The art of being able to manufacture tailor-made components. It is the element that characterizes Telcomec, an Italian company specialized in the design and manufacturing of motion transmission solutions.

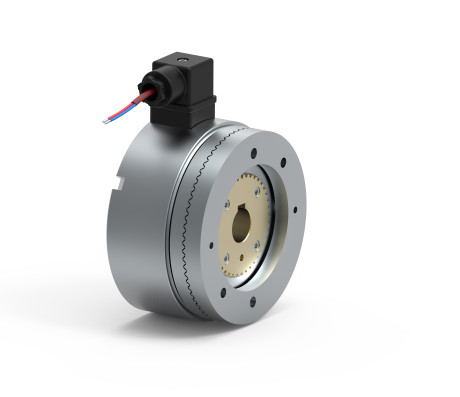

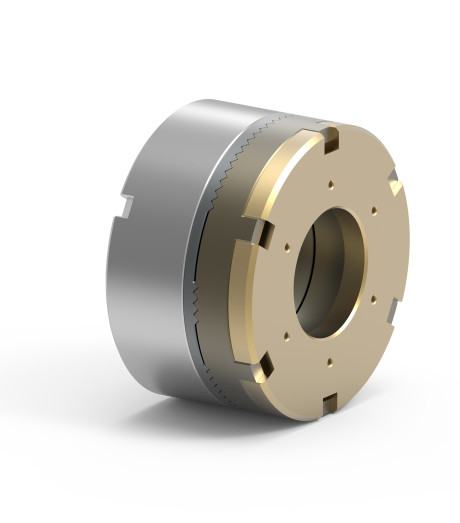

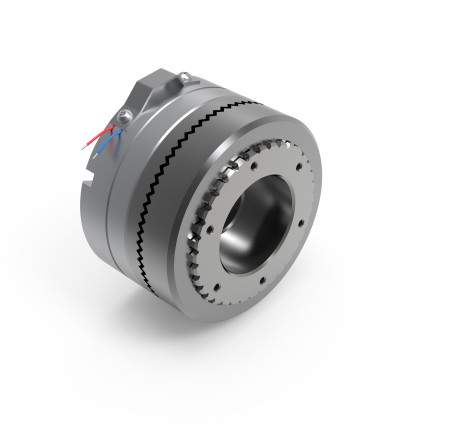

A small company established in the core of Emilia and founded in 1993 by four members who decided to share their twenty-year experience and their expertise in the mechanical component field. It was so born Telcomec, company with headquarters at Lippo di Calderara (Bologna, Italy), specialized in the design and production of motion transmission solutions: clutches, brakes, electrically or pneumatically commanded or released tooth and disc clutches and brush contact tips.

Over the years, the company has grown and today it attains 60% of its turnover on the Italian market while 40% derives from the sales abroad. «Starting from the late Nineties we have started participating in various sector exhibitions worldwide, from Germany to Romania, from Russia to Brazil – explained Vincenzo Tomasi, Managing Director of the company – This investment has allowed us to extend our action and to give visibility to our company and to our products all over the world».

One motor, endless sectioned connections

«The global market more and more often asks for customized and very specific products. We often start from a standard catalogue solution that is however adapted» is the first remark by Tomasi, while showing the new catalogue just completed by 40 new pages.

«Our company, as soon as established, specialized in the production of electrically or pneumatically controlled clutches, tooth-, disk- and friction material clutches with a range of articles granting a selection of torque performances varying from 2 Nm to 18,000 Nm» explained the manager. The application sectors of our solutions go from packaging to textile, from the building industry to the ceramic field as well as to the most various automation applications like, for instance, the implementation of roller conveyors with the use of a single electrical drive motor and the use of a Telcomec clutch for each single motion. «Over the last few years we have developed and implemented our range of products making them much more versatile and cheap to satisfy the demands by our customers widespread all over the world and we believe that this is the challenge of the future». Telcomec’s entire production is manufactured in Italy, the company avails itself of forefront automated technologies and of a net of subcontractors specialized in several machining typologies: «We pay utmost attention to choosing always the most performing raw materials – specified Tomasi – Besides, we carry out the quality control and the tests in-house. We grant flexibility and fast delivery terms just thanks to the strict collaboration relationships with local artisans». Another strong point of the company is the warehouse, always ready and well-stocked with semi-finished products that, with small finishes, are ready for assembly. «Nowadays machine manufacturers cannot plan their activities anymore – added the manager – In the past delivery terms could be even several months. Today dozens of days maximum are at stake. We must be flexible and snappy».

Customized automation solutions

The company relies on a technical office that provides consulting and support in the design and implementation of whatever automation type, from simplest standard solutions to the most complex customized ones.

«We support our customers with the supply of CAD designs in 3D and assembly videos – specified the Managing Director – Before starting developing a new project we organize a preliminary technical meeting to evaluate customers’ requests and application specificities. Then we develop the project and we propose the solution, from the test prototype up to the mass production». In the history of Telcomec there are several successful application cases: «We have devised some solutions that called for notable design commitment for the automation of transport systems in some military airports. Another applicative case that required an accurate preliminary study phase concerned the development of an electromagnetic tooth clutch able to transmit a high torque with small footprint, to grant the opening and closing of doors in dangerous environments with remote control». Almost all products are a new solution: «Just recently we have updated the catalogue, quite often it happens that we develop a solution for one customer and afterwards it widens our standard range».

From Europe to Asia

Over the last few years, the development of Telcomec has followed two directions: the strengthening of its presence abroad and the range extension.

«We satisfy the Italian market’s requirements through a structure of agents and resellers – explained the Managing Director – Abroad, instead, we are well-rooted in Europe and operating through a net of agents and resellers in various Countries. In the first six months of 2015 sales were positive in France, Holland and Czech Republic. Even if the first results of this year were successful, it is not possible to make forecasts for the future». Among the most appealing and promising outlets towards which Telcomec is addressing huge investments there is the Asian area. «We have a reseller in Shanghai and Taiwan. This enormous market calls for high-quality products, high performances, low costs and very short delivery terms» specified Vincenzo Tomasi.

SEE ALSO THE VIDEO: https://www.youtube.com/watch?v=Z5oyDd4wt88