The noise generated by hydraulic plants is noxious for the numerous creatures that inhabit our oceans. Unfortunately, hydraulic plants are one of the primary causes of this type of acoustic pollution. Nevertheless, the noise silencers of hydraulic nature can reduce the noise generated by hydraulic plants.

Until modern times, oceans and seas were places of loneliness and serenity. We estimate, however, that the noxious noise generated by men in oceans, in particular the one coming from ships, has grown ten times from 1950 to 1975, and today it is increasing at an even more alarming rate. The sound speed in water is four times the speed in atmosphere and the distances that the sound can travel in water are so long that the noise generated by ships can reach marine animals faster than what the atmospheric noise would do. Many marine species exploit sound to communicate, to identify food and to mate. As seas and oceans gradually become noisier, the surviving capability of these animals decreases. According to the scientific data collected, the noise generated by ships notably modifies the behaviour of several marine species, which in the attempt of avoiding these noises often end up stranded. The negative effects of artificial sounds on marine species menace the future generations, too. Some marine species exploit the sound to localize protected restocking areas in rivers and creeks, but the numerous sounds coming from several sources put this capacity in danger. The acoustic stress can also weaken the immune system of dolphins and whales.

How to face the problem

Hydraulic systems are unfortunately one of the primary causes of this type of artificial sound. Ships are generally equipped with various hydraulic plants that, together, share in increasing this noise in exponential manner. The solution of some problems connected with the effective noise reduction will need a global effort. Nevertheless, today we can do a lot at level of single vessel to reduce the noise emitted in water – especially the one generated by hydraulic plants. For the fastening of hydraulic pipes, for instance, the replacement of clamps fully made of metal with damping pipe clamps provided with elastomeric inserts, prevents the propagation of noises and vibrations from hydraulic pipes to the ship frame and hull. To damp the vibrations that otherwise would be transmitted by a hydraulic pump and by an electric motor to the ship, it is also possible to use elastomeric supports. These techniques, however, concern the noise coming from the hydraulic plant. A more effective solution consists in reducing the noise generated by that plant. Wilkes & McLean produces a suppressor of noise and vibrations easily installed in hydraulic lines to reduce drastically the quantity of noise generated by the hydraulic plant. The in-line suppressor reduces the pressure oscillations generated by pumps, levelling the peaks and the valleys of pressure waves. Being bi-directional, this suppressor damps also intermittent hydraulic strokes that can occur when valves shut off suddenly or actuators reach the stroke end or they meet an immobile load.

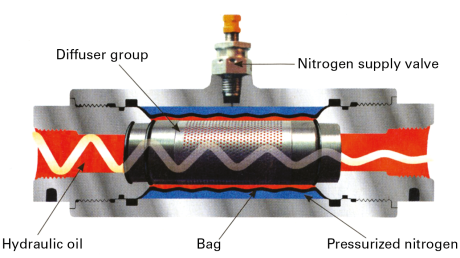

How it operates

The suppressor is constituted by three acoustic metal diffusors of cylindrical shape, concentric, positioned inside a tubular rubber bag pre-charged with nitrogen. The inner diffusor is provided with holes with ½ inch diameter. The second layer consists of a helical spring that contributes in supporting a subtle external diffusor, while another external diffusor is provided with over 4000 holes with 1/32 inch diameter. These tiny holes prevents the bag from being extruded. After propagating in the suppressor, noise pulses pass through the diffusors – at a total radial distance of ¼ of inch only– and hit the bag, which is typically powered at 50-60% of the working pressure of the hydraulic plant. Whenever it is hit by a pulse, the bag shrinks; this slight shrinkage absorbs and reduces pressure pulses and shock waves. The extended bag surface, its capability of oscillating at high frequency and the right distance to be covered share in absorbing pulses with frequencies exceeding 600 Hz. Preventing or reducing the pulses, you decrease the noise generated by the hydraulic plant of the ship.

Silence at the state of the art

Noise Control Engineering at Billerica, Massachusetts, is a company specialized in the design of solutions for the silence of ships. Explains the vice-president Michael Bahtiarian: «Most of oceanographic research vessels require low levels of irradiated noise to use acoustic instruments efficiently. Research ships about fishing, for instance, with an autonomy of 40 days, destined to the National Oceanic and Atmospheric Administration were designed to carry out the assessment of fish stocks with acoustic methods. To use such instruments, it was necessary to reduce the levels of submarine noise.

The FRV-40 ship shown at the beginning complies with the severe noise limits imposes by the International Council for the Exploration of the Sea (ICES)» «To conform to ICRA noise levels» adds Bahtiarian, «a ship requires also an attentive design of the propeller, the insulation of the vibrations generated by machinery and a hull provided with acoustic insulation. The machinery insulation concerns diesel generators, big pumps, air compressors, HVAC systems and hydraulic power units. The vibration insulation of the only hydraulic power units (HPU) might not be sufficient to reduce the noise generated by these machines because the noise (pulse-type) easily travels across hydraulic pipes. Besides, it can travel in both flow directions. The engineers of Noise Control Engineering have ascertained that this noise travels also along static gravity lines. It is necessary to study attentively the arrangement of hydraulic lines, but the use of the Wilkes & McLean suppressor notably shares in reducing such noise». We often report, in fact, a noise reduction by even 17 dB or more.