RobotCustom is the new operational division through which Excogita operates side by side with the market to design and to manufacture high added-value robotic systems, highly customized.

It proposes itself as qualified structure that can be for instance addressed by standard machine manufacturers, to allow them the integration of robot automations highly customized according to the specific requirement, overcoming the conventional integration method of standard robots, integrating, as alternative, its own robot mechanics, managed with its own standard motors generally used. An approach that allows obtaining complete integration, utmost performance and low costs.

How does RobotCustom operate?

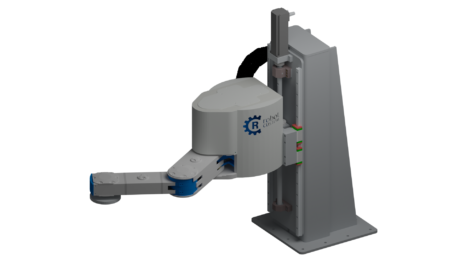

«RobotCustom – explains the managing director of Excogita, the engineer Mirco Ronci – designs robotics customized upon precise specification, perfectly integrating it into the manufacturer’s line or machine project, choosing its own colour and putting its own brand. The design starts from the matching of primary elements, parts or systems more than tested, developed and implemented by Excogita in many years of machine design. These parts make up our scalable starting robots, that is to say Scara robots, Delta robots, Palletizers and so on, which we show as typical solutions».

What are the highlights of this manufacturing methodology?

«One of the strong points – the engineer Ronci points out– resides in the possibility of integrating robotics inside the machines produced by our customers in compliance with the available footprint. In this way, the overall dimensions are minimized. Another stronghold is that the whole design is oriented to the use of standard motors and drives chosen by customers according to their programming technology used for interpolation, for instance Plc, Pac, Cnc. Therefore, not with imposed use as it usually happens, but leaving utmost total choice freedom to customers. Once defined the expected performance requisites, RobotCustom can supply a complete pre-assembled mechanical system, ready for installation, with or without motors, with customized aesthetics and logo, with agreed delivery or according to a pre-established programme».

What are the advantages and the benefits deriving from this operational freedom?

«Relying on mechanics disconnected from electronics – Mr Ronci highlights – means not being bound to the use of specific motors, rather than to the use of a single brand. The plus is the possibility of buying what the market offers in short times and at the best price, exclusively staking on the satisfaction of the requisites demanded for that specific application. Moreover, it is worth highlighting that, compared to standard robots, those implemented by RobotCustom are perfectly calibrated at functional and operational level, exclusively to provide some determinate performances. Therefore, it is not necessary to adapt the machines to the standard market robotics but precisely the opposite. In the opinion of RobotCustom, robotics must adapt itself, hence the slogan “the right robot for everyone”.

How does RobotCustom implement robotics customized according to the single requirement?

«On the basis of the cross-ranging expertise gained in almost twenty years of activity – Mr Ronci confirms and ends – through RobotCustom we have structured a product basis from which tailoring the robotic system according to the most different market requirements. I am referring to modular scalable Scara robots, multi-linear Delta systems, column palletizers and planar robots that, owing to their intrinsic peculiarities, can offer targeted performances. Performances that, due to the design and executive concept that resides on the grounds of RobotCustom, starting from a standard solution, can be further developed, to full benefit of more competitiveness for each application».

Therefore, Umbria company can design, manufacture and assemble the various functional elements starting from a standard solution, refining it from time to time depending on the specific application, according to the loads to be handled, modulating and customizing work ranges, purposely studying the support structure (on the ground, ceiling or shelf), integrating it into the available spaces wished by the customers that manufacture machines, with possibility of designing and implementing also customized gripping systems (not only grippers but also vacuum or pneumatically-operated magnetic gripping equipment).

(by Gianandrea Mazzola)