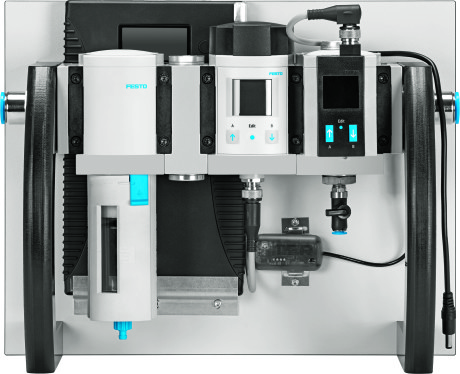

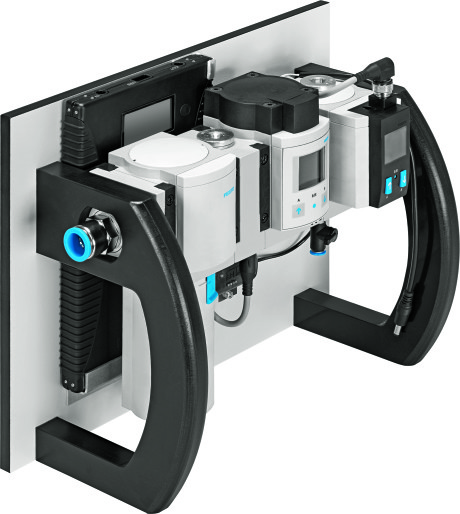

The new air-flow analyser from Festo offers transparency in portable form. Contained in a handy case, this mobile measuring device can be used to measure pressure and flow rates even in system areas that are hard to reach. Thanks to a universal data logger and operator software, the data can be evaluated and stored on any normal PC. Reducing costs thus becomes very straightforward.

If air were water, many plant operators would have wet feet. Air is invisible, has no smell and, since it appears to be available in unlimited quantities, does not seem at first glance to be expensive. It is therefore no wonder that, in the everyday world of work with many systems, far too little thought is given to the efficient use of compressed air. But this can be well worthwhile. Regular inspections of pneumatic systems lower operating costs and increase the efficiency of pneumatic systems and components. A reduction of compressed air losses of as little as 100 l/min. can save up to €1,000 a year.

If air were water, many plant operators would have wet feet. Air is invisible, has no smell and, since it appears to be available in unlimited quantities, does not seem at first glance to be expensive. It is therefore no wonder that, in the everyday world of work with many systems, far too little thought is given to the efficient use of compressed air. But this can be well worthwhile. Regular inspections of pneumatic systems lower operating costs and increase the efficiency of pneumatic systems and components. A reduction of compressed air losses of as little as 100 l/min. can save up to €1,000 a year.

Compact measurement competency

With the new air-flow analyser from Festo saving energy and reducing costs is really simple. That is because it is a mobile device which, in its practical and tough case, can be carried to all kinds of measuring points. It can then be connected up quickly on the spot to deliver dependable measurement data within a very short time. When integrated directly into the compressed air supply line of a system, the air-flow analyser offers compact measurement competency in a handy form for flexible use throughout a plant.

Efficient and flexible

The air-flow analyser makes compressed air visible. Consumption and flow rate data for a plant can be recorded and evaluated efficiently and flexibly. Designed in accordance with Festo’s well-proven plug & work principle, this mobile measuring device has everything which is needed for efficient leak management: a 40 µm filter to protect the sensor elements, a flow rate sensor for values from 30 to 3,000 l/min., a pressure sensor for up to 10 bar, a data logger for 2 million data records, evaluation software and a rechargeable LiPo battery rated at 21,000 mAh. Pressure and flow rate measurements are taken at the same time.

The air-flow analyser creates a reliable database for sustainable energy efficiency measures, whether these involve compressed air analysis at machine level as part of a preventive maintenance programme for existing plants or documentation of precise consumption data for new plants. The progress achieved with individual optimisation measures can be recorded for the purposes of Total Productive Maintenance, thus avoiding potential errors.

For use in the field

It is not only its compact size which makes this mobile measuring device particularly flexible to use. Its universal data logger ensures that the acquired data can be processed further easily and at any location. After measurements have been taken, the results can be transferred quickly and easily to a PC. The operator software of the air-flow analyser for data recording and convenient data evaluation on a PC has been specially designed for use in the field. It guarantees precise measured data recording and visualisation and is always up-to-date, thanks to regular online updates.

(Photos: Festo AG & Co. KG)