, so becoming more autonomous and faster in the offer of this product line.

What are the sectors and the geographical areas where new business opportunities might emerge for your corporate activity?

The market segments where we operate are historical for us: mechanical transmission, then both chains and V- and timing belts, transport chains, adjustable electric motor mounting, and the rubber field, then hoses for the liquid and gas flow and rubber sheets for generic and technical applications. Geographically, East Europe and the Mediterranean area are the zones where our activity is most appreciated.

What are your forecasts for 2020 turnover and expectations for 2021?

This year, we will probably miss a small turnover share related to the few weeks of total activity stop occurred in Spring as, owing to the situation evolution, we do not foresee it can be recovered by the end of the year, but for 2021 we certainly expect a general situation improvement and an upswing of the turnover that we think will be able to exceed the values of 2019-yearend. www.pizzirani.net

[su_box title=”Toothed pulleys”]PIPULLEY toothed pulleys are available in XL, L, H, XH, 3M, 5M, 8M, 14M , T2,5, T5, TlO, AT5, ATlO pitches, in the various widths and in different materials.  They are supplied with small-size cylindrical pre-hole to allow the machining of the shaft seat according to one’s own requirements. The version with seat for tapered bush is available for the most demanded pulley typologies, too[/su_box].

They are supplied with small-size cylindrical pre-hole to allow the machining of the shaft seat according to one’s own requirements. The version with seat for tapered bush is available for the most demanded pulley typologies, too[/su_box].